Related Research Articles

Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures to a solid over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminium combined.

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and is usually made from limestone. It is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, and then grinding the clinker with the addition of several percent gypsum. Several types of portland cement are available. The most common, historically called ordinary portland cement (OPC), is grey, but white portland cement is also available. Its name is derived from its resemblance to Portland stone which is quarried on the Isle of Portland in Dorset, England. It was named by Joseph Aspdin who obtained a patent for it in 1824. His son William Aspdin is regarded as the inventor of "modern" portland cement due to his developments in the 1840s.

Reinforced concrete, also called ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars (rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion.

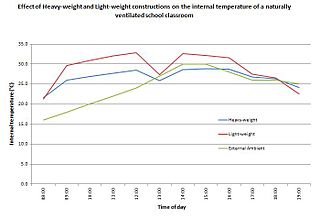

In building design, thermal mass is a property of the matter of a building that requires a flow of heat in order for it to change temperature. In scientific writing the term "heat capacity" is preferred. It is sometimes known as the thermal flywheel effect. The thermal mass of heavy structural elements can be designed to work alongside a construction's lighter thermal resistance components to create energy efficient buildings.

Building material is material used for construction. Many naturally occurring substances, such as clay, rocks, sand, wood, and even twigs and leaves, have been used to construct buildings and other structures, like bridges. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

A gravity dam is a dam constructed from concrete or stone masonry and designed to hold back water by using only the weight of the material and its resistance against the foundation. Gravity dams are designed so that each section of the dam is stable and independent of any other dam section.

Lime is an inorganic material composed primarily of calcium oxides and hydroxides. It is also the name for calcium oxide which occurs as a product of coal-seam fires and in altered limestone xenoliths in volcanic ejecta. The International Mineralogical Association recognizes lime as a mineral with the chemical formula of CaO. The word lime originates with its earliest use as building mortar and has the sense of sticking or adhering.

Hydraulic lime (HL) is a general term for a variety of lime different from calcium oxide, also called quicklime, that sets by hydration and consists of Calcium Silicate and Calcium Aluminate, compounds that can harden in contact with water. This contrasts with calcium hydroxide, also called slaked lime or air lime that is used to make lime mortar, the other common type of lime mortar, which sets by carbonation (re-absorbing carbon dioxide (CO2) from the air). Hydraulic lime provides a faster initial set and higher compressive strength than air lime, and hydraulic lime will set in more extreme conditions, including under water.

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving.

Engineered Cementitious Composite (ECC), also called Strain Hardening Cement-based Composites (SHCC) or more popularly as bendable concrete, is an easily molded mortar-based composite reinforced with specially selected short random fibers, usually polymer fibers. Unlike regular concrete, ECC has a tensile strain capacity in the range of 3–7%, compared to 0.01% for ordinary portland cement (OPC) paste, mortar or concrete. ECC therefore acts more like a ductile metal material rather than a brittle glass material, leading to a wide variety of applications.

Lime mortar or torching is a masonry mortar composed of lime and an aggregate such as sand, mixed with water. It is one of the oldest known types of mortar, used in ancient Rome and Greece, when it largely replaced the clay and gypsum mortars common to ancient Egyptian construction.

The water–cement ratio is the ratio of the mass of water to the mass of cement used in a concrete mix:

Cement clinker is a solid material produced in the manufacture of portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering limestone and aluminosilicate materials such as clay during the cement kiln stage.

Roman concrete, also called opus caementicium, was used in construction in ancient Rome. Like its modern equivalent, Roman concrete was based on a hydraulic-setting cement added to an aggregate.

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs.

Concrete degradation may have many different causes. Concrete is mostly damaged by the corrosion of reinforcement bars due to the carbonatation of hardened cement paste or chloride attack under wet conditions. Chemical damage is caused by the formation of expansive products produced by chemical reactions, by aggressive chemical species present in groundwater and seawater, or by microorganisms Other damaging processes can also involve calcium leaching by water infiltration, physical phenomena initiating cracks formation and propagation, fire or radiant heat, aggregate expansion, sea water effects, leaching, and erosion by fast-flowing water.

Concrete has relatively high compressive strength, but significantly lower tensile strength. The compressive strength is typically controlled with the ratio of water to cement when forming the concrete, and tensile strength is increased by additives, typically steel, to create reinforced concrete. In other words we can say concrete is made up of sand, ballast, cement and water.

Creep and shrinkage of concrete are two physical properties of concrete. The creep of concrete, which originates from the calcium silicate hydrates (C-S-H) in the hardened Portland cement paste, is fundamentally different from the creep of metals and polymers. Unlike the creep of metals, it occurs at all stress levels and, within the service stress range, is linearly dependent on the stress if the pore water content is constant. Unlike the creep of polymers and metals, it exhibits multi-months aging, caused by chemical hardening due to hydration which stiffens the microstructure, and multi-year aging, caused by long-term relaxation of self-equilibrated micro-stresses in the nano-porous microstructure of the C-S-H. If concrete is fully dried, it does not creep, but it is next to impossible to dry concrete fully without severe cracking.

Energetically modified cements (EMCs) are a class of cements made from pozzolans, silica sand, blast furnace slag, or Portland cement. The term "energetically modified" arises by virtue of the mechanochemistry process applied to the raw material, more accurately classified as "high energy ball milling" (HEBM). At its simplest this means a milling method that invokes high kinetics by subjecting "powders to the repeated action of hitting balls" as compared to (say) the low kinetics of rotating ball mills. This causes, amongst others, a thermodynamic transformation in the material to increase its chemical reactivity. For EMCs, the HEBM process used is a unique form of specialised vibratory milling discovered in Sweden and applied only to cementitious materials, here called "EMC Activation".

Cement hydration and strength development mainly depend on two silicate phases: tricalcium silicate (C3S) (alite), and dicalcium silicate (C2S) (belite). Upon hydration, the main reaction products are calcium silicate hydrates (C-S-H) and calcium hydroxide Ca(OH)2, written as CH in the cement chemist notation. C-S-H is the phase playing the role of the glue in the cement hardened paste and responsible of its cohesion. Cement also contains two aluminate phases: C3A and C4AF, respectively the tricalcium aluminate and the tetracalcium aluminoferrite. C3A hydration products are AFm, calcium aluminoferrite monosulfate, and ettringite, a calcium aluminoferrite trisulfate (AFt). C4AF hydrates as hydrogarnet and ferrous ettringite.

References

- ↑ ACI Committee 207–Mass and Thermally Controlled Concrete

- ↑ Urquhart, Denis (2013). (huanhi) "Historic Concrete in Scotland Part 1: History and Development" Archived 2016-03-04 at the Wayback Machine Historic Scotland, National Conservation Centre, ISBN 978-1-84917-119-9, p. 9