A hydrogen infrastructure is the infrastructure of points of hydrogen production, truck and pipeline transport, and hydrogen stations for the distribution and sale of hydrogen fuel, [1] and thus a crucial prerequisite before a successful commercialization of fuel cell technology. [2]

Contents

- Network

- Hydrogen highways and stations

- Hydrogen pipeline transport

- Hydrogen production plants

- Hydrogen pipeline transport 2

- History

- Economics

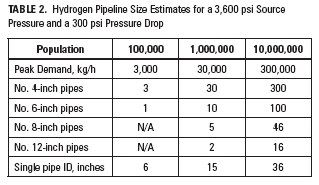

- Piping

- Infrastructure

- Hydrogen highway

- Supply issues, cost and pollution

- Hydrogen station

- Delivery methods

- Types of recharging stations

- Disadvantages

- Locations

- Hydrogen tank

- Low-pressure tanks

- Type I

- Type II

- Type III

- Type IV

- Type V

- Tank testing and safety considerations

- Metal hydride storage tank

- See also

- References

- Sources

- External links

![Hydrogen gasification plant for Belinka Perkemija [sl], 2015 Soteska Ljubljana Slovenia - factory.JPG](http://upload.wikimedia.org/wikipedia/commons/thumb/e/e3/Soteska_Ljubljana_Slovenia_-_factory.JPG/330px-Soteska_Ljubljana_Slovenia_-_factory.JPG)

Hydrogen stations which are not situated near a hydrogen pipeline get supply via compressed hydrogen tube trailers, liquid hydrogen trailers, liquid hydrogen tank trucks or dedicated onsite production. Pipelines are the cheapest way to move hydrogen over long distances but must be designed to withstand the leakage and steel embrittlement caused by the hydrogen molecule. Hydrogen gas piping is routine in large oil-refineries, because hydrogen is used to hydrocrack fuels from crude oil. The IEA recommends existing industrial ports be used for production and natural gas pipelines for transport, international co-operation and shipping. [3]

South Korea and Japan, [4] which as of 2019 lacked international electrical interconnectors, were investing in the hydrogen economy. [5] In March 2020, the Fukushima Hydrogen Energy Research Field was opened in Japan, claiming to be the world's largest hydrogen production facility. [6] Much of the site is occupied by a solar array; power from the grid is also used for electrolysis of water to produce hydrogen fuel. [7]