A tension-leg platform (TLP) or extended tension leg platform (ETLP) is a vertically moored floating structure normally used for the offshore production of oil or gas, and is particularly suited for water depths greater than 300 metres and less than 1500 metres. Use of tension-leg platforms has also been proposed for offshore wind turbines.

Enercon GmbH is a wind turbine manufacturer based in Aurich, Lower Saxony, Germany. It has been the market leader in Germany since the mid-1990s. Enercon has production facilities in Germany, Brazil, India, Canada, Turkey and Portugal. In June 2010, Enercon announced that they would be setting up Irish headquarters in Tralee.

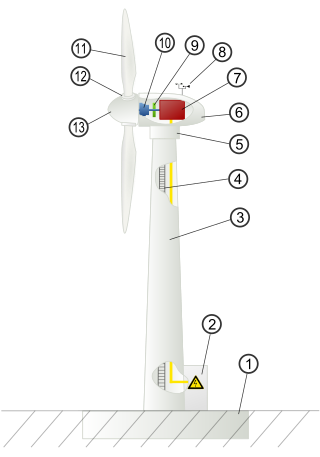

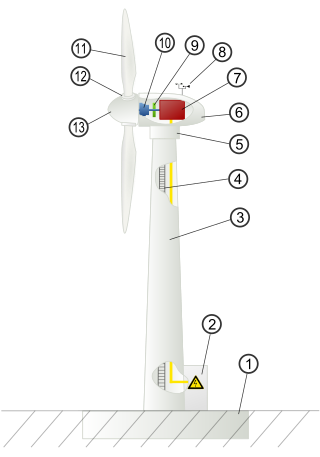

Wind turbine design is the process of defining the form and configuration of a wind turbine to extract energy from the wind. An installation consists of the systems needed to capture the wind's energy, point the turbine into the wind, convert mechanical rotation into electrical power, and other systems to start, stop, and control the turbine.

Unconventional wind turbines are those that differ significantly from the most common types in use.

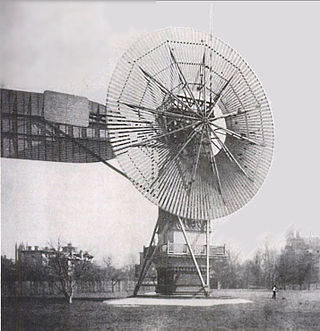

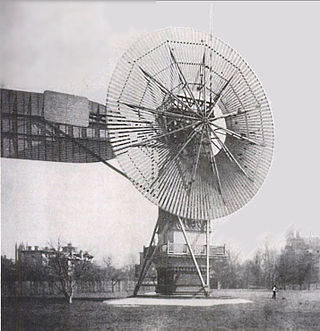

Wind power has been used as long as humans have put sails into the wind. King Hammurabi's Codex already mentioned windmills for generating mechanical energy. Wind-powered machines used to grind grain and pump water, the windmill and wind pump, were developed in what is now Iran, Afghanistan, and Pakistan by the 9th century. Wind power was widely available and not confined to the banks of fast-flowing streams, or later, requiring sources of fuel. Wind-powered pumps drained the polders of the Netherlands, and in arid regions such as the American mid-west or the Australian outback, wind pumps provided water for livestock and steam engines.

Siemens Gamesa Renewable Energy S.A., formerly Gamesa Corporación Tecnológica S.A. and Grupo Auxiliar Metalúrgico S.A., is a Spanish-German wind engineering company based in Zamudio, Biscay, Spain. In Spain, the company has two other main sites one in Madrid and the other one in Sarriguren (Navarre). The Services Commercial Office is located in the Parque de la Innovación de Navarra in Sarriguren. It manufactures wind turbines and provides onshore and offshore wind services. It is the world's second largest wind turbine manufacturer.

The Wild Horse Wind Farm is a 273-megawatt wind farm that generates energy for Puget Sound Energy that consists of one hundred twenty seven 1.8-megawatt Vestas V80 turbines and twenty two 2.0-megawatt Vestas V80 turbines on a 10,800-acre (4,400 ha) site in Kittitas County, Washington, 17 miles (27 km) east of Ellensburg, Washington. The turbines are placed on the high open Shrub-steppe ridge tops of Whiskey Dick Mountain, which was chosen for its energetic wind resource, remote location, and access to nearby power transmission lines. The towers are 221 feet (67 m) tall, and each blade is 129 feet (39 m) long, with a total rotor diameter of 264 feet (80 m), larger than the wingspan of a Boeing 747. The turbines can begin producing electricity with wind speeds as low as 9 mph (14 km/h) and reach full production at 31 mph (50 km/h). They shut down at sustained wind speeds of 56 mph (90 km/h). The site is also home to one of the largest solar array (500 kW) in Washington.

Wind power in Ohio has a long history, and as of 2016, Ohio had 545 megawatts (MW) of utility-scale wind power installations installed, responsible for 1.1% of in-state electricity generated. Over 1000 MW more were under construction or pending approval. Some installations have become tourist attractions. There has been a sudden increase in generating capacity, as total wind power capacity in the state was just 9.7 MW in 2010. By 2019, there were 738 MW of capacity, which generated 1.71% of Ohio's electricity.

A floating wind turbine is an offshore wind turbine mounted on a floating structure that allows the turbine to generate electricity in water depths where fixed-foundation turbines are not feasible. Floating wind farms have the potential to significantly increase the sea area available for offshore wind farms, especially in countries with limited shallow waters, such as Japan, France and US West coast. Locating wind farms further offshore can also reduce visual pollution, provide better accommodation for fishing and shipping lanes, and reach stronger and more consistent winds.

SeaGen was the world's first large scale commercial tidal stream generator. It was four times more powerful than any other tidal stream generator in the world at the time of installation. It was successfully decommissioned by SIMEC Atlantis Energy Limited in summer 2019, having exported 11.6GWh to the grid since 2008.

A wind turbine is a device that converts the kinetic energy of wind into electrical energy. As of 2020, hundreds of thousands of large turbines, in installations known as wind farms, were generating over 650 gigawatts of power, with 60 GW added each year. Wind turbines are an increasingly important source of intermittent renewable energy, and are used in many countries to lower energy costs and reduce reliance on fossil fuels. One study claimed that, as of 2009, wind had the "lowest relative greenhouse gas emissions, the least water consumption demands and the most favorable social impacts" compared to photovoltaic, hydro, geothermal, coal and gas energy sources.

GE Offshore Wind is a joint venture with Alstom and a subsidiary of GE Renewable Energy, created in 2015 when most of Alstom's electrical power and generation assets were acquired by General Electric. GE's stake in the joint venture is 50% plus 1 share.

GE Wind Energy is a branch of GE Renewable Energy, a subsidiary of General Electric. The company manufactures and sells wind turbines to the international market. In 2018, GE was the fourth largest wind turbine manufacturer in the world.

Ming Yang Wind Power Group Limited is the largest private wind turbine manufacturer in China and the fifth largest overall in the country. The company was listed on the New York Stock Exchange from 1 October 2010 to June 22, 2016. It is developing the world's largest wind turbine with a capacity of 18 MW.

The following outline is provided as an overview of and topical guide to wind energy:

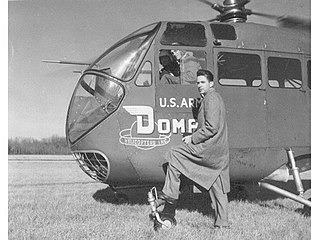

Glidden Doman was an American aeronautical engineer and pioneer in helicopters and modern wind turbines. He founded one of America's original six helicopter companies after making major contributions to the use of Sikorsky helicopters during World War II. Doman Helicopters' most prominent achievement was the Doman LZ-5/YH-31 eight-place helicopter, which received FAA certification on December 30, 1955. The unique feature of this helicopter was its hinge-less but gimbaled, tilting rotor hub that greatly reduced stress and vibration in the blades and in the whole helicopter.

Seawind Ocean Technology B.V., a Netherlands based company, is a manufacturer (OEM) of integrated floating wind turbine and green hydrogen systems. Seawind is developing two-bladed floating wind turbines suitable for installation in all seas, including hurricane regions and ultra-deep waters. Founded on original research and development work by NASA, Hamilton Standard, Enel, and Aeritalia; Seawind's offshore wind power turbines with integrated foundations have been patented, proven at 1.5 MW, and achieved Type D DNV certification in December 2019. The company is now planning the launch of its Seawind 6 demonstrator to be followed by the pre-series Seawind 12, a project earmarked for installation as early as 2024-25 that seeks to obtain DNV's highest certification level.

The Gamma 60 wind turbine, a 1.5 MW two-bladed upwind horizontal axis wind turbine, was installed by Wind Energy Systems Taranto S.p.A. (WEST) at Alta Nurra, Sardinia, Italy in April 1992. Founded on original research and development work by NASA and Hamilton Standard, the Gamma 60 wind turbine was the world's first variable speed wind turbine with a teetering hinge.