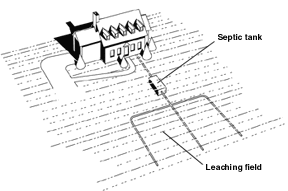

A septic tank is an underground chamber made of concrete, fiberglass, or plastic through which domestic wastewater (sewage) flows for basic sewage treatment. Settling and anaerobic digestion processes reduce solids and organics, but the treatment efficiency is only moderate. Septic tank systems are a type of simple onsite sewage facility. They can be used in areas that are not connected to a sewerage system, such as rural areas. The treated liquid effluent is commonly disposed in a septic drain field, which provides further treatment. Nonetheless, groundwater pollution may occur and can be a problem.

Wastewater treatment is a process which removes and eliminates contaminants from wastewater and converts this into an effluent that can be returned to the water cycle. Once returned to the water cycle, the effluent creates an acceptable impact on the environment or is reused for various purposes. The treatment process takes place in a wastewater treatment plant. There are several kinds of wastewater which are treated at the appropriate type of wastewater treatment plant. For domestic wastewater, the treatment plant is called a Sewage Treatment. For industrial wastewater, treatment either takes place in a separate Industrial wastewater treatment, or in a sewage treatment plant. Further types of wastewater treatment plants include Agricultural wastewater treatment and leachate treatment plants.

A composting toilet is a type of dry toilet that treats human waste by a biological process called composting. This process leads to the decomposition of organic matter and turns human waste into compost-like material. Composting is carried out by microorganisms under controlled aerobic conditions. Most composting toilets use no water for flushing and are therefore called "dry toilets".

A constructed wetland is an artificial wetland to treat sewage, greywater, stormwater runoff or industrial wastewater. It may also be designed for land reclamation after mining, or as a mitigation step for natural areas lost to land development. Constructed wetlands are engineered systems that use the natural functions of vegetation, soil, and organisms to provide secondary treatment to wastewater. The design of the constructed wetland has to be adjusted according to the type of wastewater to be treated. Constructed wetlands have been used in both centralized and decentralized wastewater systems. Primary treatment is recommended when there is a large amount of suspended solids or soluble organic matter.

Waste stabilization ponds are ponds designed and built for wastewater treatment to reduce the organic content and remove pathogens from wastewater. They are man-made depressions confined by earthen structures. Wastewater or "influent" enters on one side of the waste stabilization pond and exits on the other side as "effluent", after spending several days in the pond, during which treatment processes take place.

The activated sludgeprocess is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using aeration and a biological floc composed of bacteria and protozoa. It uses air and microorganisms to biologically oxidize organic pollutants, producing a waste sludge containing the oxidized material.

Septic drain fields, also called leach fields or leach drains, are subsurface wastewater disposal facilities used to remove contaminants and impurities from the liquid that emerges after anaerobic digestion in a septic tank. Organic materials in the liquid are catabolized by a microbial ecosystem.

Onsite sewage facilities (OSSF), also called septic systems, are wastewater systems designed to treat and dispose of effluent on the same property that produces the wastewater, in areas not served by public sewage infrastructure.

Upflow anaerobic sludge blanket (UASB) technology, normally referred to as UASB reactor, is a form of anaerobic digester that is used for wastewater treatment.

Secondary treatment is the removal of biodegradable organic matter from sewage or similar kinds of wastewater. The aim is to achieve a certain degree of effluent quality in a sewage treatment plant suitable for the intended disposal or reuse option. A "primary treatment" step often precedes secondary treatment, whereby physical phase separation is used to remove settleable solids. During secondary treatment, biological processes are used to remove dissolved and suspended organic matter measured as biochemical oxygen demand (BOD). These processes are performed by microorganisms in a managed aerobic or anaerobic process depending on the treatment technology. Bacteria and protozoa consume biodegradable soluble organic contaminants while reproducing to form cells of biological solids. Secondary treatment is widely used in sewage treatment and is also applicable to many agricultural and industrial wastewaters.

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter. The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

Effective microorganisms (EM) are various blends of common predominantly anaerobic microorganisms in a carbohydrate-rich liquid carrier substrate of EM Research Organization, Inc.,

An aerobic treatment system (ATS), often called an aerobic septic system, is a small scale sewage treatment system similar to a septic tank system, but which uses an aerobic process for digestion rather than just the anaerobic process used in septic systems. These systems are commonly found in rural areas where public sewers are not available, and may be used for a single residence or for a small group of homes.

A trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous. The treatment of sewage or other wastewater with trickling filters is among the oldest and most well characterized treatment technologies.

Sewage treatment is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable to discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution from raw sewage discharges. Sewage contains wastewater from households and businesses and possibly pre-treated industrial wastewater. There are a high number of sewage treatment processes to choose from. These can range from decentralized systems to large centralized systems involving a network of pipes and pump stations which convey the sewage to a treatment plant. For cities that have a combined sewer, the sewers will also carry urban runoff (stormwater) to the sewage treatment plant. Sewage treatment often involves two main stages, called primary and secondary treatment, while advanced treatment also incorporates a tertiary treatment stage with polishing processes and nutrient removal. Secondary treatment can reduce organic matter from sewage, using aerobic or anaerobic biological processes.

Sludge is a semi-solid slurry that can be produced from a range of industrial processes, from water treatment, wastewater treatment or on-site sanitation systems. For example, it can be produced as a settled suspension obtained from conventional drinking water treatment, as sewage sludge from wastewater treatment processes or as fecal sludge from pit latrines and septic tanks. The term is also sometimes used as a generic term for solids separated from suspension in a liquid; this soupy material usually contains significant quantities of interstitial water. Sludge can consist of a variety of particles, such as animal manure.

Fecal sludge management (FSM) is the storage, collection, transport, treatment and safe end use or disposal of fecal sludge. Together, the collection, transport, treatment and end use of fecal sludge constitute the "value chain" or "service chain" of fecal sludge management. Fecal sludge is defined very broadly as what accumulates in onsite sanitation systems and specifically is not transported through a sewer. It is composed of human excreta, but also anything else that may go into an onsite containment technology, such as flushwater, cleansing materials, menstrual hygiene products, grey water, and solid waste. Fecal sludge that is removed from septic tanks is called septage.

A vermifilter is an aerobic treatment system, consisting of a biological reactor containing media that filters organic material from wastewater. The media also provides a habitat for aerobic bacteria and composting earthworms that purify the wastewater by removing pathogens and oxygen demand. The "trickling action" of the wastewater through the media dissolves oxygen into the wastewater, ensuring the treatment environment is aerobic for rapid decomposition of organic substances.

Decentralized wastewater systems convey, treat and dispose or reuse wastewater from small and low-density communities, buildings and dwellings in remote areas, individual public or private properties. Wastewater flow is generated when appropriate water supply is available within the buildings or close to them.