A rocket is a vehicle that uses jet propulsion to accelerate without using any surrounding air. A rocket engine produces thrust by reaction to exhaust expelled at high speed. Rocket engines work entirely from propellant carried within the vehicle; therefore a rocket can fly in the vacuum of space. Rockets work more efficiently in a vacuum and incur a loss of thrust due to the opposing pressure of the atmosphere.

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program name was Space Transportation System (STS), taken from the 1969 plan led by U.S. Vice President Spiro Agnew for a system of reusable spacecraft where it was the only item funded for development.

A single-stage-to-orbit (SSTO) vehicle reaches orbit from the surface of a body using only propellants and fluids and without expending tanks, engines, or other major hardware. The term exclusively refers to reusable vehicles. To date, no Earth-launched SSTO launch vehicles have ever been flown; orbital launches from Earth have been performed by either fully or partially expendable multi-stage rockets.

A mass driver or electromagnetic catapult is a proposed method of non-rocket spacelaunch which would use a linear motor to accelerate and catapult payloads up to high speeds. Existing and proposed mass drivers use coils of wire energized by electricity to make electromagnets, though a rotary mass driver has also been proposed. Sequential firing of a row of electromagnets accelerates the payload along a path. After leaving the path, the payload continues to move due to momentum.

The aerospike engine is a type of rocket engine that maintains its aerodynamic efficiency across a wide range of altitudes. It belongs to the class of altitude compensating nozzle engines. Aerospike engines were proposed for many single-stage-to-orbit (SSTO) designs. They were a contender for the Space Shuttle main engine. However, as of 2023 no such engine was in commercial production, although some large-scale aerospikes were in testing phases.

A reusable launch vehicle has parts that can be recovered and reflown, while carrying payloads from the surface to outer space. Rocket stages are the most common launch vehicle parts aimed for reuse. Smaller parts such as rocket engines and boosters can also be reused, though reusable spacecraft may be launched on top of an expendable launch vehicle. Reusable launch vehicles do not need to make these parts for each launch, therefore reducing its launch cost significantly. However, these benefits are diminished by the cost of recovery and refurbishment.

Rotary Rocket Company was a rocketry company that developed the Roton concept in the late 1990s as a fully reusable single-stage-to-orbit (SSTO) crewed spacecraft. The design was initially conceived by Bevin McKinney, who shared it with Gary Hudson. In 1996, Rotary Rocket Company was formed to commercialize the concept. The Roton was intended to reduce costs of launching payloads into low Earth orbit by a factor of ten.

The Lockheed Martin X-33 was a proposed uncrewed, sub-scale technology demonstrator suborbital spaceplane that was developed for a period in the 1990s. The X-33 was a technology demonstrator for the VentureStar orbital spaceplane, which was planned to be a next-generation, commercially operated reusable launch vehicle. The X-33 would flight-test a range of technologies that NASA believed it needed for single-stage-to-orbit reusable launch vehicles, such as metallic thermal protection systems, composite cryogenic fuel tanks for liquid hydrogen, the aerospike engine, autonomous (uncrewed) flight control, rapid flight turn-around times through streamlined operations, and its lifting body aerodynamics.

A solid rocket booster (SRB) is a large solid propellant motor used to provide thrust in spacecraft launches from initial launch through the first ascent. Many launch vehicles, including the Atlas V, SLS and Space Shuttle, have used SRBs to give launch vehicles much of the thrust required to place the vehicle into orbit. The Space Shuttle used two Space Shuttle SRBs, which were the largest solid propellant motors ever built and the first designed for recovery and reuse. The propellant for each solid rocket motor on the Space Shuttle weighed approximately 500,000 kilograms.

Interorbital Systems (IOS) is an American space development company based in Mojave, California. It was established in 1996 by Roderick and Randa Milliron. As of October 2023, the company is in development stage for three orbital launch vehicles: NEPTUNE, TRITON, and TRITON HEAVY.

Before the Apollo 11 Moon landing in 1969, NASA began studies of Space Shuttle designs as early as October 1968. The early studies were denoted "Phase A", and in June 1970, "Phase B", which were more detailed and specific. The primary intended use of the Phase A Space Shuttle was supporting the future space station, ferrying a minimum crew of four and about 20,000 pounds (9,100 kg) of cargo, and being able to be rapidly turned around for future flights, with larger payloads like space station modules being lifted by the Saturn V.

Romanian Cosmonautics and Aeronautics Association, also known as ARCAspace, is an aerospace company based in Râmnicu Vâlcea, Romania. It builds rockets, high-altitude balloons, and unmanned aerial vehicles. It was founded in 1999 as a non-governmental organization in Romania by the Romanian engineer and entrepreneur Dumitru Popescu and other rocket and aeronautics enthusiasts. Since then, ARCA has launched two stratospheric rockets and four large-scale stratospheric balloons including a cluster balloon. It was awarded two governmental contracts with the Romanian government and one contract with the European Space Agency. ARCASpace is currently developing several rocket systems, both orbital and suborbital, under the EcoRocket program. These vehicles include the CER rocket systems, the EcoRocket Demonstrator, Nano, 5 & Heavy, and the A1 strategic anti-ballistic interceptor. ARCA has yet to launch a vehicle above the Karman line, or sent a payload to orbit, with the majority of their projects having been abandoned due to various reasons, often including financial or regulatory constraints.

Non-rocket spacelaunch refers to theoretical concepts for launch into space where much of the speed and altitude needed to achieve orbit is provided by a propulsion technique that is not subject to the limits of the rocket equation. Although all space launches to date have been rockets, a number of alternatives to rockets have been proposed. In some systems, such as a combination launch system, skyhook, rocket sled launch, rockoon, or air launch, a portion of the total delta-v may be provided, either directly or indirectly, by using rocket propulsion.

Air-launch-to-orbit (ALTO) is the method of launching smaller rockets at altitude from a heavier conventional horizontal-takeoff aircraft, to carry satellites to low Earth orbit. It is a follow-on development of air launches of experimental aircraft that began in the late 1940s. This method, when employed for orbital payload insertion, presents significant advantages over conventional vertical rocket launches, particularly because of the reduced mass, thrust, cost of the rocket, geographical factors, and natural disasters.

StarTram is a proposed space launch system propelled by maglev technology. The initial Generation 1 facility is proposed to launch cargo only from a mountain peak at an altitude of 3 to 7 kilometres using an evacuated tube remaining at local surface level. Annual orbital lift was estimated at approximately 150,000 tons. More advanced technology is required for a Generation 2 system for passengers, with a longer track instead gradually curving up at its end to the thinner air at 22 kilometres (72,000 ft) altitude, supported by magnetic levitation, reducing g-forces when each capsule transitions from the vacuum tube to the atmosphere. A SPESIF 2010 presentation stated that Generation 1 could be completed by the year 2020 or later if funding began in 2010, and Generation 2 by 2030 or later.

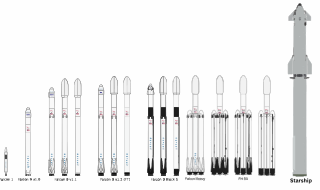

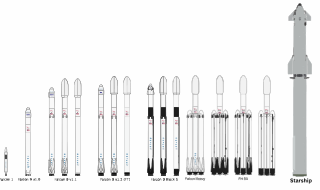

SpaceX manufactures launch vehicles to operate its launch provider services and to execute its various exploration goals. SpaceX currently manufactures and operates the Falcon 9 Block 5 family of medium-lift launch vehicles and the Falcon Heavy family of heavy-lift launch vehicles – both of which are powered by SpaceX Merlin engines and employ VTVL technologies to reuse the first stage. As of 2024, the company is also developing the fully reusable Starship launch system, which will replace the Falcon 9 and Falcon Heavy.

Falcon 9 v1.1 was the second version of SpaceX's Falcon 9 orbital launch vehicle. The rocket was developed in 2011–2013, made its maiden launch in September 2013, and its final flight in January 2016. The Falcon 9 rocket was fully designed, manufactured, and operated by SpaceX. Following the second Commercial Resupply Services (CRS) launch, the initial version Falcon 9 v1.0 was retired from use and replaced by the v1.1 version.

The Falcon 9 v1.0 was the first member of the Falcon 9 launch vehicle family, designed and manufactured by SpaceX in Hawthorne, California. Development of the medium-lift launcher began in 2005, and it first flew on June 4, 2010. The Falcon 9 v1.0 then launched four Dragon cargo spacecraft: one on an orbital test flight, then one demonstration and two operational resupply missions to the International Space Station under a Commercial Resupply Services contract with NASA.

Liquid Fly-back Booster (LFBB) was a German Aerospace Center's (DLR's) project concept to develop a liquid rocket booster capable of reuse for Ariane 1 in order to significantly reduce the high cost of space transportation and increase environmental friendliness. lrb would replace the existing liquid rocket boosters, providing main thrust during the countdown. Once separated, two winged boosters would perform an atmospheric entry, go back autonomously to the French Guiana, and land horizontally on the airport like an aeroplane.

Zero 2 Infinity is a private Spanish company developing high-altitude balloons intended to provide access to near space and low Earth orbit using a balloon-borne pod and a balloon-borne launcher.