Related Research Articles

A cotton mill is a building housing spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Trencherfield Mill is a cotton spinning mill standing next to the Leeds and Liverpool Canal in Wigan, Greater Manchester, England. It was built in 1907. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. The mill was driven by a 2,500 hp triple-expansion four-cylinder engine built by J & E Wood of Bolton in 1907. The two halves of the engine were called Rina and Helen. They drove a 26-foot flywheel with 54 ropes at 68 rpm. The engine was stopped in 1968. The mill is now part of the Wigan Pier redevelopment area and is used for other purposes.

Cedar Mill was a cotton spinning mill in the Hurst area of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1903 and 1905 for the Ashton Syndicate by Sydney Stott of Oldham. It was the last mill in Ashton spinning cotton. It ceased in 1980. It was demolished and the land was used for housing.

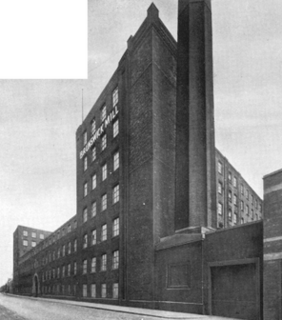

Brunswick Mill, Ancoats is a former cotton spinning mill on Bradford Road in Ancoats, Manchester, England. The mill was built around 1840, part of a group of mills built along the Ashton Canal, and at that time it was one of the country's largest mills. It was built round a quadrangle, a seven-storey block facing the canal. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967.

Coppull Mill is a former cotton spinning mill in Coppull, Chorley, Lancashire. It was opened in 1906, and its sister mill, Mavis Mill in 1908. Together they employed 700 workers. The mill was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. The building is a Grade II listed building and is now used as an enterprise centre. This was a ring mill. It was driven by a 1600 hp triple-expansion four-cylinder engine by J & E Wood built in 1906. Its 26-foot (7.9 m) flywheel operated at 68 rpm and ran 36 ropes.

Wilton Mill, Radcliffe was a cotton spinning mill in Radcliffe, Bury, Greater Manchester. It was built in 1907 and was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished, it was used by the East Lancashire Paper Company but has now been demolished leaving an empty site next to the railways and the River Irwell.

Pilot Mill, Bury is a four-storey cotton spinning mill in Bury, Greater Manchester. It was built in 1905. It was taken over by the Lancashire Cotton Corporation in 1939 and passed to Courtaulds in 1964. Production finished, it survived and as of 2010 it was in use by Antler Luggage. The Mill is currently occupied by Baum Trading Ltd and Metzuyan Ltd they have opened a retail outlet with an on site cafe.

Kingston Mill, Stockport is a mid nineteenth century cotton spinning mill in Edgeley, Stockport, Greater Manchester. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished, it was made over to multiple uses.

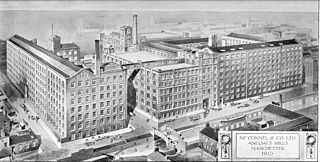

McConnel & Kennedy Mills are a group of cotton mills on Redhill Street in Ancoats, Manchester, England. With the adjoining Murrays' Mills, they form a nationally important group.

Queen Street Mill is a Grade I listed building. in Harle Syke, a suburb to the north-east of Burnley, Lancashire. It was built in 1894 for the Queen Street Manufacturing Company. It closed on 12 March 1982 and was mothballed, but was subsequently taken over by Burnley Borough Council and maintained as a museum. In the 1990s ownership passed to Lancashire Museums. Unique in being the world's only surviving operational steam-driven weaving shed, it received an Engineering Heritage Award in November 2010.

Harle Syke is a small village within the parish of Briercliffe, situated three miles north of Burnley, Lancashire, England. It was the home to eleven weaving firms, working out of seven mills. Queen Street Mill closed in 1982, and was converted to a textile museum, preserving it as a working mill. It is the world's last 19th-century steam powered weaving mill.

William Roberts and Company of Phoenix Foundry in Nelson, Lancashire, England, produced many of the steam engines that powered cotton weaving and spinning mills of Pendle and neighbouring districts. Industrial historian Mike Rothwell has called Phoenix foundry “Nelson’s most significant engineering site”.

Great Ancoats Street is a street in the inner suburb of Ancoats, Manchester, England.

Swan Lane Mills is a former cotton mill complex in Bolton, Greater Manchester. All three mills are Grade II* listed buildings. The mills were designed by Stott and Sons of Oldham. When completed, the double mill was the largest spinning mill in the world. It was granted Grade II* listed status on 26 April 1974. Number 3 Mill was separately listed as Grade II* on the same day.

References

- ↑ Ashmore 1982 , p. 212