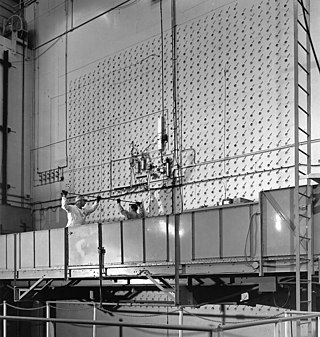

- A "bomb" (pressure vessel) containing uranium halide and sacrificial metal, probably magnesium, being lowered into a furnace

- After the reaction, remnant slag coats the interior of a bomb.

- A uranium metal "biscuit" from the reduction reaction

Related Research Articles

The Manhattan Project was a research and development program undertaken during World War II to produce the first nuclear weapons. It was led by the United States in collaboration with the United Kingdom and Canada. From 1942 to 1946, the project was directed by Major General Leslie Groves of the U.S. Army Corps of Engineers. Nuclear physicist J. Robert Oppenheimer was the director of the Los Alamos Laboratory that designed the bombs. The Army program was designated the Manhattan District, as its first headquarters were in Manhattan; the name gradually superseded the official codename, Development of Substitute Materials, for the entire project. The project absorbed its earlier British counterpart, Tube Alloys, and subsumed the program from the American civilian Office of Scientific Research and Development. The Manhattan Project employed nearly 130,000 people at its peak and cost nearly US$2 billion, over 80 percent of which was for building and operating the plants that produced the fissile material. Research and production took place at more than 30 sites across the US, the UK, and Canada.

A substance is pyrophoric if it ignites spontaneously in air at or below 54 °C (129 °F) or within 5 minutes after coming into contact with air. Examples are organolithium compounds and triethylborane. Pyrophoric materials are often water-reactive as well and will ignite when they contact water or humid air. They can be handled safely in atmospheres of argon or nitrogen. Class D fire extinguishers are designated for use in fires involving metals but not pyrophoric materials in general. A related concept is hypergolicity, in which two compounds spontaneously ignite when mixed.

Cyril Stanley Smith was a British metallurgist and historian of science. He is most famous for his work on the Manhattan Project where he was responsible for the production of fissionable metals. A graduate of the University of Birmingham and Massachusetts Institute of Technology (MIT), Smith worked for many years as a research metallurgist at the American Brass Company. During World War II he worked in the Chemical-Metallurgical Division of the Los Alamos Laboratory, where he purified, cast and shaped uranium-235 and plutonium, a metal hitherto available only in microgram amounts, and whose properties were largely unknown. After the war he served on the Atomic Energy Commission's influential General Advisory Committee, and the President's Science Advisory Committee.

Arthur Holly Compton was an American physicist who shared the 1927 Nobel Prize in Physics with C. T. R. Wilson for his discovery of the Compton effect, which demonstrated the particle nature of electromagnetic radiation. It was a sensational discovery at the time: the wave nature of light had been well-demonstrated, but the idea that light had both wave and particle properties was not easily accepted. He is also known for his leadership over the Metallurgical Laboratory at the University of Chicago during the Manhattan Project, and served as chancellor of Washington University in St. Louis from 1945 to 1953.

Chicago Pile-1 (CP-1) was the world's first artificial nuclear reactor. On 2 December 1942, the first human-made self-sustaining nuclear chain reaction was initiated in CP-1 during an experiment led by Enrico Fermi. The secret development of the reactor was the first major technical achievement for the Manhattan Project, the Allied effort to create nuclear weapons during World War II. Developed by the Metallurgical Laboratory at the University of Chicago, CP-1 was built under the west viewing stands of the original Stagg Field. Although the project's civilian and military leaders had misgivings about the possibility of a disastrous runaway reaction, they trusted Fermi's safety calculations and decided they could carry out the experiment in a densely populated area. Fermi described the reactor as "a crude pile of black bricks and wooden timbers".

Frank Harold Spedding was a Canadian-American chemist. He was a renowned expert on rare earth elements, and on extraction of metals from minerals. The uranium extraction process helped make it possible for the Manhattan Project to build the first atomic bombs.

Ames National Laboratory, formerly Ames Laboratory, is a United States Department of Energy national laboratory located in Ames, Iowa, and affiliated with Iowa State University. It is a top-level national laboratory for research on national security, energy, and the environment. The laboratory conducts research into areas of national concern, including the synthesis and study of new materials, energy resources, high-speed computer design, and environmental cleanup and restoration. It is located on the campus of Iowa State University.

The Metallurgical Laboratory was a scientific laboratory from 1942 to 1946 at the University of Chicago. It was established in February 1942 and became the Argonne National Laboratory in July 1946.

Samuel King Allison was an American physicist, most notable for his role in the Manhattan Project, for which he was awarded the Medal for Merit. A professor who studied X-rays, he was director of the Metallurgical Laboratory from 1943 until 1944, and later worked at the Los Alamos Laboratory — where he "rode herd" on the final stages of the project as part of the "Cowpuncher Committee", and read the countdown for the detonation of the Trinity nuclear test. After the war, he returned to the University of Chicago to direct the Institute for Nuclear Studies and was involved in the "scientists' movement", lobbying for civilian control of nuclear weapons.

The Manhattan Project was a research and development project that produced the first atomic bombs during World War II. It was led by the United States with the support of the United Kingdom and Canada. From 1942 to 1946, the project was under the direction of Major General Leslie Groves of the US Army Corps of Engineers. The Army component of the project was designated the Manhattan District; "Manhattan" gradually became the codename for the entire project. Along the way, the project absorbed its earlier British counterpart, Tube Alloys. The Manhattan Project began modestly in 1939, but grew to employ more than 130,000 people and cost nearly US$2 billion. Over 90% of the cost was for building factories and producing the fissionable materials, with less than 10% for development and production of the weapons.

The X-10 Graphite Reactor is a decommissioned nuclear reactor at Oak Ridge National Laboratory in Oak Ridge, Tennessee. Formerly known as the Clinton Pile and X-10 Pile, it was the world's second artificial nuclear reactor and the first intended for continuous operation. It was built during World War II as part of the Manhattan Project.

Joseph William Kennedy was an American chemist who co-discovered plutonium, along with Glenn T. Seaborg, Edwin McMillan, and Arthur Wahl. During World War II, he led the CM Division at the Manhattan Project's Los Alamos Laboratory, where he oversaw research onto the chemistry and metallurgy of uranium and plutonium. After the war, he was recruited as a professor at Washington University in St. Louis, where he is credited with transforming a university primarily concerned with undergraduate teaching into one that also boasts strong graduate and research programs. He died of cancer of the stomach at the age of 40.

Charles Allen Thomas was a noted American chemist and businessman, and an important figure in the Manhattan Project. He held over 100 patents.

The Ames process is a process by which pure uranium metal is obtained. It can be achieved by mixing any of the uranium halides with magnesium metal powder or aluminium metal powder.

The Montreal Laboratory was a program established by the National Research Council of Canada during World War II to undertake nuclear research in collaboration with the United Kingdom, and to absorb some of the scientists and work of the Tube Alloys nuclear project in Britain. It became part of the Manhattan Project, and designed and built some of the world's first nuclear reactors.

The bismuth-phosphate process was used to extract plutonium from irradiated uranium taken from nuclear reactors. It was developed during World War II by Stanley G. Thompson, a chemist working for the Manhattan Project at the University of California, Berkeley. This process was used to produce plutonium at the Hanford Site. Plutonium was used in the atomic bomb that was used in the atomic bombing of Nagasaki in August 1945. The process was superseded in the 1950s by the REDOX and PUREX processes.

The Westinghouse Lamp Plant located in Bloomfield, New Jersey, was one of the lamp manufacturing plants of Westinghouse Electric Corporation. The plant had a major involvement in supplying uranium metal for the world's first self-sustaining chain reaction in Chicago in the early phase of the Manhattan Project to create the first atomic bomb.

Edward Creutz was an American physicist who worked on the Manhattan Project at the Metallurgical Laboratory and the Los Alamos Laboratory during World War II. After the war he became a professor of physics at the Carnegie Institute of Technology. He was Vice President of Research at General Atomics from 1955 to 1970. He published over 65 papers on botany, physics, mathematics, metallurgy and science policy, and held 18 patents relating to nuclear energy.

Harley A. Wilhelm was an American chemist who helped to establish the United States Department of Energy's Ames Laboratory at Iowa State University. His uranium extraction process helped make it possible for the Manhattan Project to build the first atomic bombs.

The Los Alamos Laboratory, also known as Project Y, was a secret scientific laboratory established by the Manhattan Project and overseen by the University of California during World War II. It was operated in partnership with the United States Army. Its mission was to design and build the first atomic bombs. J. Robert Oppenheimer was its first director, serving from 1943 to December 1945, when he was succeeded by Norris Bradbury. In order to enable scientists to freely discuss their work while preserving security, the laboratory was located on the isolated Pajarito Plateau in Northern New Mexico. The wartime laboratory occupied buildings that had once been part of the Los Alamos Ranch School.

References

- Alexander, Peter P. (1943). The Production of Uranium Metal by Metal Hydrides Incorporated. Washington, D.C.: United States Atomic Energy Commission. doi:10.2172/4357577. OSTI 4357577.

- Alexander, Peter P. (October 1938). "The Hydride Process - IV. Commercial Production of Uranium". Metals & Alloys. 9: 270–274. ISSN 0025-5319.

- Anderson, Herbert L. (1975). "Assisting Fermi". In Wilson, Jane (ed.). All In Our Time: The Reminiscences of Twelve Nuclear Pioneers. Chicago: Bulletin of the Atomic Scientists. pp. 66–104. OCLC 1982052.

- Compton, Arthur (1956). Atomic Quest . New York: Oxford University Press. OCLC 173307.

- Corbett, John D. (2001). Frank Harold Spedding 1902–1982. Vol. 80. National Academy of Sciences. ISBN 978-0-309-08281-5 . Retrieved 6 June 2015.

{{cite book}}:|journal=ignored (help) - Driggs, F. H.; Lilliendahl, W. C. (1930). "Preparation of Metal Powders by Electrolysis of Fused Salts — Ductile Uranium". Industrial & Engineering Chemistry. 22 (5): 516–519. doi:10.1021/ie50245a025. ISSN 0096-4484.

the melting point for two samples were 1690 °C and 1688°C

- Goldman, Joanne Abel (July 2000). "National Science in the Nation's Heartland: The Ames Laboratory and Iowa State University, 1942–1965". Technology and Culture . 41 (3): 435–459. doi: 10.1353/tech.2000.0100 . ISSN 0040-165X. JSTOR 25147537. S2CID 109626578 . Retrieved 29 May 2016.

- Goldman, Joanne Abel (Winter 2008). "Frank Spedding and the Ames Laboratory: The Development of a Science Manager". The Annals of Iowa . 67 (1): 51–81. doi: 10.17077/0003-4827.1169 . ISSN 0003-4827.

- Hewlett, Richard G.; Anderson, Oscar E. (1962). The New World, 1939–1946 (PDF). University Park: Pennsylvania State University Press. ISBN 978-0-520-07186-5. OCLC 637004643 . Retrieved 26 March 2013.

- Hole, W. L.; Wright, R. W. (1939). "Emissive and Thermionic Characteristics of Uranium". Physical Review . 56 (8): 785–787. Bibcode:1939PhRv...56..785H. doi:10.1103/PhysRev.56.785.

for melting point, 1700±25°C

- Katz, J. J.; Rabinowitch, Eugene (1951). The Chemistry of Uranium. Vol. Part 1: The Element, its Binary and Related Compounds. New York: McGraw-Hill. ISBN 978-5-88135-966-9. OCLC 559738.

- Jones, Vincent (1985). Manhattan: The Army and the Atomic Bomb (PDF). Washington, D.C.: United States Army Center of Military History. OCLC 10913875. Archived from the original (PDF) on 7 October 2014. Retrieved 25 August 2013.

- Manhattan District (1947). Manhattan District History, Book I, Volume 4, Chapter 11 – Ames Project (PDF). Washington, D.C.

{{cite book}}: CS1 maint: location missing publisher (link) - Moore, Mike (July 1994). "Lying well". Bulletin of the Atomic Scientists . 50 (4): 2. Bibcode:1994BuAtS..50d...2M. doi:10.1080/00963402.1994.11456528 . Retrieved 4 June 2016.

- Payne, Carolyn Stilts (1992). The Ames Project: Administering Classified Research as a Part of the Manhattan Project at Iowa State College, 1942–1945 (PhD thesis). Iowa State University. Paper 10338. Retrieved 29 May 2016.

- Rhodes, Richard (1986). The Making of the Atomic Bomb. London: Simon & Schuster. ISBN 978-0-671-44133-3.

- Wilhelm, Harley A.; Carlson, O. Norman (1950). The Uranium-Manganese and Uranium-Copper Alloy Systems. Oak Ridge, Tennessee: U.S. Atomic Energy Commission, Technical Information Division. Retrieved 4 February 2017.