Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics.

A printed circuit board (PCB), also called printed wiring board (PWB), is a medium used to connect or "wire" components to one another in a circuit. It takes the form of a laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with a pattern of traces, planes and other features etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers, generally by means of soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds vias, drilled holes that allow electrical interconnections between conductive layers.

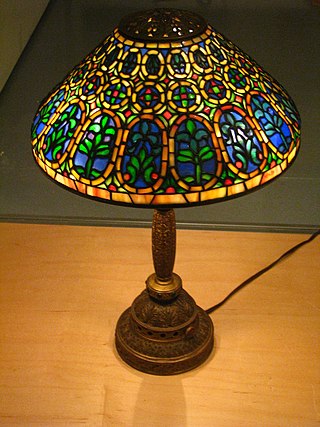

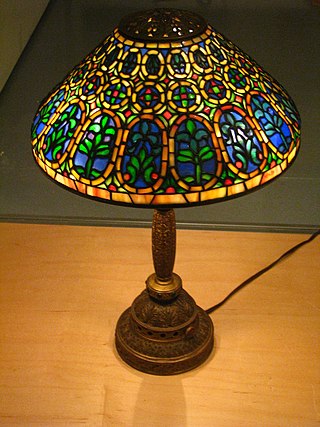

Stained glass is coloured glass as a material or works created from it. Although traditionally made in flat panels and used as windows, the creations of modern stained glass artists also include three-dimensional structures and sculpture. Modern vernacular usage has often extended the term "stained glass" to include domestic lead light and objets d'art created from foil glasswork exemplified in the famous lamps of Louis Comfort Tiffany.

Art glass is a subset of glass art, this latter covering the whole range of art made from glass. Art glass normally refers only to pieces made since the mid-19th century, and typically to those purely made as sculpture or decorative art, with no main utilitarian function, such as serving as a drinking vessel, though of course stained glass keeps the weather out, and bowls may still be useful.

Studio glass is the modern use of glass as an artistic medium to produce sculptures or three-dimensional artworks in the fine arts. The glass objects created are intended to make a sculptural or decorative statement, and typically serve no useful function. Though usage varies, the term is properly restricted to glass made as art in small workshops, typically with the personal involvement of the artist who designed the piece. This is in contrast to art glass, made by craftsmen in factories, and glass art, covering the whole range of glass with artistic interest made throughout history. Both art glass and studio glass originate in the 19th century, and the terms compare with studio pottery and art pottery, but in glass the term "studio glass" is mostly used for work made in the period beginning in the 1960s with a major revival in interest in artistic glassmaking.

Beveled glass is usually made by taking thick glass and creating an angled surface cut (bevel) around the entire periphery. Bevels act as prisms in sunlight creating an interesting color refraction which both highlights the glass work and provides a spectrum of colors which would ordinarily be absent in clear float glass.

Cloisonné is an ancient technique for decorating metalwork objects with colored material held in place or separated by metal strips or wire, normally of gold. In recent centuries, vitreous enamel has been used, but inlays of cut gemstones, glass and other materials were also used during older periods; indeed cloisonné enamel very probably began as an easier imitation of cloisonné work using gems. The resulting objects can also be called cloisonné. The decoration is formed by first adding compartments to the metal object by soldering or affixing silver or gold as wires or thin strips placed on their edges. These remain visible in the finished piece, separating the different compartments of the enamel or inlays, which are often of several colors. Cloisonné enamel objects are worked on with enamel powder made into a paste, which then needs to be fired in a kiln. If gemstones or colored glass are used, the pieces need to be cut or ground into the shape of each cloison.

A came is a divider bar used between small pieces of glass to make a larger glazing panel.

Leaded glass may refer to:

A Tiffany lamp is a type of lamp made of glass and shade designed by Louis Comfort Tiffany or artisans, mostly women, and made in his design studio. The glass in the lampshades is put together with the copper-foil technique instead of leaded, the classic technique for stained-glass windows. Tiffany lamps are considered part of the Art Nouveau movement. Considerable numbers of designs were produced from 1893 onwards.

Flashing refers to thin pieces of impervious material installed to prevent the passage of water into a structure from a joint or as part of a weather resistant barrier system. In modern buildings, flashing is intended to decrease water penetration at objects such as chimneys, vent pipes, walls, windows and door openings to make buildings more durable and to reduce indoor mold problems. Metal flashing materials include lead, aluminium, copper, stainless steel, zinc alloy, and other materials.

Leadlights, leaded lights or leaded windows are decorative windows made of small sections of glass supported in lead cames. The technique of creating windows using glass and lead came to be known as came glasswork. The term 'leadlight' could be used to describe any window in which the glass is supported by lead, but traditionally, a distinction is made between stained glass windows and leadlights; the former is associated with the ornate coloured-glass windows of churches and similar buildings, while the latter is associated with the windows of vernacular architecture and defined by its simplicity.

Breaker-grozier pliers, or groziers, are pliers used by glaziers to break and finish glass in a controlled manner, a technique known as grozing. They are dual purpose pliers, with a flat jaw that is used for breaking out scores and a curved jaw that is used for grozing flares from the edge of broken glass. Both jaws are serrated for removing flares and tiny points of glass.

Metals used for architectural purposes include lead, for water pipes, roofing, and windows; tin, formed into tinplate; zinc, copper and aluminium, in a range of applications including roofing and decoration; and iron, which has structural and other uses in the form of cast iron or wrought iron, or made into steel. Metal alloys used in building include bronze ; brass ; monel metal and nickel silver, mainly consisting of nickel and copper; and stainless steel, with important components of nickel and chromium.

Stained glass conservation refers to the protection and preservation of historic stained glass for present and future generations. It involves any and all actions devoted to the prevention, mitigation, or reversal of the processes of deterioration that affect such glassworks and subsequently inhibit individuals' ability to access and appreciate them, as part of the world's collective cultural heritage. It functions as a part of the larger practices of cultural heritage conservation (conservation-restoration) and architectural conservation.

Medieval stained glass is the coloured and painted glass of medieval Europe from the 10th century to the 16th century. For much of this period stained glass windows were the major pictorial art form, particularly in northern France, Germany and England, where windows tended to be larger than in southern Europe. In some countries, such as Sweden and England, only a small number of original stained windows has survived to this day.

Soldering is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint.

Stained glass refers to both coloured glass as a material and to works made from it.

Carl Huneke was a German-American stained glass artist and master craftsman.

Belcher mosaic windows were manufactured in the United States by the Belcher Mosaic Glass Company between 1884 and 1897. Identifiable by their unique, continuous lead matrix and use of small, glass tesserae, Belcher windows are an example of the innovation occurring in decorative glass during the nineteenth century. Also referred to as “mercury mosaics” or “metallo mosaics”, Belcher windows echo many of the larger concepts at play in American architecture during the end of the 1800s including an emphasis on the inherent nature of the material to impart design and a capitalization of developments in technology to create more affordable decorative objects. While their era of production was short lived, Belcher windows were popular and many examples still survive today, both in situ but more likely in collections.