Reinforced concrete, also called ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars (rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion.

Fiberglass or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Rebar, known when massed as reinforcing steel or steel reinforcement, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

In mechanics, compressive strength is the capacity of a material or structure to withstand loads tending to reduce size. In other words, compressive strength resists compression, whereas tensile strength resists tension. In the study of strength of materials, tensile strength, compressive strength, and shear strength can be analyzed independently.

Eugène Freyssinet was a French structural and civil engineer. He was the major pioneer of prestressed concrete.

Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" (compressed) during production, in a manner that strengthens it against tensile forces which will exist when in service.

A expansion joint, or movement joint, is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of building materials. They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

This is an alphabetical list of articles pertaining specifically to structural engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of engineers.

Fritz Leonhardt was a German structural engineer who made major contributions to 20th-century bridge engineering, especially in the development of cable-stayed bridges. His book Bridges: Aesthetics and Design is well known throughout the bridge engineering community.

The history of structural engineering dates back to at least 2700 BC when the step pyramid for Pharaoh Djoser was built by Imhotep, the first architect in history known by name. Pyramids were the most common major structures built by ancient civilizations because it is a structural form which is inherently stable and can be almost infinitely scaled.

Cellular confinement systems (CCS)—also known as geocells—are widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention. Typical cellular confinement systems are geosynthetics made with ultrasonically welded high-density polyethylene (HDPE) strips or novel polymeric alloy (NPA)—and expanded on-site to form a honeycomb-like structure—and filled with sand, soil, rock, gravel or concrete.

Structural engineering depends on the knowledge of materials and their properties, in order to understand how different materials resist and support loads.

In the Eurocode series of European standards (EN) related to construction, Eurocode 2: Design of concrete structures specifies technical rules for the design of concrete, reinforced concrete and prestressed concrete structures, using the limit state design philosophy. It was approved by the European Committee for Standardization (CEN) on 16 April 2004 to enable designers across Europe to practice in any country that adopts the code.

Concrete has relatively high compressive strength, but significantly lower tensile strength. The compressive strength is typically controlled with the ratio of water to cement when forming the concrete, and tensile strength is increased by additives, typically steel, to create reinforced concrete. In other words we can say concrete is made up of sand, ballast, cement and water.

A cover meter is an instrument to locate rebars and measure the exact concrete cover. Rebar detectors are less sophisticated devices that can only locate metallic objects below the surface. Due to the cost-effective design, the pulse-induction method is one of the most commonly used solutions.

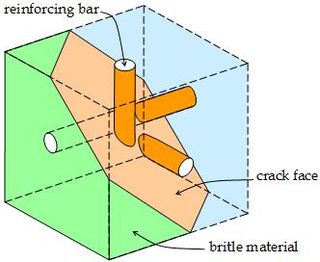

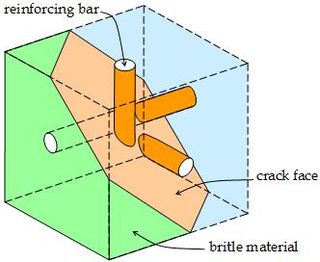

In solid mechanics, a reinforced solid is a brittle material that is reinforced by ductile bars or fibres. A common application is reinforced concrete. When the concrete cracks the tensile force in a crack is not carried any more by the concrete but by the steel reinforcing bars only. The reinforced concrete will continue to carry the load provided that sufficient reinforcement is present. A typical design problem is to find the smallest amount of reinforcement that can carry the stresses on a small cube. This can be formulated as an optimization problem.

Gustaaf Paul Robert Magnel was a Belgian engineer and professor at Ghent University, known for his expertise regarding reinforced concrete and prestressed concrete.

Franz-Josef Ulm is a structural engineer, an engineering scientist and a professor since 1999. He is Professor of Civil & Environmental Engineering at the Massachusetts Institute of Technology (MIT), the Faculty Director of the Concrete Sustainability Hub (CSHub@MIT). He is credited for discovering the nanogranular structure of Calcium-Silicate-Hydrates (C-S-H), the binding phase of concrete, and for the development of concepts of nanoengineering of concrete which combine advanced nanomechanics experiments with molecular simulation results. He speaks up for an environmental sustainable engineering, with "greener" concrete with lower CO2 footprint, to reduce the carbon footprint of concrete; to enhance concrete's resilience; and reduce its impact on global warming.

The Neoloy Geocell is a Cellular Confinement System (geocell) developed and manufactured by PRS Geo-Technologies Ltd. Geocells are extruded in ultrasonically welded strips. The folded strips are opened on-site to form a 3D honeycomb matrix, which is then filled with granular material. The 3D confinement system is used to stabilize soft subgrade soil and reinforce the subbase and base layers in flexible pavements. Cellular confinement is also used for soil protection and erosion control for slopes, including channels, retention walls, reservoirs and landfills.

Tensioned stone is a high-performance composite construction material: stone held in compression with tension elements. The tension elements can be connected to the outside of the stone, but more typically uses tendons threaded internally through a duct formed from aligned drilled holes.