A floor is the bottom surface of a room or vehicle. Floors vary from simple dirt in a cave to many layered surfaces made with modern technology. Floors may be stone, wood, bamboo, metal or any other material that can support the expected load.

Flooring is the general term for a permanent covering of a floor, or for the work of installing such a floor covering. Floor covering is a term to generically describe any finish material applied over a floor structure to provide a walking surface. Both terms are used interchangeably but floor covering refers more to loose-laid materials.

A dipstick is one of several measurement devices.

Vinyl composition tile (VCT) is a finished flooring material used primarily in commercial and institutional applications. Modern vinyl floor tiles and sheet flooring and versions of those products sold since the early 1980s are composed of colored polyvinyl chloride (PVC) chips formed into solid sheets of varying thicknesses by heat and pressure. Floor tiles are cut into modular shapes such 12-by-12-inch squares or 12-by-24-inch rectangles. In installation the floor tiles or sheet flooring are applied to a smooth, leveled sub-floor using a specially formulated vinyl adhesive or tile mastic that remains pliable. In commercial applications some tiles are typically waxed and buffed using special materials and equipment.

Hardenability is the depth to which a steel is hardened after putting it through a heat treatment process. It should not be confused with hardness, which is a measure of a sample's resistance to indentation or scratching. It is an important property for welding, since it is inversely proportional to weldability, that is, the ease of welding a material.

Water content or moisture content is the quantity of water contained in a material, such as soil, rock, ceramics, crops, or wood. Water content is used in a wide range of scientific and technical areas, and is expressed as a ratio, which can range from 0 to the value of the materials' porosity at saturation. It can be given on a volumetric or mass (gravimetric) basis.

Waterproofing is the process of making an object, person or structure waterproof or water-resistant so that it remains relatively unaffected by water or resisting the ingress of water under specified conditions. Such items may be used in wet environments or underwater to specified depths.

Moisture vapor transmission rate (MVTR), also water vapor transmission rate (WVTR), is a measure of the passage of water vapor through a substance. It is a measure of the permeability for vapor barriers.

Coal analysis techniques are specific analytical methods designed to measure the particular physical and chemical properties of coals. These methods are used primarily to determine the suitability of coal for coking, power generation or for iron ore smelting in the manufacture of steel.

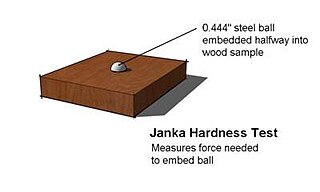

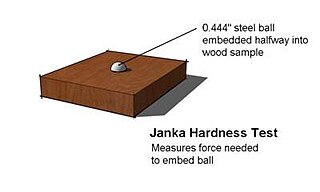

The Janka hardness test, created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. It measures the force required to embed an 11.28-millimeter-diameter steel ball halfway into a sample of wood.

Radon mitigation is any process used to reduce radon gas concentrations in the breathing zones of occupied buildings, or radon from water supplies. Radon is a significant contributor to environmental radioactivity and indoor air pollution. Exposure to radon can cause serious health problems such as lung cancer.

A Schmidt hammer, also known as a Swiss hammer or a rebound hammer or concrete hammer test, is a device to measure the elastic properties or strength of concrete or rock, mainly surface hardness and penetration resistance. It was invented by Ernst Heinrich Wilhelm Schmidt, a Swiss engineer.

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods.

Geotechnical investigations are performed by geotechnical engineers or engineering geologists to obtain information on the physical properties of soil earthworks and foundations for proposed structures and for repair of distress to earthworks and structures caused by subsurface conditions; this type of investigation is called a site investigation. Geotechnical investigations are also used to measure the thermal resistance of soils or backfill materials required for underground transmission lines, oil and gas pipelines, radioactive waste disposal, and solar thermal storage facilities. A geotechnical investigation will include surface exploration and subsurface exploration of a site. Sometimes, geophysical methods are used to obtain data about sites. Subsurface exploration usually involves soil sampling and laboratory tests of the soil samples retrieved.

Indoor mold or indoor mould, also sometimes referred to as mildew, is a fungal growth that develops on wet materials in interior spaces. Mold is a natural part of the environment and plays an important part in nature by breaking down dead organic matter such as fallen leaves and dead trees; indoors, mold growth should be avoided. Mold reproduces by means of tiny spores. The spores are like seeds, but invisible to the naked eye, that float through the air and deposit on surfaces. When the temperature, moisture, and available nutrient conditions are correct, the spores can form into new mold colonies where they are deposited. There are many types of mold, but all require moisture and a food source for growth.

Nuclear densitometry is a technique used in civil construction and the petroleum industry, as well as for mining and archaeology purposes, to measure the density and inner structure of the test material. The processes uses a nuclear density gauge, which consists of a radiation source that emits particles and a sensor that counts the received particles that are either reflected by the test material or pass through it. By calculating the percentage of particles that return to the sensor, the gauge can be calibrated to measure the density.

Moisture meters are measuring instruments used to measure the percentage of water in a given substance, as physical properties are strongly affected by moisture content and high moisture content for a period of time may progressively degrade a material. Meters exist for various substances, including wood, building materials, concrete, and soil.

The container compression test measures the compressive strength of packages such as boxes, drums, and cans. It usually provides a plot of deformation vs compressive force.

Epoxy moisture control systems are chemical barriers that are used to prevent moisture damage to flooring. Excessive moisture vapor emissions in concrete slabs can mean significant, expensive damage to a flooring installation. Hundreds of millions of dollars are spent annually just in the United States to correct moisture-related problems in flooring. These problems include failure of the flooring adhesive; damage to the floor covering itself, such as blistering; the formation of efflorescence salts; and the growth of mold and mildew.

Floor slip resistance testing is the science of measuring the coefficient of friction of flooring surfaces, either in a laboratory or on floors in situ. Slip resistance testing is usually desired by the building's owner or manager when there has been a report of a slip and fall accident, when there has been a report of a near accident, or (preferably) before the flooring is installed on the property. Flooring is tested using a tribometer to discover if there is a high propensity for slip and fall accidents on it, either dry and/or when wet with water or lubricated with other contaminants such as kitchen grease, hydraulic oil, etc. There have been numerous floor slip resistance testing tribometers and lab devices produced around the world to measure both the static (stationary) and dynamic coefficient of friction, but presently there are only a few that have been proven to be reliable for obtaining useful safety results and that have current official test methods. Static coefficient of friction (SCOF) testing has always been unreliable for assessing safety in the wet condition, so any reliable slip resistance test will be measuring the available slip resistance to someone who is moving (dynamic) across the floor, and therefore will be assessing dynamic coefficient of friction (DCOF). If an instrument has no official published test method, or has a withdrawn test method, then there is a problem with the instrument, often being poor precision.