A head saw, framesaw, gang saw or head rig is the saw that makes the initial cuts in a log at a sawmill, turning a log into cants, or planks of wood.

A head saw, framesaw, gang saw or head rig is the saw that makes the initial cuts in a log at a sawmill, turning a log into cants, or planks of wood.

The original powered head saw was composed of long, narrow blades that used an up-and-down motion, a reciprocating saw. Each blade was set at a fixed width meaning each log was cut identically, regardless of flaws. This design was not energy efficient and around 1860 sawmills began to adopt the more efficient circular saw. In the 1870s, the limitation of log size due to the radius of the circular saw was improved with the introduction of the double circular saw- with one blade atop the other. In the 1880s, the band saw was introduced and was able to allow the head saw to handle logs of nearly unlimited size, ideal for the Californian redwoods. [1]

Today, head saws are mostly used for cutting logs 16 to 72 inches (0.41 to 1.83 m) in diameter depending upon the type of band mill the saws are mounted on. More optimized machines now cut the smaller diameters since they are far more efficient and can provide greater production.

Dependent upon the log diameter, head saws can cut a log at speeds ranging from 1 to 300 feet per minute (0.30 to 91.44 m/min). Generally, log carriage speeds are adjustable for optimal performance.

A head saw is operated by a head sawyer. The sawyer positions the log to the proper position for the initial cut while sizing up the log determining optimal usage. The offbearer is responsible for removing the cut boards. [2]

A circular saw is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power source. An abrasive saw has a powered circular blade designed to cut through metal or ceramic.

A chainsaw is a portable gasoline-, electric-, or battery-powered saw that cuts with a set of teeth attached to a rotating chain driven along a guide bar. It is used in activities such as tree felling, limbing, bucking, pruning, cutting firebreaks in wildland fire suppression, and harvesting of firewood. Chainsaws with specially designed bar-and-chain combinations have been developed as tools for use in chainsaw art and chainsaw mills. Specialized chainsaws are used for cutting concrete during construction developments. Chainsaws are sometimes used for cutting ice; for example, ice sculpture and winter swimming in Finland.

Portable sawmills are sawmills small enough to be moved easily and set up in the field. They have existed for over 100 years but grew in popularity in the United States starting in the 1970s, when the 1973 oil crisis and the back-to-the-land movement had led to renewed interest in small woodlots and in self-sufficiency. Their popularity has grown exponentially since 1982, when the portable bandsaw mill was first commercialized.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut.

In woodworking, a rip-cut is a type of cut that severs or divides a piece of wood parallel to the grain. The other typical type of cut is a cross-cut, a cut perpendicular to the grain. Unlike cross-cutting, which shears the wood fibers, a rip saw works more like a series of chisels, lifting off small splinters of wood. The nature of the wood grain requires the shape of the saw teeth to be different thus the need for both rip saws and crosscut saws; however some circular saw blades are combination blades and can make both types of cuts. A rip cut is the fundamental type of cut made at a sawmill.

A sawmill or lumber mill is a facility where logs are cut into lumber. Modern sawmills use a motorized saw to cut logs lengthwise to make long pieces, and crosswise to length depending on standard or custom sizes. The "portable" sawmill is of simple operation. The log lies flat on a steel bed, and the motorized saw cuts the log horizontally along the length of the bed, by the operator manually pushing the saw. The most basic kind of sawmill consists of a chainsaw and a customized jig, with similar horizontal operation.

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

A biscuit joiner or biscuit jointer is a woodworking tool used to join two pieces of wood together. A biscuit joiner uses a small circular saw blade to cut a crescent-shaped hole in the opposite edges of two pieces of wood or wood composite panels. An oval-shaped, highly dried and compressed wooden biscuit is covered with glue, or glue is applied in the slot. The biscuit is immediately placed in the slot, and the two boards are clamped together. The wet glue expands the biscuit, further improving the bond.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations. They remove material by their movement within the machine or directly from the cutter's shape.

Wood shingles are thin, tapered pieces of wood primarily used to cover roofs and walls of buildings to protect them from the weather. Historically shingles were split from straight grained, knot free bolts of wood. Today shingles are mostly made by being cut which distinguishes them from shakes, which are made by being split out of a bolt.

Bucking is the process of cutting a felled and delimbed tree into logs. Significant value can be lost by sub-optimal bucking because logs destined for plywood, lumber, and pulp each have their own value and specifications for length, diameter, and defects. Cutting from the top down is overbucking and from the bottom up is underbucking.

A saw pit or sawpit is a pit over which lumber is positioned to be sawed with a long two-handled saw by two people, one standing above the timber and the other below. It was used for producing sawn planks from tree trunks, which could then be cut down into boards, pales, posts, etc. Many towns, villages and country estates had their own saw pits. The greatest user of sawn timber in past centuries was the shipbuilding industry.

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths,, onto one bobbin.

A chainsaw mill or PortaMill or Alaskan mill or Alaskan sawmill or Logosol sawmill is a type of sawmill incorporating a chainsaw, that is used by one or two operators to mill logs into lumber for use in furniture, construction and other uses.

A firewood processor is a machine designed to cut and split firewood with minimal manual handling of the logs. There are typically four main parts of the machine, each dedicated to a separate function. Processing begins with a log pile – a pile of logs that have been de-limbed and cut to an appropriate length, generally 10–12 feet (3.0–3.7 m). Popular brands include Multitek, Wood Beaver, DYNA, Hakki Pilke, and Blockbuster. Many individuals use processors commercially and also privately as a hobby. Others choose to rent them as an alternative to purchasing.

Carbide saws are machine tools for cutting. The saw teeth are made of cemented carbide, so that hard materials can be cut.

A swingblade sawmill utilizes a single circular sawblade which pivots about a 90 degree point, to saw in both vertical and horizontal planes. The single blade travels horizontally in one direction down the log, and returns in vertical position, thus removing a sawn piece of timber. The swingblade head unit is normally mounted on a moving frame that travels along a track or tracks, up and down a stationary log.

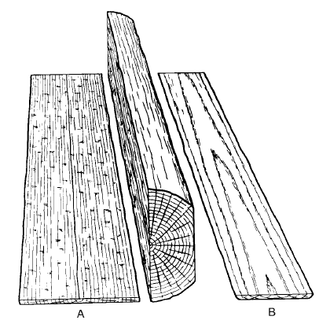

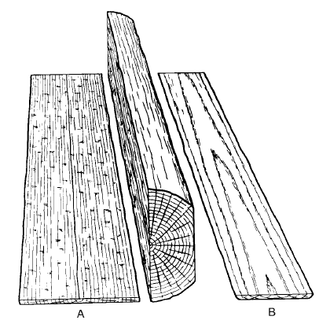

Flat sawing, flitch sawing or plain sawing is a woodworking process that produces flat cut or plain cut boards of lumber.