Computer-aided design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) is also used.

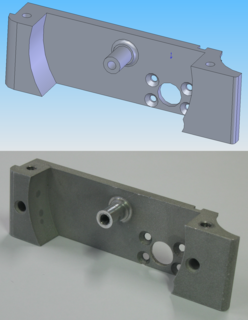

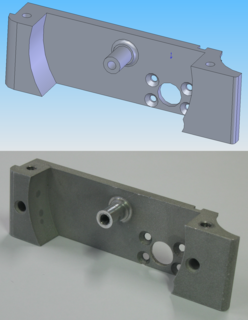

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools and related ones in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside computer-aided design (CAD) to create objects.

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes finite element analysis (FEA), computational fluid dynamics (CFD), multibody dynamics (MBD), durability and optimization. It is included with computer-aided design (CAD) and computer-aided manufacturing (CAM) in the collective abbreviation "CAx".

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprises.

Computer-aided technologies (CAx) is the use of computer technology to aid in the design, analysis, and manufacture of products.

Manufacturingresource planning is defined as a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control entire production precess. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as flexible design and manufacturing.

Computer-aided production engineering (CAPE) is a relatively new and significant branch of engineering. Global manufacturing has changed the environment in which goods are produced. Meanwhile, the rapid development of electronics and communication technologies has required design and manufacturing to keep pace.

Product engineering refers to the process of designing and developing a device, assembly, or system such that it be produced as an item for sale through some product manufacturing process. Product engineering usually entails activity dealing with issues of cost, producibility, quality, performance, reliability, serviceability, intended lifespan and user features. These product characteristics are generally all sought in the attempt to make the resulting product attractive to its intended market and a successful contributor to the business of the organization that intends to offer the product to that market. It includes design, development and transitioning to manufacturing of the product. The term encompasses developing the concept of the product and the design and development of its mechanical, electronics and software components. After the initial design and development is done, transitioning the product to manufacture it in volumes is considered part of product engineering.

Virtual engineering (VE) is defined as integrating geometric models and related engineering tools such as analysis, simulation, optimization, and decision making tools, etc., within a computer-generated environment that facilitates multidisciplinary collaborative product development. Virtual engineering shares many characteristics with software engineering, such as the ability to obtain many different results through different implementations.

ISO 13399 is an international technical standard by ISO for the computer-interpretable representation and exchange of industrial product data about cutting tools and toolholders. The objective is to provide a mechanism capable of describing product data regarding cutting tools, independent from any particular system. The nature of this description makes it suitable not only for neutral file exchange, but also as a basis for implementing and sharing product databases and archiving, regarding cutting tools.

Manufacturing engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238.

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimized to improve production output. MES works in real time to enable the control of multiple elements of the production process.

WorkPLAN is a range of Enterprise Resource Planning (ERP) software products developed by Sescoi for custom manufacturers or departments who work project-based and need specialized ERP software for project management.

The following outline is provided as an overview of and topical guide to production:

Tool management is needed in metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. Tool data management consists of specific data fields, graphics and parameters that are essential in production, as opposed to managing general production equipment.

Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas: Mechanical engineering, industrial engineering, and management science.

EXAPT is a production oriented programming language to generate NC programs with control information for machining tools and enables to consider production-related issues of various machining processes.