This article relies largely or entirely on a single source .(January 2021) |

1350 aluminium alloy is nearly pure aluminium consist of minimum of weight percentage of 99.5% of Aluminium. [1]

This article relies largely or entirely on a single source .(January 2021) |

1350 aluminium alloy is nearly pure aluminium consist of minimum of weight percentage of 99.5% of Aluminium. [1]

| Element [1] | Content (%) |

|---|---|

| Aluminium | 99.50 (min) |

| Properties [1] | Metric |

|---|---|

| Density | 2.6-2.8 g/cm3 |

| Elastic modulus | 70-80 GPa |

| Poisson's ratio | 0.33 |

| Thermal conductivity | 230 (W/mK) |

| ASTM B230 | ASTM B231 | ASTM B232 | ASTM B233 | ASTM B236 |

| ASTM B314 | ASTM B323 | ASTM B324 | ASTM B400 | ASTM B401 |

| ASTM B524 | ASTM B549 | ASTM B609 | SAE J454 (EC-O) |

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength.

Duralumin is a trade name for one of the earliest types of age-hardenable aluminium–copper alloys. The term is a combination of Dürener and aluminium. Its use as a trade name is obsolete. Today the term mainly refers to aluminium-copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 and 2024 alloys used in airframe fabrication.

Aluminium bronze is a type of bronze in which aluminium is the main alloying metal added to copper, in contrast to standard bronze or brass. A variety of aluminium bronzes of differing compositions have found industrial use, with most ranging from 5% to 11% aluminium by weight, the remaining mass being copper; other alloying agents such as iron, nickel, manganese, and silicon are also sometimes added to aluminium bronzes.

Aluminum building wiring is a type of electrical wiring for residential construction or houses that uses aluminum electrical conductors. Aluminum provides a better conductivity-to-weight ratio than copper, and therefore is also used for wiring power grids, including overhead power transmission lines and local power distribution lines, as well as for power wiring of some airplanes. Utility companies have used aluminum wire for electrical transmission in power grids since around the late 1800s to the early 1900s. It has cost and weight advantages over copper wires. Aluminum in power transmission and distribution applications is still the preferred wire material today.

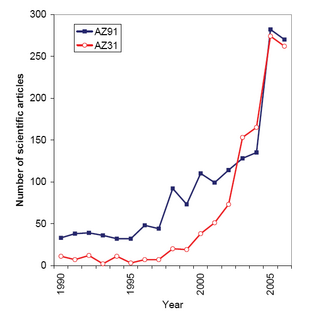

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Aluminium recycling is the process in which secondary commercial aluminium is created from scrap or other forms of end-of-life or otherwise unusable aluminium. It involves re-melting the metal, which is cheaper and more energy-efficient than the production of virgin aluminium by electrolysis of alumina (Al2O3) refined from raw bauxite by use of the Bayer and Hall–Héroult processes.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Bharat Aluminium Company Ltd. (BALCO) was an Indian government owned aluminium producer under Ministry of Mines, Government of India. In 2000, the Ministry of Mines, Government of India sold it to Vedanta Resources when Atal Bihari Vajpayee-Bharatiya Janta Party-National Democratic Alliance-led-government was in power. BALCO was incorporated in the year 1965 as a central public sector unit (CPSU) and it was the central government-establishment until 2001, when it was taken over by Vedanta Resources, a company listed on the London Stock Exchange. The government company has been closely associated with the Indian Aluminium Industry, in a pivotal role. Mr. Rajesh Kumar is the current CEO & Whole Time Director of the company.

Aluminium–lithium alloys are a set of alloys of aluminium and lithium, often also including copper and zirconium. Since lithium is the least dense elemental metal, these alloys are significantly less dense than aluminium. Commercial Al–Li alloys contain up to 2.45% lithium by mass.

6061 aluminium alloy is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminium for general-purpose use.

In the automotive industry, alloy wheels are wheels that are made from an alloy of aluminium or magnesium. Alloys are mixtures of a metal and other elements. They generally provide greater strength over pure metals, which are usually much softer and more ductile. Alloys of aluminium or magnesium are typically lighter for the same strength, provide better heat conduction, and often produce improved cosmetic appearance over steel wheels. Although steel, the most common material used in wheel production, is an alloy of iron and carbon, the term "alloy wheel" is usually reserved for wheels made from nonferrous alloys.

The Hiduminium alloys or R.R. alloys are a series of high-strength, high-temperature aluminium alloys, developed for aircraft use by Rolls-Royce ("RR") before World War II. They were manufactured and later developed by High Duty Alloys Ltd. The name Hi-Du-Minium is derived from that of High Duty Aluminium Alloys.

AlSiC, pronounced "alsick", is a metal matrix composite consisting of aluminium matrix with silicon carbide particles. It has high thermal conductivity, and its thermal expansion can be adjusted to match other materials, e.g. silicon and gallium arsenide chips and various ceramics. It is chiefly used in microelectronics as substrate for power semiconductor devices and high density multi-chip modules, where it aids with removal of waste heat.

Sustained load cracking, or SLC, is a metallurgical phenomenon that occasionally develops in pressure vessels and structural components under stress for sustained periods of time.

2219 aluminium alloy is an alloy in the wrought aluminium-copper family. It can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys have high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys. To compensate for the lower corrosion resistance, 2219 aluminium can be clad in a commercially pure alloy such as 1050 or painted. This alloy is commonly formed by both extrusion and forging, but is not used in casting.

5754 aluminium–magnesium alloy is an alloy in the wrought aluminium -magnesium family. It is closely related to the alloys 5154 and 5454. Of the three 5x54 alloys, 5754 is the least alloyed, but only by a small amount. It is used in similar applications. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility.

6082 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family. It is one of the more popular alloys in its series, although it is not strongly featured in ASTM standards. It is typically formed by extrusion, cold and hot stamping, and rolling, but as a wrought alloy it is not used in casting. It can also be forged and clad, but that is not common practice with this alloy. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility.