Related Research Articles

Monel is a group of alloys of nickel and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper.

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool. While the tool is traversed along the joint line, it mechanically intermixes the two pieces of metal, and forges the hot and softened metal by the mechanical pressure, which is applied by the tool, much like joining clay, or dough. It is primarily used on wrought or extruded aluminium and particularly for structures which need very high weld strength. FSW is capable of joining aluminium alloys, copper alloys, titanium alloys, mild steel, stainless steel and magnesium alloys. More recently, it was successfully used in welding of polymers. In addition, joining of dissimilar metals, such as aluminium to magnesium alloys, has been recently achieved by FSW. Application of FSW can be found in modern shipbuilding, trains, and aerospace applications.

Aluminum building wiring is a type of electrical wiring for residential construction or houses that uses aluminum electrical conductors. Aluminum provides a better conductivity-to-weight ratio than copper, and therefore is also used for wiring power grids, including overhead power transmission lines and local power distribution lines, as well as for power wiring of some airplanes. Utility companies have used aluminum wire for electrical transmission in power grids since around the late 1800s to the early 1900s. It has cost and weight advantages over copper wires. Aluminum in power transmission and distribution applications is still the preferred wire material today.

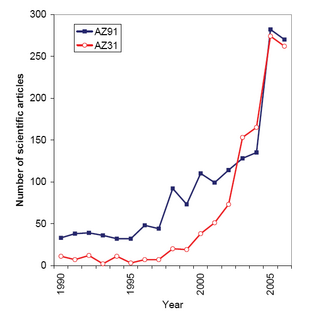

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Aluminium–lithium alloys are a set of alloys of aluminium and lithium, often also including copper and zirconium. Since lithium is the least dense elemental metal, these alloys are significantly less dense than aluminium. Commercial Al–Li alloys contain up to 2.45% lithium by mass.

6061 aluminium alloy is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminium for general-purpose use.

7075 aluminium alloy (AA7075) is an aluminium alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the alloys from the 2000 series. It is one of the most commonly used aluminium alloys for highly stressed structural applications and has been extensively used in aircraft structural parts.

AA 6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. The standard controlling its composition is maintained by The Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminium alloy HE9.

Alclad is a corrosion-resistant aluminium sheet formed from high-purity aluminium surface layers metallurgically bonded to high-strength aluminium alloy core material. It has a melting point of about 500 °C (932 °F). Alclad is a trademark of Alcoa but the term is also used generically.

The skin of an aircraft is the outer surface which covers much of its wings and fuselage. The most commonly used materials are aluminum and aluminium alloys with other metals, including zinc, magnesium and copper.

Carlton Forge Works is an aerospace manufacturing company that produces seamless rolled rings. Carlton was found in 1929 and was privately held. According to Manta and Business Week, the company has about 250-300 employees. The company was previously owned by Allan Carlton.

Friction stir processing (FSP) is a method of changing the properties of a metal through intense, localized plastic deformation. This deformation is produced by forcibly inserting a non-consumable tool into the workpiece, and revolving the tool in a stirring motion as it is pushed laterally through the workpiece. The precursor of this technique, friction stir welding, is used to join multiple pieces of metal without creating the heat affected zone typical of fusion welding.

2219 aluminium alloy is an alloy in the wrought aluminium-copper family. It can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys have high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys. To compensate for the lower corrosion resistance, 2219 aluminium can be clad in a commercially pure alloy such as 1050 or painted. This alloy is commonly formed by both extrusion and forging, but is not used in casting.

5456 aluminium–magnesium alloy is an alloy in the wrought aluminium-magnesium family. While it is closely related to 5356 aluminium alloy, it is used in structural applications, like most other aluminium-magnesium alloys, and not as filler for welding. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. It is susceptible to exfoliation corrosion when held at temperatures above 65 °C (150 °F) for extended periods of time.

Aluminium 7050 alloy is a heat treatable alloy. It has high toughness, high strength. It has high stress corrosion cracking resistance. It has electric conductivity of value having 40 percent of copper. 7050 aluminium is known as a commercial aerospace alloy.

Aluminium 7150 alloy is a heat treatable wrought alloy. It is used in the aerospace industry for manufacturing aircraft components. Heat treatment can improve its anti-corrosion properties with a low corresponding decrease in strength.

7178 aluminum alloy is wrought alloy. It has high zinc content. After annealing, aluminum alloy 7178 has high machinability. Resistance welding can be used.

7475 aluminum alloy (Adirium) is a wrought alloy with high zinc weight percentage. It also contains magnesium, silicon and chromium.

Aluminium–copper alloys (AlCu) are aluminium alloys that consist largely of aluminium (Al) and traces of copper (Cu) as the main alloying elements. Important grades also contain additives of magnesium, iron, nickel and silicon, often manganese is also included to increase strength. The main area of application is aircraft construction. The alloys have medium to high strength and can be age hardened. They are both wrought alloy. Also available as cast alloy. Their susceptibility to corrosion and their poor weldability are disadvantageous.

References

- 1 2 3 "7049 aluminum alloy". 31 August 2012. Archived from the original on 2020-09-20.

- ↑ "Aluminum 7049 properties".

- 1 2 "Alumum alloy 7049". Archived from the original on 2016-09-03.

- ↑ "7049 aluminum alloy". Archived from the original on 2019-08-31.

- 1 2 3 "Alloy 7049 applications" (PDF). Archived (PDF) from the original on 2019-02-15.