Related Research Articles

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength.

Duralumin is a trade name for one of the earliest types of age-hardenable aluminium alloys. The term is a combination of Dürener and aluminium. Its use as a trade name is obsolete. Today the term mainly refers to aluminium-copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 and 2024 alloys used in airframe fabrication.

The term semi-monocoque or semimonocoque refers to a stressed shell structure that is similar to a true monocoque, but which derives at least some of its strength from conventional reinforcement. Semi-monocoque construction is used for, among other things, aircraft fuselages, car bodies and motorcycle frames.

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness. They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

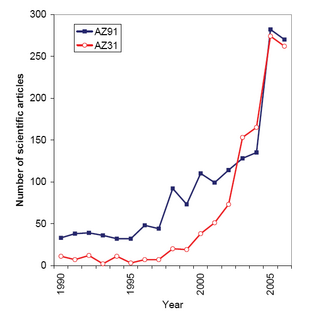

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties.

An aluminium alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Aluminium–lithium alloys are a set of alloys of aluminium and lithium, often also including copper and zirconium. Since lithium is the least dense elemental metal, these alloys are significantly less dense than aluminium. Commercial Al–Li alloys contain up to 2.45% lithium by mass.

6061 is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminium for general-purpose use.

7075 aluminium alloy (AA7075) is an aluminium alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the alloys from the 2000 series. It is one of the most commonly used aluminium alloys for highly stressed structural applications and has been extensively used in aircraft structural parts.

2024 aluminium alloy is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. In older systems of terminology, 2XXX series alloys were known as duralumin, and this alloy was named 24ST.

Alclad is a corrosion-resistant aluminium sheet formed from high-purity aluminium surface layers metallurgically bonded to high-strength aluminium alloy core material. It has a melting point of about 500 °C (932 °F). Alclad is a trademark of Alcoa but the term is also used generically.

The Hiduminium alloys or R.R. alloys are a series of high-strength, high-temperature aluminium alloys, developed for aircraft use by Rolls-Royce ("RR") before World War II. They were manufactured and later developed by High Duty Alloys Ltd. The name Hi-Du-Minium is derived from that of High Duty Aluminium Alloys.

AA 2519 is an aluminium alloy principally containing copper (5.3–6.4%) as an alloying element. It also contains 0.25% silicon, 0.30% iron, 0.10–0.50% manganese, 0.05–0.40% magnesium, 0.10% zinc, 0.02–0.10% titanium, 0.05–0.15% vanadium, 0.10–0.25% zirconium, 0.40% silicon-iron compounds, and up to 0.15% trace elements. The density of 2519 aluminium is 2820 kg/m3. It was first registered in 1985, in the United States.

2014 aluminium alloy (aluminum) is an aluminium-based alloy often used in the aerospace industry.

7079 aluminium alloy is a high strength, heat treatable wrought aluminium alloy used in the aircraft industry. Age-hardening heat treatment enhances the characteristics of AL 7079, eliminating variations in characteristics seen in Aluminium 7075.

7068 aluminium alloy is one of the strongest commercially available aluminium alloys, with a tensile strength comparable to that of some steels. This material, also known as an aircraft alloy, is heat treatable.

Aluminium 7050 alloy is a heat treatable alloy. It has high toughness, high strength. It has high stress corrosion cracking resistance. It has electric conductivity of value having 40 percent of copper. 7050 aluminium is known as a commercial aerospace alloy.

6013 aluminium alloy consist of magnesium, silicon, copper, manganese, iron, zinc, chromium, and titanium as minor alloying elements.

2017 Aluminium alloy has copper, iron, magnesium, manganese and silicon as main alloying elements.

References

- 1 2 3 4 5 "2090 Aluminium alloy properties". 6 May 2013.

- ↑ "2090 Aluminium alloy properties". Archived from the original on 2021-01-22.