Related Research Articles

Aluminium–silicon alloys or Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system, i.e., Aluminium-silicon alloys (AlSi) that consist predominantly of aluminum - with silicon as the quantitatively most important alloying element. Pure AlSi alloys cannot be hardened, the commonly used alloys AlSiCu and AlSiMg can be hardened. The hardening mechanism corresponds to that of AlCu and AlMgSi. The rarely used wrought alloys in the 4000 series and the predominantly used cast alloys are standardized in the 40000 series. AlSi alloys are by far the most important of all aluminum cast materials. They are suitable for all casting processes and have excellent casting properties. Important areas of application are in car parts, including engine blocks and pistons. In addition, their use as a functional material for high-energy heat storage in electric vehicles is currently being focused on.

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas. A filler metal is normally used, though some welds, known as autogenous welds, or fusion welds do not require it. When helium is used, this is known as heliarc welding. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma. TIG welding is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys. The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds. However, TIG welding is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques. A related process, plasma arc welding, uses a slightly different welding torch to create a more focused welding arc and as a result is often automated.

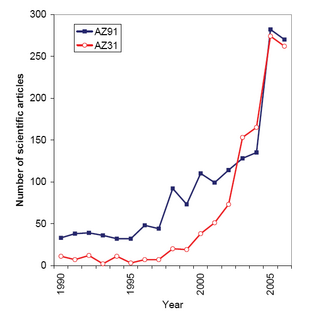

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Magnalium is an aluminium alloy with 5% magnesium and 95% aluminum.

An aluminium alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

6061 is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminium for general-purpose use.

5086 is an aluminium–magnesium alloy, primarily alloyed with magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material.

AA 6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. The standard controlling its composition is maintained by The Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminium alloy HE9.

In the automotive industry, alloy wheels are wheels that are made from an alloy of aluminium or magnesium. Alloys are mixtures of a metal and other elements. They generally provide greater strength over pure metals, which are usually much softer and more ductile. Alloys of aluminium or magnesium are typically lighter for the same strength, provide better heat conduction, and often produce improved cosmetic appearance over steel wheels. Although steel, the most common material used in wheel production, is an alloy of iron and carbon, the term "alloy wheel" is usually reserved for wheels made from nonferrous alloys.

5083 aluminium alloy is an aluminium–magnesium alloy with magnesium and traces of manganese and chromium. It is highly resistant to attack by seawater and industrial chemicals.

The skin of an aircraft is the outer surface which covers much of its wings and fuselage. The most commonly used materials are aluminum and aluminium alloys with other metals, including zinc, magnesium and copper.

AA 2519 is an aluminium alloy principally containing copper (5.3–6.4%) as an alloying element. It also contains 0.25% silicon, 0.30% iron, 0.10–0.50% manganese, 0.05–0.40% magnesium, 0.10% zinc, 0.02–0.10% titanium, 0.05–0.15% vanadium, 0.10–0.25% zirconium, 0.40% silicon-iron compounds, and up to 0.15% trace elements. The density of 2519 aluminium is 2820 kg/m3. It was first registered in 1985, in the United States.

AA 2319 is an aluminium alloy principally containing copper (5.8–6.8%) as an alloying element. It also contains ≤0.20% silicon, ≤0.30% iron, 0.20–0.40% manganese, ≤0.02% magnesium, ≤0.10% zinc, 0.10–0.20% titanium, 0.05–0.15% vanadium, 0.10–0.25% zirconium, ≤0.0003% beryllium and up to 0.15% trace elements. The density of 2319 aluminium is 2840 kg/m3. This alloy was first registered in 1958, in the United States.

2014 aluminium alloy (aluminum) is an aluminium-based alloy often used in the aerospace industry.

5154 aluminium alloy is an alloy in the wrought aluminium-magnesium family. As an aluminium-magnesium alloy, it combines moderate-to-high strength with excellent weldability. 5154 aluminium is commonly used in welded structures such as pressure vessels and ships. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. It is generally not clad.

5454 aluminium–magnesium alloy is an alloy in the wrought aluminium-magnesium family. It is closely related to 5154 aluminium alloy. As an aluminium-magnesium alloy, it combines moderate-to-high strength with excellent weldability. Like 5154, 5454 aluminium is commonly used in welded structures such as pressure vessels and ships. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. It is generally not clad.

5456 aluminium–magnesium alloy is an alloy in the wrought aluminium-magnesium family. While it is closely related to 5356 aluminium alloy, it is used in structural applications, like most other aluminium-magnesium alloys, and not as filler for welding. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. It is susceptible to exfoliation corrosion when held at temperatures above 65 °C (150 °F) for extended periods of time.

6060 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family. It is much more closely related to the alloy 6063 than to 6061. The main difference between 6060 and 6063 is that 6063 has a slightly higher magnesium content. It can be formed by extrusion, forging or rolling, but as a wrought alloy it is not used in casting. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility.

6082 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family. It is one of the more popular alloys in its series, although it is not strongly featured in ASTM standards. It is typically formed by extrusion and rolling, but as a wrought alloy it is not used in casting. It can also be forged and clad, but that is not common practice with this alloy. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility.

4043 aluminium alloy is a wrought aluminium alloy with good corrosion resistance typically used as filler material for welding of aluminium parts. It contains high amounts of silicon and trace amounts of other metals. It is grey in appearance and is sold as either welding wire or welding rod for TIG/MIG processes.

References

- ↑ O'Brien, Robert L. (ed.), Jefferson's Welding Encyclopedia, American Welding Society, 1997, p. 28

- ↑ Aluminum Workshop: The best filler wire for welding 6061-T6 aluminum. Retrieved on 2014-12-04.