Lace is a delicate fabric made of yarn or thread in an open weblike pattern, made by machine or by hand. Generally, lace is split into two main categories, needlelace and bobbin lace, although there are other types of lace, such as knitted or crocheted lace. Other laces such as these are considered as a category of their specific craft. Knitted lace, therefore, is an example of knitting. This article considers both needle lace and bobbin lace.

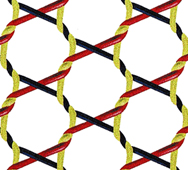

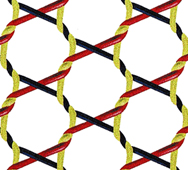

Bobbin lace is a lace textile made by braiding and twisting lengths of thread, which are wound on bobbins to manage them. As the work progresses, the weaving is held in place with pins set in a lace pillow, the placement of the pins usually determined by a pattern or pricking pinned on the pillow.

A bobbin or spool is a spindle or cylinder, with or without flanges, on which yarn, thread, wire, tape or film is wound. Bobbins are typically found in industrial textile machinery, as well as in sewing machines, fishing reels, tape measures, film rolls, cassette tapes, within electronic and electrical equipment, and for various other applications.

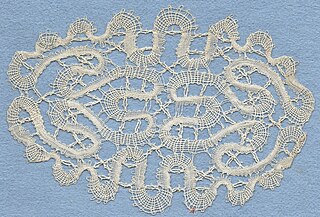

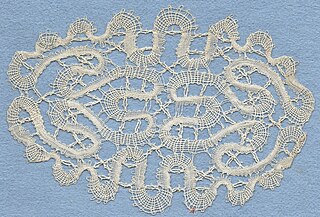

Guipure lace is a type of bobbin lace. It connects the motifs with bars or plaits rather than net or mesh.

Punto a groppo is type of lace made without bobbins (weights). It originated in Italy, possibly Milan, in the 16th century and usually incorporated geometric patterns. It is the precursor to bobbin lace. Remaining samples of this lace are rare.

Bobbinet tulle or genuine tulle is a specific type of tulle which has been made in the United Kingdom since the invention of the bobbinet machine. John Heathcoat coined the term "bobbin net", or bobbinet as it is spelled today, to distinguish this machine-made tulle from the handmade "pillow lace", produced using a lace pillow to create bobbin lace. Machines based on his original designs are still in operation today producing fabrics in Perry Street, Chard, Somerset, UK.

Bucks point is a bobbin lace from the South East of England. "Bucks" is short for Buckinghamshire, which was the main centre of production. The lace was also made in the nearby counties of Bedfordshire and Northamptonshire. Bucks point is very similar to the French Lille lace, and thus is often called English Lille. It is also similar to Mechlin lace and Chantilly lace.

Torchon lace is a bobbin lace that was made all over Europe. It is continuous, with the pattern made at the same time as the ground. Typical basic stitches include whole stitch, half stitch, and twists, and common motifs include spiders and fans. Torchon lace was notable historically for being coarse and strong, as well as consisting of simple geometric patterns and straight lines. It did not use representational designs, for the most part.

Mundillo is a craft of handmade bobbin lace that is cultivated and honored on the island of Puerto Rico and Panama.

Metal lace describes a type of lace made from metal or metallic threads, such as gold, silver, or copper. The designs can be worked on a textile ground, or the lace can completely be made from metallic threads. It is mainly used as an embellishment for military uniforms, fashionable, ceremonial and theatrical dress, and ecclesiastical textiles.

Lace machines took over the commercial manufacture of lace during the nineteenth century.

The Barmen lace machine makes perfect copies of torchon lace and the simpler hand-made bobbin lace. Its bobbins imitate the movements of the bobbins of the hand-made lace maker.

Cluny lace is a bobbin lace style, worked as a continuous piece. It is a heavy plaited lace of geometric design, often with radiating thin, pointed wheatears. It is a guipure style of lace.

Genoese lace is bobbin lace from Genoa. It is a guipure style of lace.

Part lace or sectional lace is a way of making bobbin lace. It characterises various styles, such as Honiton lace or Brussels lace.

Bobbin tape lace is bobbin lace where the design is formed of one or more tapes curved so they make an attractive pattern. The tapes are made at the same time as the rest of the lace, and are joined to each other, or themselves, using a crochet hook.

Russian lace is a bobbin tape lace. The tape is made with bobbins at the same time as the rest of the lace, curving back on itself, and joined using a crochet hook. It was made in Russia, but similar laces made elsewhere are also called Russian lace.

Mesh grounded lace is a continuous bobbin lace also known as straight lace. Continuous bobbin lace is made in one piece on a lace pillow. The threads of the ground enter motifs, then leave to join the ground again further down the process, all made in one go. This is different from part lace, where the motifs are created separately, then joined together afterwards.

The Pusher machine was a lace making machine, based on the bobbinet, that was invented in 1812 Samuel Clark and James Mart.

Ipswich lace is a historical fashion accessory, the only known American hand-made bobbin lace to be commercially produced. Centered in the coastal town of Ipswich, Massachusetts north of Boston, a community of lacemaking arose in the 18th century. Puritan settlers to the area likely made and wore lace as early as 1634, because Sumptuary laws from the early colonial records indicate this activity. In fact, the earliest known record of the act of lacemaking in the region comes from a court case in 1654 associated with the home of Governor John Endicott. An indentured servant in the household accused the governor's son Zerubbabel with assault, which occurred while she was working at her lace cushion. Earliest known records of the commercial production indicate that lace produced by local women was used to barter for goods in the 1760s, as denoted by ledger account books belonging to local merchants. These laces were sold in the region from Boston to Maine.