Crochet is a process of creating textiles by using a crochet hook to interlock loops of yarn, thread, or strands of other materials. The name is derived from the French term crochet, which means 'hook'. Hooks can be made from different materials, sizes, and types. The key difference between crochet and knitting, beyond the implements used for their production, is that each stitch in crochet is completed before you begin the next one, while knitting keeps many stitches open at a time. Some variant forms of crochet, such as Tunisian crochet and Broomstick lace, do keep multiple crochet stitches open at a time.

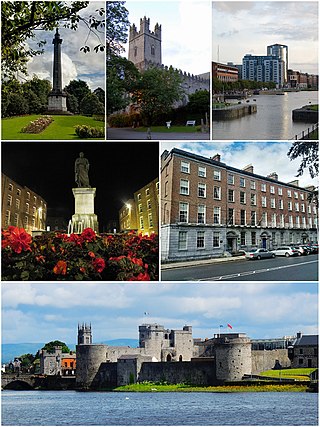

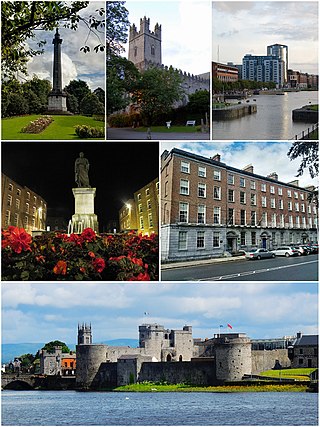

Limerick is a city in western Ireland, in County Limerick. It is in the province of Munster and is in the Mid-West which comprises part of the Southern Region. With a population of 102,287 at the 2022 census, Limerick is the third-most populous urban area in Ireland, and the fourth-most populous city on the island of Ireland. It was founded by Scandinavian settlers in 812, during the Viking Age.

Lace is a delicate fabric made of yarn or thread in an open weblike pattern, made by machine or by hand. Generally, lace is split into two main categories, needlelace and bobbin lace, although there are other types of lace, such as knitted or crocheted lace. Other laces such as these are considered as a category of their specific craft. Knitted lace, therefore, is an example of knitting. This article considers both needle lace and bobbin lace.

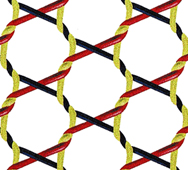

Bobbin lace is a lace textile made by braiding and twisting lengths of thread, which are wound on bobbins to manage them. As the work progresses, the weaving is held in place with pins set in a lace pillow, the placement of the pins usually determined by a pattern or pricking pinned on the pillow.

Needle lace is a type of lace created using a needle and thread to create hundreds of small stitches to form the lace itself.

John Heathcoat was an English inventor from Duffield, Derbyshire. During his apprenticeship he made an improvement to the warp-loom, so as to produce mitts of a lace-like appearance. He set up his own business in Nottingham but was forced to move away to Hathern in Leicestershire, and after this new factory was attacked by former Luddites in 1816 he moved the business to Tiverton in Devon where it became most successful and established the Tiverton lace-making industry.

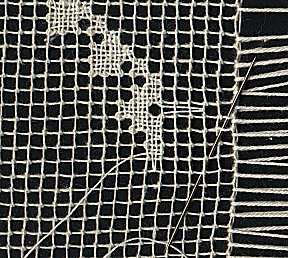

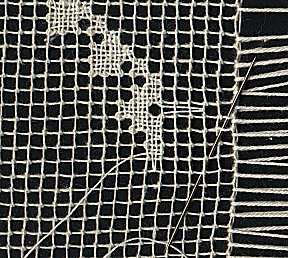

Filet lace is the general word used for all the different techniques of embroidery on knotted net. It is a hand made needlework created by weaving or embroidery using a long blunt needle and a thread on a ground of knotted net lace or filet work made of square or diagonal meshes of the same sizes or of different sizes. Lacis uses the same technique but is made on a ground of leno or small canvas, and the style known as Buratto is similarly on woven and not knotted foundations.

Tønder lace is a point-ground type of handmade bobbin lace identified with the Tønder region of Denmark since about 1850, although lace of many types has been made there since as early as 1650. The term is also used more broadly, to refer to any bobbin lace made in Denmark.

Alençon lace or point d'Alençon is a needle lace that originated in Alençon, France. It is sometimes called the "Queen of lace." Lace making began in Alençon during the 16th century and the local industry was rapidly expanded during the reign of Louis XIV by Jean-Baptiste Colbert, who established a Royal Workshop in the town to produce lace in the Venetian style in 1665. The purpose of establishing this workshop was to reduce the French court's dependence on expensive foreign imports. Marthe La Perrière had modified the Venetian technique and Alençon emerged as a unique style around 1675 after Colbert's monopoly ended. The lace employs a mesh ground and incorporates pattern motifs with a raised outline of closely packed buttonhole stitches, an outer edge decorated with picots, and open areas with decorative fillings.

Youghal lace is a needle lace inspired by Italian needle lace and developed in Youghal, County Cork, Ireland.

Tambour lace refers to a family of lace made by stretching a fine net over a frame and creating a chain stitch, known as tambour, using a fine, pointed hook to reach through the net and draw the working thread through.

Needlerun net is a family of laces created by using a needle to embroider on a net ground.

Carrickmacross lace is a form of lace that may be described as decorated net. A three-layer 'sandwich' is made consisting of the pattern, covered with, first, machine-made net and then fine muslin, through which the pattern can be seen. A thick outlining thread is stitched down along the lines of the pattern, sewing net and fabric together. Loops of thread known as 'twirls' are also couched along the outer edge. The excess fabric is then cut away. Some of the net is then usually decorated further with needle-run stitches or small button-holed rings known as 'pops'. Occasionally bars of buttonhole stitches are worked over fabric and net before both are cut away.

A stocking frame was a mechanical knitting machine used in the textiles industry. It was invented by William Lee of Calverton near Nottingham in 1589. Its use, known traditionally as framework knitting, was the first major stage in the mechanisation of the textile industry, and played an important part in the early history of the Industrial Revolution. It was adapted to knit cotton and to do ribbing, and by 1800 had been adapted as a lace making machine.

Bobbinet tulle or genuine tulle is a specific type of tulle which has been made in the United Kingdom since the invention of the bobbinet machine. John Heathcoat coined the term "bobbin net", or bobbinet as it is spelled today, to distinguish this machine-made tulle from the handmade "pillow lace", produced using a lace pillow to create bobbin lace. Machines based on his original designs are still in operation today producing fabrics in Perry Street, Chard, Somerset, UK.

Brussels lace is a type of pillow lace that originated in and around Brussels. The term "Brussels lace" has been broadly used for any lace from Brussels; however, strictly interpreted, the term refers to bobbin lace, in which the pattern is made first, and the ground, or réseau added, also using bobbin lace. Brussels lace is not to be confused with Brussels point, which is a type of needle lace, though sometimes also called "Brussels lace".

Irish lace has always been an important part of the Irish needlework tradition. Both needlepoint and bobbin laces were made in Ireland before the middle of the eighteenth century, but never, apparently, on a commercial scale. It was promoted by Irish aristocrats such as Lady Arabella Denny, the famous philanthropist, who used social and political connections to support the new industry and promote the sale of Irish lace abroad. Lady Denny, working in connection with the Dublin Society, introduced lace-making into the Dublin workhouses, especially among the children there. It is thought that it was an early form of Crochet, imitating the appearance of Venetian Gros Point lace.

The Nottingham Industrial Museum is a volunteer-run museum situated in part of the 17th-century stables block of Wollaton Hall, located in a suburb of the city of Nottingham. The museum won the Nottinghamshire Heritage Site of the Year Award 2012, a local accolade issued by Experience Nottinghamshire. The Museum collection closed in 2009 after Nottingham City Council withdrew funding, but has since reopened at weekends and bank holidays, helped by a £91,000 government grant, and run by volunteers. The museum contains a display of local textiles machinery, transport, telecommunications, mining and engineering technology. There is a display of cycles, motorcycles, and motor cars. There are examples of significant lace-making machinery. It also houses an operational beam engine, from the Basford, Nottingham pumping station.

Lace machines took over the commercial manufacture of lace during the nineteenth century.

Embroidered lace is embroidered on a base using a needle. The base varies according to the type.