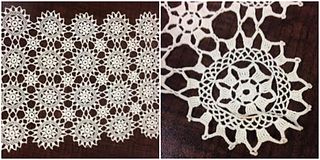

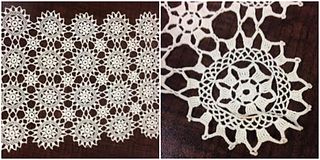

Lace is a delicate fabric made of yarn or thread in an open weblike pattern, made by machine or by hand. Generally, lace is split into two main categories, needlelace and bobbin lace, although there are other types of lace, such as knitted or crocheted lace. Other laces such as these are considered as a category of their specific craft. Knitted lace, therefore, is an example of knitting. This article considers both needle lace and bobbin lace.

Bobbin lace is a lace textile made by braiding and twisting lengths of thread, which are wound on bobbins to manage them. As the work progresses, the weaving is held in place with pins set in a lace pillow, the placement of the pins usually determined by a pattern or pricking pinned on the pillow.

An overlock is a kind of stitch that sews over the edge of one or two pieces of cloth for edging, hemming, or seaming. Usually an overlock sewing machine will cut the edges of the cloth as they are fed through, though some are made without cutters. The inclusion of automated cutters allows overlock machines to create finished seams easily and quickly. An overlock sewing machine differs from a lockstitch sewing machine in that it uses loopers fed by multiple thread cones rather than a bobbin. Loopers serve to create thread loops that pass from the needle thread to the edges of the fabric so that the edges of the fabric are contained within the seam.

Chantilly lace is a handmade bobbin lace named after the city of Chantilly, France, in a tradition dating from the 17th century. The famous silk laces were introduced in the 18th century. Chantilly lace, was also produced in the 19th century but this one was actually made not in Chantilly area but in the French Norman town Bayeux and in Geraardsbergen, now in Belgium.

Tønder lace is a point-ground type of handmade bobbin lace identified with the Tønder region of Denmark since about 1850, although lace of many types has been made there since as early as 1650. The term is also used more broadly, to refer to any bobbin lace made in Denmark.

Tenerife lace or "roseta canaria" is a needle lace from Canary Islands. The first name comes from the fact that the lace made on the islands was exported from that island. The origin of this lace is uncertain and it is not known on which island the technique was born. In Tenerife this style may be referred to as"Brazilian" lace.

Chenille is a type of yarn, or the fabric made from it. Chenille is the French word for caterpillar, whose fur the yarn is supposed to resemble.

A knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion. There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles, push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers.

Warp knitting is defined as a loop-forming process in which the yarn is fed into the knitting zone, parallel to the fabric selvage. It forms vertical loops in one course and then moves diagonally to knit the next course. Thus the yarns zigzag from side to side along the length of the fabric. Each stitch in a course is made by many different yarns. Each stitch in one wale is made by several different yarns.

Bobbinet tulle or genuine tulle is a specific type of tulle which has been made in the United Kingdom since the invention of the bobbinet machine. John Heathcoat coined the term "bobbin net", or bobbinet as it is spelled today, to distinguish this machine-made tulle from the handmade "pillow lace", produced using a lace pillow to create bobbin lace. Machines based on his original designs are still in operation today producing fabrics in Perry Street, Chard, Somerset, UK.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, with color and patterns, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of coloring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Torchon lace is a bobbin lace that was made all over Europe. It is continuous, with the pattern made at the same time as the ground. Typical basic stitches include whole stitch, half stitch, and twists, and common motifs include spiders and fans. Torchon lace was notable historically for being coarse and strong, as well as consisting of simple geometric patterns and straight lines. It did not use representational designs, for the most part.

Lace machines took over the commercial manufacture of lace during the nineteenth century.

Greek lace is considered one of the earliest forms of all lace. Some types of Greek lace include reticella, Roman lace, cutwork, Venetian guipure, and Greek point lace

Maltese lace is a style of bobbin lace made in Malta. It is a guipure style of lace. It is worked as a continuous width on a tall, thin, upright lace pillow. Bigger pieces are made of two or more parts sewn together.

Mesh grounded lace is a continuous bobbin lace also known as straight lace. Continuous bobbin lace is made in one piece on a lace pillow. The threads of the ground enter motifs, then leave to join the ground again further down the process, all made in one go. This is different from part lace, where the motifs are created separately, then joined together afterwards.

The term Hedebo embroidery covers several forms of white embroidery which originated in the Hedebo (heathland) region of Zealand, Denmark, in the 1760s. The varied techniques which evolved over the next hundred years in the farming community were subsequently developed by the middle classes until around 1820. They were applied to articles of clothing such as collars and cuffs but were also used to decorate bed linen.

The schiffli embroidery machine is a multi-needle, industrial embroidery machine. It was invented by Isaak Gröbli in 1863. It was used to create various types of machine embroidery and certain types of lace. It was especially used in the textile industry of eastern Switzerland and Saxony Germany, but also in the United Kingdom and the United States. Schiffli machines evolved from, and eventually replaced manually operated "hand embroidery" machines. The hand embroidery machine used double ended needles and passed the needles completely through the fabric. Each needle had a single, continuous thread. Whereas the schiffli machine used a lock stitch, the same technique used by the sewing machine. By the early twentieth century schiffli machines had standardized to ten and fifteen meters in width and used more than 600 needles.

Ipswich lace is a historical fashion accessory, the only known American hand-made bobbin lace to be commercially produced. Centered in the coastal town of Ipswich, Massachusetts north of Boston, a community of lacemaking arose in the 18th century. Puritan settlers to the area likely made and wore lace as early as 1634, because Sumptuary laws from the early colonial records indicate this activity. In fact, the earliest known record of the act of lacemaking in the region comes from a court case in 1654 associated with the home of Governor John Endicott. An indentured servant in the household accused the governor's son Zerubbabel with assault, which occurred while she was working at her lace cushion. Earliest known records of the commercial production indicate that lace produced by local women was used to barter for goods in the 1760s, as denoted by ledger account books belonging to local merchants. These laces were sold in the region from Boston to Maine.

Cogne lace is a handmade bobbin lace that is made in Cogne, in the Aosta Valley in Italy. It takes the form of strips of lace, due to the manner in which it is made on a drum.