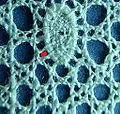

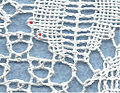

Mesh grounded lace is a continuous bobbin lace also known as straight lace. Continuous bobbin lace is made in one piece on a lace pillow. The threads of the ground enter motifs, then leave to join the ground again further down the process, all made in one go. This is different from part lace, where the motifs are created separately, then joined together afterwards.

Contents

- Classification: Context and sub types of mesh laces

- Worker pair versus two pair per pin

- Ring pair

- Belgian color code

- Corners and joining

- References

Mesh grounded lace is a group of lace types that may look very different but share several common properties.