In commerce, supply-chain management (SCM), the management of the flow of goods and services, involves the movement and storage of raw materials, of work-in-process inventory, and of finished goods from point of origin to point of consumption. Interconnected or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain. Supply-chain management has been defined as the "design, planning, execution, control, and monitoring of supply-chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand and measuring performance globally."

SCM practice draws heavily from the areas of industrial engineering, systems engineering, operations management, logistics, procurement, information technology, and marketing and strives for an integrated approach. Marketing channels play an important role in supply-chain management. Current research in supply-chain management is concerned with topics related to sustainability and risk management, among others. Some suggest that the “people dimension” of SCM, ethical issues, internal integration, transparency/visibility, and human capital/talent management are topics that have, so far, been underrepresented on the research agenda.

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics is the management of the flow of things between the point of origin and the point of consumption in order to meet requirements of customers or corporations. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items. The logistics of physical items usually involves the integration of information flow, materials handling, production, packaging, inventory, transportation, warehousing, and often security.

Materiel, refers to supplies, equipment, and weapons in military supply chain management, and typically supplies and equipment only in a commercial supply chain context.

Air Force Materiel Command (AFMC) is a major command (MAJCOM) of the United States Air Force (USAF). AFMC was created on July 1, 1992, through the amalgamation of the former Air Force Logistics Command (AFLC) and the former Air Force Systems Command (AFSC).

Purchasing refers to a business or organization attempting to acquire goods or services to accomplish its goals. Although there are several organizations that attempt to set standards in the purchasing process, processes can vary greatly between organizations. Typically the word “purchasing” is not used interchangeably with the word “procurement”, since procurement typically includes expediting, supplier quality, and transportation and logistics (T&L) in addition to purchasing.

The Defense Logistics Agency (DLA) is a combat support agency in the United States Department of Defense, with more than 26,000 civilian and military personnel throughout the world. Located in 48 states and 28 countries, DLA provides supplies to the military services and supports their acquisition of weapons, fuel, repair parts, and other materials. The agency also disposes of excess or unusable equipment through various programs.

Air Materiel Command (AMC) was a United States Army Air Forces and United States Air Force command. Its headquarters was located at Wright-Patterson Air Force Base, Ohio. In 1961, the command was redesignated the Air Force Logistics Command with some of its functions transferred to the new Air Force Systems Command.

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the U.S. Department of Defense.

Integrated logistic support (ILS) is an integrated and iterative process for developing materiel and a support strategy that optimizes functional support, leverages existing resources, and guides the system engineering process to quantify and lower life cycle cost and decrease the logistics footprint, making the system easier to support. Although originally developed for military purposes, it is also widely used in commercial product support or customer service organisations.

The term supply management, also called procurement, describes the methods and processes of modern corporate or institutional buying. This may be for the purchasing of supplies for internal use referred to as indirect goods and services, purchasing raw materials for the consumption during the manufacturing process, or for the purchasing of goods for inventory to be resold as products in the distribution and retail process.

Marine Corps Systems Command (MCSC) is the acquisition command of the United States Marine Corps, made up of Marines, sailors, civilians and contractors. As the only systems command in the Marine Corps, MCSC serves as Head of Contracting Authority and exercises technical authority for all marine Corps ground weapon and information technology programs. MCSC is headquartered at Marine Corps Base Quantico.

Logistics Support Analysis (LSA) is a structured approach to increase efficiency of maintenance and reduces the cost of providing support by preplanning all aspects of Integrated Logistics Support. A successful LSA will define those support requirements that are ideal for the system design.

Medical materiel are medical supply technicians employed by hospitals, clinics, and the military; these professionals are responsible for managing and requisitioning, receiving, storing, issuing, safeguarding and accounting for supplies and medical equipment used in healthcare. In addition, medical supply technicians are responsible for maintaining requirements and records on storage/war reserve materiel; establishing stock control levels and inventory control; controlled medical items ; and delivering supplies and equipment to the customers. Medical logistics is often confused with and falls over the professional group in the hospital, the medical materiel/medical supply technicians.

Daher, or DAHER, is a French industrial conglomerate. Daher works in the aerospace, defence, nuclear, and automotive industrial sectors in the fields of manufacturing, services and transport.

In military contexts, a train is the logistical transport elements accompanying a military force. Often called a supply train or baggage train, it has the job of providing materiel for their associated combat forces when in the field. When focused on provision of artillery and ammunition it may be termed an artillery train; for sieges, requiring siege engines in addition, the required transport was called a siege train. These military terms predate, and do not imply a railway train, though railways are often employed for modern logistics, and can include armoured trains.

Sierra Army Depot (SIAD) is a United States Army post and military equipment storage facility located near the unincorporated community of Herlong, California. It was built in 1942 as one of several ammunition storage facilities located far enough inland to be safe from Japanese attack. The site also met the requirement that the depot be in a dry and isolated area.

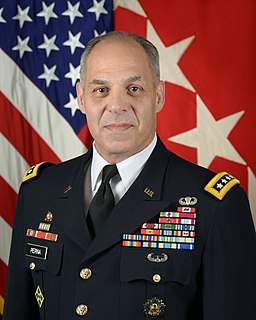

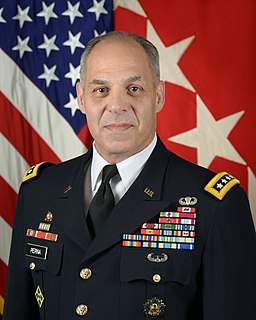

Gustave F. Perna is a United States Army four-star general who serves as the commanding general of United States Army Materiel Command. He assumed responsibilities as the 19th commanding general of the United States Army Materiel Command (AMC), headquartered at Redstone Arsenal in Alabama on September 30, 2016.