The technology of computer keyboards includes many elements. Many different keyboard technologies have been developed for consumer demands and optimized for industrial applications. The standard full-size (100%) computer alphanumeric keyboard typically uses 101 to 105 keys; keyboards integrated in laptop computers are typically less comprehensive.

A relay is an electrically operated switch. It consists of a set of input terminals for a single or multiple control signals, and a set of operating contact terminals. The switch may have any number of contacts in multiple contact forms, such as make contacts, break contacts, or combinations thereof.

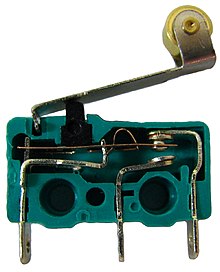

In electrical engineering, a switch is an electrical component that can disconnect or connect the conducting path in an electrical circuit, interrupting the electric current or diverting it from one conductor to another. The most common type of switch is an electromechanical device consisting of one or more sets of movable electrical contacts connected to external circuits. When a pair of contacts is touching current can pass between them, while when the contacts are separated no current can flow.

A circuit breaker is an electrical safety device designed to protect an electrical circuit from damage caused by current in excess of that which the equipment can safely carry (overcurrent). Its basic function is to interrupt current flow to protect equipment and to prevent fire. Unlike a fuse, which operates once and then must be replaced, a circuit breaker can be reset to resume normal operation.

A Hall effect sensor is any sensor incorporating one or more Hall elements, each of which produces a voltage proportional to one axial component of the magnetic field vector B using the Hall effect.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

An actuator is a component of a machine that produces force, torque, or displacement, when an electrical, pneumatic or hydraulic input is supplied to it in a system. The effect is usually produced in a controlled way. An actuator translates such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover".

A spring is a device consisting of an elastic but largely rigid material bent or molded into a form that can return into shape after being compressed or extended. Springs can store energy when compressed. In everyday use, the term most often refers to coil springs, but there are many different spring designs. Modern springs are typically manufactured from spring steel. An example of a non-metallic spring is the bow, made traditionally of flexible yew wood, which when drawn stores energy to propel an arrow.

A mercury switch is an electrical switch that opens and closes a circuit when a small amount of the liquid metal mercury connects metal electrodes to close the circuit. There are several different basic designs but they all share the common design strength of non-eroding switch contacts.

A buckling spring is a type of keyswitch mechanism, popularized by IBM's keyboards for the PC, PC/AT, 5250/3270 terminals, PS/2, and other systems. It was used by IBM's Model F keyboards, and the more common Model M. It is described in U.S. patent 4,118,611 and U.S. patent 4,528,431, both now expired. According to the original patent: "A non-teasible, snap action, tactile feedback, key mechanism of extreme mechanical simplicity and high reliability is achieved."

In electrical wiring, a light switch is a switch most commonly used to operate electric lights, permanently connected equipment, or electrical outlets. Portable lamps such as table lamps may have a light switch mounted on the socket, base, or in-line with the cord. Manually operated on/off switches may be substituted by dimmer switches that allow controlling the brightness of lamps as well as turning them on or off, time-controlled switches, occupancy-sensing switches, and remotely controlled switches and dimmers. Light switches are also found in flashlights, vehicles, and other devices.

A solenoid valve is an electromechanically operated valve.

A linear actuator is an actuator that creates linear motion, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

A pressure switch is a form of switch that operates an electrical contact when a certain set fluid pressure has been reached on its input. The switch may be designed to make contact either on pressure rise or on pressure fall. Pressure switches are widely used in industry to automatically supervise and control systems that use pressurized fluids.

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level.

Arthur William Haydon was an American inventor and industrialist known for his work in the field of microminiature electrical timing and governing devices for industrial and military use, some of which were used in early computing devices.

The Atari CX40 joystick was the first widely used cross-platform game controller. The original CX10 was released with the Atari Video Computer System in 1977 and became the primary input device for most games on the platform. The CX10 was replaced after a year by the simpler and less expensive CX40. The addition of the Atari joystick port to other platforms cemented its popularity. It was the standard for the Atari 8-bit computers and was compatible with the VIC-20, Commodore 64, Commodore 128, MSX, and later the Atari ST and Amiga. Third-party adapters allowed it to be used on other systems, such as the Apple II, Commodore 16, TI-99/4A, and the ZX Spectrum.

Cam switches are mainly used within the low voltage range. On a shaft, switching cams are made of abrasion-resistant conductive material. By rotating the shaft, the contacts are opened or closed by the cams. Often, a plurality of cams are seated on a shaft, which simultaneously switch or switch several pairs of contacts.

In engineering, a solenoid is a device that converts electrical energy to mechanical energy, using an electromagnet formed from a coil of wire. The device creates a magnetic field from electric current, and uses the magnetic field to create linear motion.

Hi-Tek Corporation was an American electronics company based in California. At first making relays, actuators, and timers in the 1960s, the company pivoted to the manufacture of keyboard assemblies and discrete keyswitches in the late 1970s. They proved successful in the keyboard business, gaining clients such as Hewlett-Packard and Texas Instruments, and were acquired by Nippon Miniature Bearing in 1983.