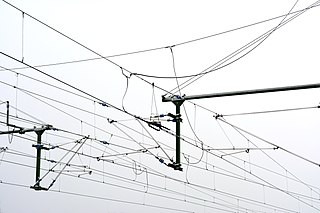

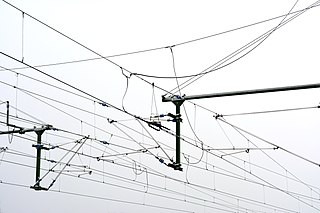

An overhead line or overhead wire is an electrical cable that is used to transmit electrical energy to electric locomotives, trolleybuses or trams. The generic term used by the International Union of Railways for the technology is overhead line. It is known variously as overhead catenary, overhead contact line (OCL), overhead contact system (OCS), overhead equipment (OHE), overhead line equipment, overhead lines (OHL), overhead wiring (OHW), traction wire, and trolley wire.

A third rail, also known as a live rail, electric rail or conductor rail, is a method of providing electric power to a railway locomotive or train, through a semi-continuous rigid conductor placed alongside or between the rails of a railway track. It is used typically in a mass transit or rapid transit system, which has alignments in its own corridors, fully or almost fully segregated from the outside environment. Third rail systems are usually supplied from direct current electricity.

An electric locomotive is a locomotive powered by electricity from overhead lines, a third rail or on-board energy storage such as a battery or a supercapacitor. Locomotives with on-board fuelled prime movers, such as diesel engines or gas turbines, are classed as diesel-electric or gas turbine-electric and not as electric locomotives, because the electric generator/motor combination serves only as a power transmission system.

Railway electrification is the use of electric power for the propulsion of rail transport. Electric railways use either electric locomotives, electric multiple units or both. Electricity is typically generated in large and relatively efficient generating stations, transmitted to the railway network and distributed to the trains. Some electric railways have their own dedicated generating stations and transmission lines, but most purchase power from an electric utility. The railway usually provides its own distribution lines, switches, and transformers.

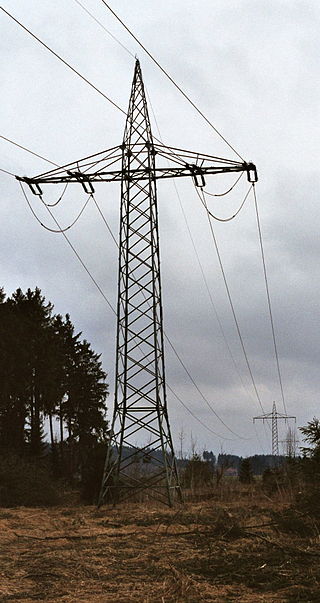

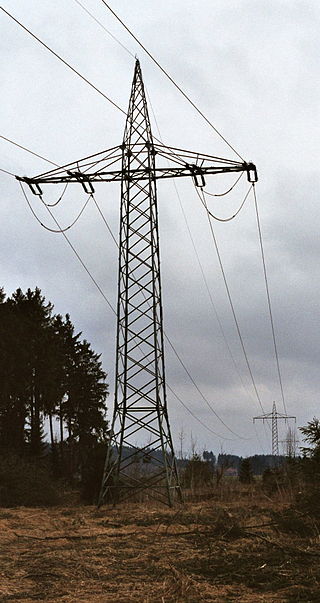

A traction network or traction power network is an electricity grid for the supply of electrified rail networks. The installation of a separate traction network generally is done only if the railway in question uses alternating current (AC) with a frequency lower than that of the national grid, such as in Germany, Austria and Switzerland.

Railway electrification systems using alternating current (AC) at 25 kilovolts (kV) are used worldwide, especially for high-speed rail. It is usually supplied at the standard utility frequency, which simplifies traction substations. The development of 25 kV AC electrification is closely connected with that of successfully using utility frequency.

Railway electrification using alternating current (AC) at 15 kilovolts (kV) and 16.7 hertz (Hz) are used on transport railways in Germany, Austria, Switzerland, Sweden, and Norway. The high voltage enables high power transmission with the lower frequency reducing the losses of the traction motors that were available at the beginning of the 20th century. Railway electrification in late 20th century tends to use 25 kV, 50 Hz AC systems which has become the preferred standard for new railway electrifications but extensions of the existing 15 kV networks are not completely unlikely. In particular, the Gotthard Base Tunnel still uses 15 kV, 16.7 Hz electrification.

In rail transport, head-end power (HEP), also known as electric train supply (ETS), is the electrical power distribution system on a passenger train. The power source, usually a locomotive at the front or 'head' of a train, provides the electricity used for heating, lighting, electrical and other 'hotel' needs. The maritime equivalent is hotel electric power. A successful attempt by the London, Brighton and South Coast Railway in October 1881 to light the passenger cars on the London to Brighton route heralded the beginning of using electricity to light trains in the world.

An electro-diesel locomotive is a type of locomotive that can be powered either from an electricity supply or by using the onboard diesel engine. For the most part, these locomotives are built to serve regional, niche markets with a very specific purpose.

An electric multiple unit (EMU) is an electric self-powered train, capable of operating in multiple with other EMUs and without the need for a locomotive; these are typically passenger trains with accommodation in every vehicle and a driving position at each end. The term can also be used to describe a train that is a permanent formation with a non-driving power car, such as the Advanced Passenger Train. As of December 2010, two-thirds of the passenger carriages in Great Britain are formed in EMUs.

Alstom Traxx is a modular product platform of mainline diesel-electric and electric locomotives produced originally by Bombardier Transportation and later Alstom, which was built in both freight and passenger variants. The first version was a dual-voltage AC locomotive built for German railways from the year 2000. Later types included DC versions, as well as quadruple-voltage machines, able to operate on most European electrification schemes: 1.5/3.0 kV DC and 15/25 kV AC. The family was expanded in 2006 to include diesel-powered versions. Elements common to all variants include steel bodyshells, two bogies with two powered axles each, three-phase asynchronous induction motors, cooling exhausts on the roof edges, and wheel disc brakes.

Railroad electrification in the United States began at the turn of the 20th century and comprised many different systems in many different geographical areas, few of which were connected. Despite this situation, these systems shared a small number of common reasons for electrification.

Railway electrification in Great Britain began in the late 19th century. A range of voltages has been used, employing both overhead lines and conductor rails. The two most common systems are 25 kV AC using overhead lines, and the 750 V DC third rail system used in Southeast England and on Merseyrail. As of March 2020, 3,758 miles (6,048 km) (38%) of the British rail network was electrified.

Railway electric traction describes the various types of locomotive and multiple units that are used on electrification systems around the world.

Amtrak's 25 Hz traction power system is a traction power network for the southern portion of the Northeast Corridor (NEC), the Keystone Corridor, and several branch lines between New York City and Washington D.C. The system was constructed by the Pennsylvania Railroad between 1915 and 1938 before the North American power transmission grid was fully established. This is the reason the system uses 25 Hz, as opposed to 60 Hz, which is the standard for power transmission in North America. In 1976, Amtrak inherited the system from Penn Central, the successor to the Pennsylvania Railroad, along with the rest of the NEC infrastructure.

Amtrak operates a 60 Hz traction power system along the Northeast Corridor between New Haven, Connecticut, and Boston, Massachusetts. This system was built in the late 1990s and supplies locomotives with power from an overhead catenary system at 25 kV alternating current with a frequency of 60 Hz. The system is also commonly known as the Northend Electrification, in contrast to the Southend Electrification that runs between New York City and Washington, D.C.

The New York, New Haven and Hartford Railroad pioneered electrification of main line railroads using high-voltage, alternating current, single-phase overhead catenary. It electrified its mainline between Stamford, Connecticut, and Woodlawn, New York, in 1907 and extended the electrification to New Haven, Connecticut, in 1914. While single-phase AC railroad electrification has become commonplace, the New Haven's system was unprecedented at the time of construction. The significance of this electrification was recognized in 1982 by its designation as a Historic Mechanical Engineering Landmark by the American Society of Mechanical Engineers (ASME).

Baldwin, the locomotive manufacturer, and Westinghouse, the promoter of AC electrification, joined forces in 1895 to develop AC railway electrification. Soon after the turn of the century, they marketed a single-phase high-voltage system to railroads. From 1904 to 1905 they supplied locomotives carrying a joint builder's plate to a number of American railroads, particularly for the New Haven line from New York to New Haven, and other New Haven lines. Westinghouse would produce the motors, controls, and other electrical gear, while Baldwin would produce the running gear, frame, body, and perform final assembly.

The Transnet Freight Rail Class 20E of 2013 is a South African electric locomotive.