Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference and identifiable chemical change. These reactions involve electrons moving via an electronically conducting phase between electrodes separated by an ionically conducting and electronically insulating electrolyte.

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit. In electrochemical cells, electrodes are essential parts that can consist of a variety of materials (chemicals) depending on the type of cell. An electrode may be called either a cathode or anode according to the direction of the electric current, unrelated to the potential difference between electrodes.

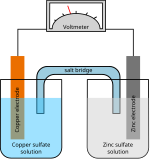

An electrochemical cell is a device that generates electrical energy from chemical reactions. Electrical energy can also be applied to these cells to cause chemical reactions to occur. Electrochemical cells that generate an electric current are called voltaic or galvanic cells and those that generate chemical reactions, via electrolysis for example, are called electrolytic cells.

In chemistry and manufacturing, electrolysis is a technique that uses direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential. The word "lysis" means to separate or break, so in terms, electrolysis would mean "breakdown via electricity."

In chemistry, a half reaction is either the oxidation or reduction reaction component of a redox reaction. A half reaction is obtained by considering the change in oxidation states of individual substances involved in the redox reaction. Often, the concept of half reactions is used to describe what occurs in an electrochemical cell, such as a Galvanic cell battery. Half reactions can be written to describe both the metal undergoing oxidation and the metal undergoing reduction.

An alkaline battery is a type of primary battery where the electrolyte has a pH value above 7. Typically these batteries derive energy from the reaction between zinc metal and manganese dioxide.

The nickel–iron battery is a rechargeable battery having nickel(III) oxide-hydroxide positive plates and iron negative plates, with an electrolyte of potassium hydroxide. The active materials are held in nickel-plated steel tubes or perforated pockets. It is a very robust battery which is tolerant of abuse, and can have very long life even if so treated. It is often used in backup situations where it can be continuously charged and can last for more than 20 years. Due to its low specific energy, poor charge retention, and high cost of manufacture, other types of rechargeable batteries have displaced the nickel–iron battery in most applications.

A zinc–air battery is a metal–air electrochemical cell powered by the oxidation of zinc with oxygen from the air. During discharge, a mass of zinc particles forms a porous anode, which is saturated with an electrolyte. Oxygen from the air reacts at the cathode and forms hydroxyl ions which migrate into the zinc paste and form zincate, releasing electrons to travel to the cathode. The zincate decays into zinc oxide and water returns to the electrolyte. The water and hydroxyl from the anode are recycled at the cathode, so the water is not consumed. The reactions produce a theoretical voltage of 1.65 Volts, but is reduced to 1.35–1.4 V in available cells.

A silver oxide battery is a primary cell using silver oxide as the cathode material and zinc for the anode. These cells maintain a nearly constant nominal voltage during discharge until fully depleted. They are available in small sizes as button cells, where the amount of silver used is minimal and not a prohibitively expensive contributor to the overall product cost.

A zinc–carbon battery (or carbon zinc battery in U.S. English) is a dry cell primary battery that provides direct electric current from the electrochemical reaction between zinc (Zn) and manganese dioxide (MnO2) in the presence of an ammonium chloride (NH4Cl) electrolyte. It produces a voltage of about 1.5 volts between the zinc anode, which is typically constructed as a cylindrical container for the battery cell, and a carbon rod surrounded by a compound with a higher Standard electrode potential (positive polarity), known as the cathode, that collects the current from the manganese dioxide electrode. The name "zinc-carbon" is slightly misleading as it implies that carbon is acting as the oxidizing agent rather than the manganese dioxide.

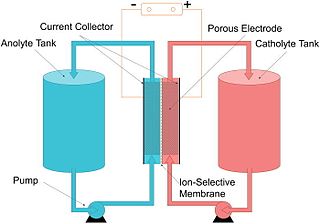

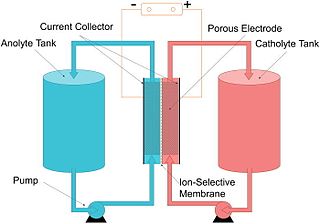

A flow battery, or redox flow battery, is a type of electrochemical cell where chemical energy is provided by two chemical components dissolved in liquids that are pumped through the system on separate sides of a membrane. Ion transfer inside the cell occurs across the membrane while the liquids circulate in their respective spaces.

A nickel–zinc battery is a type of rechargeable battery similar to nickel–cadmium batteries, but with a higher voltage of 1.6 V.

A zinc-bromine battery is a rechargeable battery system that uses the reaction between zinc metal and bromine to produce electric current, with an electrolyte composed of an aqueous solution of zinc bromide. Zinc has long been used as the negative electrode of primary cells. It is a widely available, relatively inexpensive metal. It is rather stable in contact with neutral and alkaline aqueous solutions. For this reason, it is used today in zinc–carbon and alkaline primaries.

The Leclanché cell is a battery invented and patented by the French scientist Georges Leclanché in 1866. The battery contained a conducting solution (electrolyte) of ammonium chloride, a cathode of carbon, a depolarizer of manganese dioxide (oxidizer), and an anode of zinc (reductant). The chemistry of this cell was later successfully adapted to manufacture a dry cell.

Aluminium–air batteries produce electricity from the reaction of oxygen in the air with aluminium. They have one of the highest energy densities of all batteries, but they are not widely used because of problems with high anode cost and byproduct removal when using traditional electrolytes. This has restricted their use to mainly military applications. However, an electric vehicle with aluminium batteries has the potential for up to eight times the range of a lithium-ion battery with a significantly lower total weight.

The ZEBRA battery is a type of rechargeable molten salt battery based on commonly available and low-cost materials – primarily nickel metal, the sodium and chloride from conventional table salt, as well beta-alumina solid electrolyte. It is technically known as the sodium–nickel–chloride battery, and sometimes as a sodium–metal–halide battery. The common name comes from its development under the Zeolite Battery Research Africa (ZEBRA) project, started in South Africa in 1985.

An electric battery is a source of electric power consisting of one or more electrochemical cells with external connections for powering electrical devices. When a battery is supplying power, its positive terminal is the cathode and its negative terminal is the anode. The terminal marked negative is the source of electrons. When a battery is connected to an external electric load, those negatively charged electrons flow through the circuit and reach to the positive terminal, thus cause a redox reaction by attracting positively charged ions, cations. Thus converts high-energy reactants to lower-energy products, and the free-energy difference is delivered to the external circuit as electrical energy. Historically the term "battery" specifically referred to a device composed of multiple cells; however, the usage has evolved to include devices composed of a single cell.

The lithium–air battery (Li–air) is a metal–air electrochemical cell or battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow.

A metal–air electrochemical cell is an electrochemical cell that uses an anode made from pure metal and an external cathode of ambient air, typically with an aqueous or aprotic electrolyte.

A zinc-ion battery or Zn-ion battery (abbreviated as ZIB) uses zinc ions (Zn2+) as the charge carriers. Specifically, ZIBs utilize Zn metal as the anode, Zn-intercalating materials as the cathode, and a Zn-containing electrolyte. Generally, the term zinc-ion battery is reserved for rechargeable (secondary) batteries, which are sometimes also referred to as rechargeable zinc metal batteries (RZMB). Thus, ZIBs are different than non-rechargeable (primary) batteries which use zinc, such as alkaline or zinc–carbon batteries.