A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Murrays' Mills is a complex of former cotton mills on land between Jersey Street and the Rochdale Canal in the district of Ancoats, Manchester, England. The mills were built for brothers Adam and George Murray.

Houldsworth Mill, also known as Reddish Mill, is a former mill in Reddish, Stockport, Greater Manchester, England. Designed by Abraham Stott, it was constructed in 1865 for Henry Houldsworth, a prominent mill owner at the time. It is a Grade II* listed building.

Shudehill Mill or Simpson's Mill was a very early cotton mill in Manchester city centre, England. It was built in 1782 by for Richard Arkwright and his partners and destroyed by fire in 1854. It was rebuilt and finally destroyed during the Manchester Blitz in 1940. One of Arkwright's larger mills, it was built three years before his patent lapsed. The mill had a 30 feet diameter water wheel and a Newcomen atmospheric engine was installed. Doubts remain as to why the engine was installed, whether it was a failed attempt to power a mill directly by steam or was modified to assist the wheel. It is possible that this engine, constructed by Hunt, could have been one of the 13 engines installed in Manchester mills by Joshua Wrigley. Water from the upper storage pond turned the water wheel to drive the mill. The steam engine recycled water from the lower storage pond to the upper storage pond. Three more Boulton and Watt engines were installed to power the increasing number of spindles.

Rock Mill was cotton spinning mill in the Waterloo district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1891 and 1893 for the Ashton Syndicate by Sydney Stott of Oldham. Rock Mill was built on the site of Wilshaw Mill retaining and using the octagonal chimney. It ceased spinning cotton in the 1960s and was demolished in 1971; the site became the location for the town's first Asda supermarket, which opened in 1972, until Asda relocated to a much larger new store site in Cavendish Street in 1989.

Atlas Mill was a cotton spinning mill in the Waterloo district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1898 and 1900 for the Ashton Syndicate by Sydney Stott of Oldham. It was last mill in Ashton to cease spinning. It was spinning artificial fibres in 1987, it closed in 1990 and was demolished in 1994; the site is now a housing estate.

Curzon Mill, later known as Alger Mill was a cotton spinning mill in the Hurst district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1899 and 1902 for the Ashton Syndicate by Sydney Stott of Oldham. It was a sister mill to the Atlas Mill. It was sold to the Alger Spinning Co. Ltd in 1911, and closed in 1942. It was then used as a cigarette factory by the J.A. Pattreiouex company until 1966, and then sold to the Qualitex company for the production of artificial fibres. It was still spinning artificial fibres in the 1990s and was demolished in 1994; the site being used for a housing estate.

Cedar Mill was a cotton spinning mill in the Hurst area of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1903 and 1905 for the Ashton Syndicate by Sydney Stott of Oldham. It was the last mill in Ashton spinning cotton. It ceased in 1980. It was demolished and the land was used for housing.

Cavendish Mill is a Grade II* listed former cotton spinning mill in Ashton-under-Lyne, Greater Manchester, in the United Kingdom. It was built between 1884 and 1885 for the Cavendish Spinning Company by Potts, Pickup & Dixon of Oldham. Cavendish Mill was next to the Ashton Canal Warehouse at Portland Basin. It ceased spinning cotton in 1934 and was then used for a variety of purposes before it was converted into housing in 1994.

Broadstone Mill was a double cotton spinning mill on the eastern bank of the Stockport Branch Canal in Reddish, Stockport, Greater Manchester, England. Construction of the twin mills commenced in 1903 and was completed in 1907. They closed in 1957, and the southern mill and engine houses were demolished in 1965. The northern block went into multiple usage. It is now part of the Houldsworth Village development and used as a centre for small businesses, and a shopping outlet.

Brunswick Mill, Ancoats is a former cotton spinning mill on Bradford Road in Ancoats, Manchester, England. The mill was built around 1840, part of a group of mills built along the Ashton Canal, and at that time it was one of the country's largest mills. It was built round a quadrangle, a seven-storey block facing the canal. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967.

Malta Mill, Middleton is a former cotton spinning mill in the Mills Hill area of Chadderton, Greater Manchester. It lies alongside the Rochdale Canal. It was built in 1904 as a new mule mill, by F. W. Dixon The engine stopped in 1963. The building still stands.

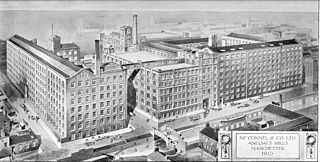

McConnel & Kennedy Mills are a group of cotton mills on Redhill Street in Ancoats, Manchester, England. With the adjoining Murrays' Mills, they form a nationally important group.

Ellenroad Mill was a cotton spinning mill in Newhey, a village in the Milnrow area of Rochdale, England. It was built as a mule spinning mill in 1890 by Stott and Sons and extended in 1899. It was destroyed by fire on 19 January 1916. When it was rebuilt, it was designed and equipped as a ring spinning mill.

Pear New Mill is a former Edwardian cotton spinning mill on the northern bank of the River Goyt in Bredbury, Stockport, Greater Manchester, England. It is a Grade II* listed building.

Barnfield Mills was a complex of cotton mills that operated in Tyldesley, Greater Manchester, England from the middle of the 19th century.

Kearsley Mill is a 240,000 sq ft (22,000 m2), late period cotton mill located in the small village of Prestolee in Kearsley, Greater Manchester, part of the historic county of Lancashire. A near complete example of Edwardian mill architecture, the building now functions as headquarters for a number of businesses and is still used in the continued manufacturing and distribution of textiles by Richard Haworth Ltd Est (1876), part of the Ruia Group. The mill is a Grade II listed building.

Victoria Mill is a Grade II* listed 19th-century cotton spinning mill in Miles Platting, Manchester, England. It was a double mill designed by George Woodhouse and completed in 1869.

Wear Mill was an integrated cotton works on the Cheadle Heath bank of the River Mersey in Stockport, Greater Manchester, in England. It was started around 1790 and added to, particularly in 1831 and 1884. In 1840, the Stockport Viaduct was built over the river and over Wear Mill.