Corundum is a crystalline form of aluminium oxide typically containing traces of iron, titanium, vanadium and chromium. It is a rock-forming mineral. It is also a naturally transparent material, but can have different colors depending on the presence of transition metal impurities in its crystalline structure. Corundum has two primary gem varieties: ruby and sapphire. Rubies are red due to the presence of chromium, and sapphires exhibit a range of colors depending on what transition metal is present. A rare type of sapphire, padparadscha sapphire, is pink-orange.

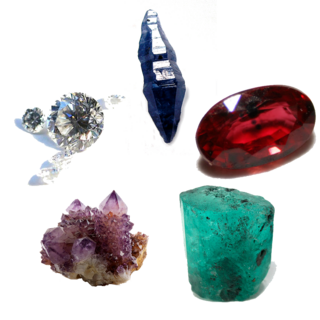

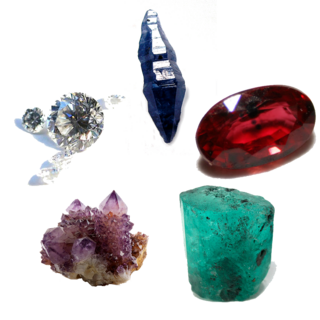

A gemstone is a piece of mineral crystal which, in cut and polished form, is used to make jewelry or other adornments. However, certain rocks and occasionally organic materials that are not minerals are also used for jewelry and are therefore often considered to be gemstones as well. Most gemstones are hard, but some soft minerals are used in jewelry because of their luster or other physical properties that have aesthetic value. Rarity is another characteristic that lends value to a gemstone.

Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminum oxide (α-Al2O3) with trace amounts of elements such as iron, titanium, chromium, vanadium, or magnesium. It is typically blue, but natural "fancy" sapphires also occur in yellow, purple, orange, and green colors; "parti sapphires" show two or more colors. The only color corundum stone that the term sapphire is not used for is red, which is called a ruby. Pink colored corundum may be either classified as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules. Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs.

A ruby is a pink to blood-red colored gemstone, a variety of the mineral corundum. Other varieties of gem-quality corundum are called sapphires. Ruby is one of the traditional cardinal gems, together with amethyst, sapphire, emerald, and diamond. The word ruby comes from ruber, Latin for red. The color of a ruby is due to the element chromium.

Strontium titanate is an oxide of strontium and titanium with the chemical formula SrTiO3. At room temperature, it is a centrosymmetric paraelectric material with a perovskite structure. At low temperatures it approaches a ferroelectric phase transition with a very large dielectric constant ~104 but remains paraelectric down to the lowest temperatures measured as a result of quantum fluctuations, making it a quantum paraelectric. It was long thought to be a wholly artificial material, until 1982 when its natural counterpart—discovered in Siberia and named tausonite—was recognised by the IMA. Tausonite remains an extremely rare mineral in nature, occurring as very tiny crystals. Its most important application has been in its synthesized form wherein it is occasionally encountered as a diamond simulant, in precision optics, in varistors, and in advanced ceramics.

Asterism, the property of a star stone (asteria), is the phenomenon of gemstones exhibiting a star-like concentration of reflected or refracted light when cut en cabochon.

A boule is a single crystal ingot produced by synthetic means.

The Bridgman–Stockbarger technique is named after Harvard physicist Percy Williams Bridgman (1882-1961) and MIT physicist Donald C. Stockbarger (1895–1952). The technique includes two similar but distinct methods primarily used for growing boules, but which can be used for solidifying polycrystalline ingots as well.

A diamond simulant, diamond imitation or imitation diamond is an object or material with gemological characteristics similar to those of a diamond. Simulants are distinct from synthetic diamonds, which are actual diamonds having the same material properties as natural diamonds. Enhanced diamonds are also excluded from this definition. A diamond simulant may be artificial, natural, or in some cases a combination thereof. While their material properties depart markedly from those of diamond, simulants have certain desired characteristics—such as dispersion and hardness—which lend themselves to imitation. Trained gemologists with appropriate equipment are able to distinguish natural and synthetic diamonds from all diamond simulants, primarily by visual inspection.

Edmond Frémy was a French chemist. He is perhaps best known today for Frémy's salt, a strong oxidizing agent which he discovered in 1845. Fremy's salt is a long-lived free radical that finds use as a standard in electron paramagnetic resonance spectroscopy.

Auguste Victor Louis Verneuil was a French chemist best known for developing a more efficient form of flame fusion, and so enabling the industrial production of synthetic gemstones. Flame-fusion had previously been used by Antoine Lavoisier to synthesize the first corundum in 1782, by Marc Gaudin to produce the first synthetic ruby in 1834, and by the unknown inventor of Geneva Rubies to produce the first large and transparent rubies in around 1886. But Verneuil increased the efficiency of the process, known today as the Verneuil process, which remains in use as an inexpensive means of making synthetic corundum.

Synthetic alexandrite is an artificially-grown variety of chrysoberyl crystal, composed of beryllium aluminum oxide (BeAl2O4). The name is also often used erroneously to describe synthetically-grown corundum.

Tairus is a synthetic gemstone manufacturer. It was formed in 1989 as part of Mikhail Gorbachev's perestroika initiative to establish a joint venture between the Russian Academy of Sciences and Tairus Created Gems Co Ltd. of Bangkok, Thailand. Today Tairus is a major supplier of hydrothermally grown gemstones to the jewellery industry. Later, Tairus became a privately held enterprise, operating out of its Bangkok distribution hub under the trade name Tairus, owned by Tairus Created Gems Co Ltd. of Bangkok, Thailand.

Marc Antoine Auguste Gaudin (1804–1880) was a French chemist.

Jacques-Joseph Ébelmen was a French chemist.

The micro-pulling-down (μ-PD) method is a crystal growth technique based on continuous transport of the melted substance through micro-channel(s) made in a crucible bottom. Continuous solidification of the melt is progressed on a liquid/solid interface positioned under the crucible. In a steady state, both the melt and the crystal are pulled-down with a constant velocity.

The Shelby Gem Factory, also known as ICT Incorporated, is a Michigan company that manufactures artificial gemstones through proprietary processes. The factory makes more varieties of man-made gemstones than any other in the world. It grows artificial gems and gem simulants, including synthetic ruby and sapphire and simulated diamonds, citrine, topaz, and other birthstone substitutes, and mounts them in gold or silver jewelry.

Golden Sheen Sapphire, is a name that is known to be associated with golden sapphire. It typically shows a metallic golden colour with translucent material also possible. It has the same color, chemical properties and features as black star sapphire.

The Kyropoulos process is a method of bulk crystal growth used to obtain single crystals. The process is named for Spyro Kyropoulos, who proposed the technique in 1926 as a method to grow brittle alkali halide and alkali earth metal crystals for precision optics.