A nuclear reactor, formerly known as an atomic pile, is a device used to initiate and control a self-sustained nuclear chain reaction. Nuclear reactors are used at nuclear power plants for electricity generation and in nuclear marine propulsion. Heat from nuclear fission is passed to a working fluid, which in turn runs through steam turbines. These either drive a ship's propellers or turn electrical generators' shafts. Nuclear generated steam in principle can be used for industrial process heat or for district heating. Some reactors are used to produce isotopes for medical and industrial use, or for production of weapons-grade plutonium. As of early 2019, the IAEA reports there are 454 nuclear power reactors and 226 nuclear research reactors in operation around the world.

Pressurized water reactors (PWRs) constitute the large majority of the world's nuclear power plants and are one of three types of light-water reactor (LWR), the other types being boiling water reactors (BWRs) and supercritical water reactors (SCWRs). In a PWR, the primary coolant (water) is pumped under high pressure to the reactor core where it is heated by the energy released by the fission of atoms. The heated water then flows to a steam generator where it transfers its thermal energy to a secondary system where steam is generated and flows to turbines which, in turn, spin an electric generator. In contrast to a boiling water reactor, pressure in the primary coolant loop prevents the water from boiling within the reactor. All LWRs use ordinary water as both coolant and neutron moderator.

An Advanced Gas-cooled Reactor (AGR) is a type of nuclear reactor designed and operated in the United Kingdom. These are the second generation of British gas-cooled reactors, using graphite as the neutron moderator and carbon dioxide as coolant. They have been the backbone of the UK's nuclear generation fleet since the 1980s.

A nuclear meltdown is a severe nuclear reactor accident that results in core damage from overheating. The term nuclear meltdown is not officially defined by the International Atomic Energy Agency or by the Nuclear Regulatory Commission. It has been defined to mean the accidental melting of the core of a nuclear reactor, however, and is in common usage a reference to the core's either complete or partial collapse.

The RBMK is a class of graphite-moderated nuclear power reactor designed and built by the Soviet Union. The name refers to its unusual design where, instead of a large steel pressure vessel surrounding the entire core, each fuel assembly is enclosed in an individual 8 cm diameter pipe which allows the flow of cooling water around the fuel.

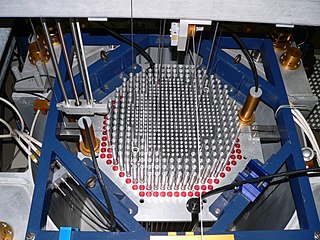

A fast-neutron reactor (FNR) or simply a fast reactor is a category of nuclear reactor in which the fission chain reaction is sustained by fast neutrons, as opposed to thermal neutrons used in thermal-neutron reactors. Such a reactor needs no neutron moderator, but requires fuel that is relatively rich in fissile material when compared to that required for a thermal-neutron reactor.

Passive nuclear safety is a design approach for safety features, implemented in a nuclear reactor, that does not require any active intervention on the part of the operator or electrical/electronic feedback in order to bring the reactor to a safe shutdown state, in the event of a particular type of emergency. Such design features tend to rely on the engineering of components such that their predicted behaviour would slow down, rather than accelerate the deterioration of the reactor state; they typically take advantage of natural forces or phenomena such as gravity, buoyancy, pressure differences, conduction or natural heat convection to accomplish safety functions without requiring an active power source. Many older common reactor designs use passive safety systems to a limited extent, rather, relying on active safety systems such as diesel powered motors. Some newer reactor designs feature more passive systems; the motivation being that they are highly reliable and reduce the cost associated with the installation and maintenance of systems that would otherwise require multiple trains of equipment and redundant safety class power supplies in order the achieve the same level of reliability. However, weak driving forces that power many passive safety features can pose significant challenges to effectiveness of a passive system, particularly in the short term following an accident.

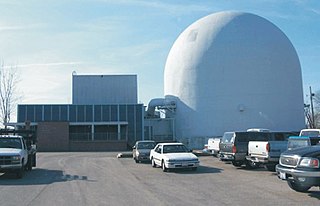

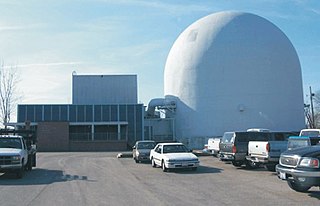

The Enrico Fermi Nuclear Generating Station is a nuclear power plant on the shore of Lake Erie near Monroe, in Frenchtown Charter Township, Michigan on approximately 1,000 acres. All units of the plant are operated by the DTE Energy Electric Company and owned by parent company DTE Energy. It is approximately halfway between Detroit, Michigan, and Toledo, Ohio. It is also visible from parts of Amherstburg and Colchester, Ontario as well as on the shore of Lake Erie in Ottawa County, Ohio along with Ohio Turnpike. Two units have been constructed on this site. The first unit's construction started on August 4, 1956 and reached initial criticality on August 23, 1963, and the second unit received its construction permit on September 26, 1972. It reached criticality in June 21, 1985 and was declared commercial on November 18, 1988. The plant is connected to two single-circuit 345 kV Transmission Lines and 3 120 kV lines. They are operated and maintained by ITC Transmission.

The Steam Generating Heavy Water Reactor (SGHWR) is a United Kingdom design for commercial nuclear reactors. It uses heavy water as the neutron moderator and normal "light" water as the coolant. The coolant boils in the reactor, like a boiling water reactor, and drives the power-extraction steam turbines.

Steam generators are heat exchangers used to convert water into steam from heat produced in a nuclear reactor core. They are used in pressurized water reactors (PWR) between the primary and secondary coolant loops.

The BN-600 reactor is a sodium-cooled fast breeder reactor, built at the Beloyarsk Nuclear Power Station, in Zarechny, Sverdlovsk Oblast, Russia. Designed to generate electrical power of 600 MW in total, the plant dispatches 560 MW to the Middle Urals power grid. It has been in operation since 1980 and represents an evolution on the preceding BN-350 reactor. In 2014, its larger sister reactor, the BN-800 reactor began operation.

The Beloyarsk Nuclear Power Station was the third of the Soviet Union's nuclear plants. It is situated by Zarechny in Sverdlovsk Oblast, Russia. Zarechny township was created to service the station, which is named after the Beloyarsky District. The closest city is Yekaterinburg.

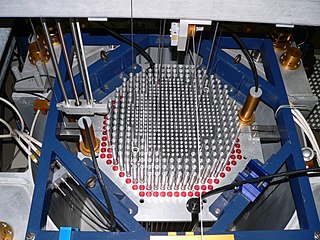

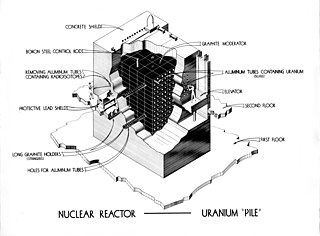

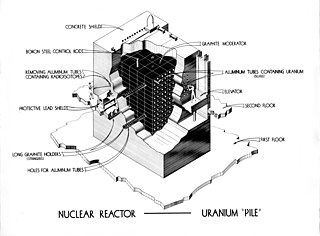

A graphite reactor is a nuclear reactor that uses carbon as a neutron moderator, which allows un-enriched uranium to be used as nuclear fuel.

Carolinas–Virginia Tube Reactor (CVTR), also known as Parr Nuclear Station, was an experimental pressurized tube heavy water nuclear power reactor at Parr, South Carolina in Fairfield County. It was built and operated by the Carolinas Virginia Nuclear Power Associates. CVTR was a small test reactor, capable of generating 17 megawatts of electricity. It was officially commissioned in December 1963 and left service in January 1967.

Obninsk Nuclear Power Plant was built in the "Science City" of Obninsk, Kaluga Oblast, about 110 km (68 mi) southwest of Moscow, Soviet Union. Connected to the power grid in June 1954, Obninsk was the first grid-connected nuclear power plant in the world, i.e. the first nuclear reactor that produced electricity industrially, albeit at small scale. It was located at the Institute of Physics and Power Engineering. The plant is also known as APS-1 Obninsk. It remained in operation between 1954 and 2002, although its production of electricity for the grid ceased in 1959; thereafter it functioned as a research and isotope production plant only.

The Sodium Reactor Experiment was a pioneering nuclear power plant built by Atomics International at the Santa Susana Field Laboratory near Simi Valley, California. The reactor operated from 1957 to 1964. On July 12, 1957 the Sodium Reactor Experiment became the first nuclear reactor in the United States to produce electrical power for a commercial power grid by powering the nearby city of Moorpark. In July 1959, the reactor experienced a partial meltdown where 13 of the reactor's 43 fuel elements partially melted, and a controlled release of radioactive gas into the atmosphere occurred. The reactor was repaired and restarted in September 1960. In February 1964, the Sodium Reactor Experiment was in operation for the last time. Removal of the deactivated reactor was completed in 1981. Technical analyses of the 1959 incident have produced contrasting conclusions regarding the types and quantities of radioactive materials released. Members of the neighboring communities have expressed concerns about the possible impacts on their health and environment from the incident. In August 2009, 50 years after the occurrence, the Department of Energy hosted a community workshop to discuss the 1959 incident.

The BN-800 reactor is a sodium-cooled fast breeder reactor, built at the Beloyarsk Nuclear Power Station, in Zarechny, Sverdlovsk Oblast, Russia. The reactor is designed to generate 880 MW of electrical power. The plant was considered part of the weapons-grade Plutonium Management and Disposition Agreement signed between the United States and Russia, with the reactor part of the final step for a plutonium-burner core. The plant reached its full power production in August, 2016. According to Russian business journal Kommersant, the BN-800 project cost 140,6 billion rubles.

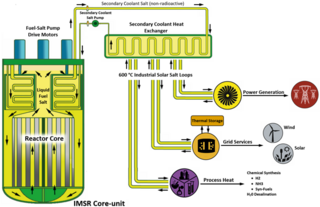

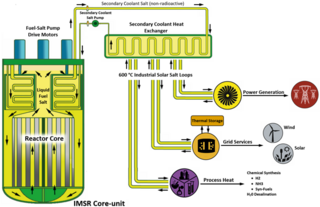

The Integral Molten Salt Reactor (IMSR) is a design for a small modular reactor (SMR) that employs molten salt reactor technology being developed by the Canadian company Terrestrial Energy. It is based closely on the denatured molten salt reactor (DMSR), a reactor design from Oak Ridge National Laboratory, and also incorporates elements found in the SmAHTR, a later design from the same laboratory. The IMSR belongs to the DMSR class of molten salt reactors (MSR) and hence is a "burner" reactor that employs a liquid fuel rather than a conventional solid fuel; this liquid contains the nuclear fuel and also serves as primary coolant.

An organic nuclear reactor, or organic cooled reactor (OCR), is a type of nuclear reactor that uses some form of organic fluid, typically a hydrocarbon substance like polychlorinated biphenyl (PCB), for cooling and sometimes as a neutron moderator as well.