A color code is a system for encoding and representing non-color information with colors to facilitate communication. This information tends to be categorical though may also be sequential.

Three-phase electric power is a common type of alternating current (AC) used in electricity generation, transmission, and distribution. It is a type of polyphase system employing three wires and is the most common method used by electrical grids worldwide to transfer power.

An electronic color code or electronic colour code is used to indicate the values or ratings of electronic components, usually for resistors, but also for capacitors, inductors, diodes and others. A separate code, the 25-pair color code, is used to identify wires in some telecommunications cables. Different codes are used for wire leads on devices such as transformers or in building wiring.

Electrical wiring in North America follows the regulations and standards applicable at the installation location. It is also designed to provide proper function, and is also influenced by history and traditions of the location installation.

IEC 60309 is a series of international standards from the International Electrotechnical Commission (IEC) for "plugs, socket-outlets and couplers for industrial purposes". They are also referred to as "pin & sleeve" connectors in North America or as "CeeForm" connectors in the entertainment industry. The maximum voltage allowed by the standard is 1000 V DC or AC; the maximum current, 800 A; and the maximum frequency, 500 Hz. The ambient temperature range is −25 °C to 40 °C.

Industrial and multiphase plugs and sockets provide a connection to the electrical mains rated at higher voltages and currents than household plugs and sockets. They are generally used in polyphase systems, with high currents, or when protection from environmental hazards is required. Industrial outlets may have weatherproof covers, waterproofing sleeves, or may be interlocked with a switch to prevent accidental disconnection of an energized plug. Some types of connectors are approved for hazardous areas such as coal mines or petrochemical plants, where flammable gas may be present.

In electric power distribution, a busbar is a metallic strip or bar, typically housed inside switchgear, panel boards, and busway enclosures for local high current power distribution. They are also used to connect high voltage equipment at electrical switchyards, and low-voltage equipment in battery banks. They are generally uninsulated, and have sufficient stiffness to be supported in air by insulated pillars. These features allow sufficient cooling of the conductors, and the ability to tap in at various points without creating a new joint.

In electrical engineering, ground and neutral are circuit conductors used in alternating current (AC) electrical systems. The neutral conductor receives and returns alternating current to the supply during normal operation of the circuit; to limit the effects of leakage current from higher-voltage systems, the neutral conductor is often connected to earth ground at the point of supply. By contrast, a ground conductor is not intended to carry current for normal operation, but instead connects exposed metallic components to earth ground. A ground conductor only carries significant current if there is a circuit fault that would otherwise energize exposed conductive parts and present a shock hazard. In that case, circuit protection devices may detect a fault to a grounded metal enclosure and automatically de-energize the circuit, or may provide a warning of a ground fault.

Electrical wiring is an electrical installation of cabling and associated devices such as switches, distribution boards, sockets, and light fittings in a structure.

Electrical wiring in the United Kingdom is commonly understood to be an electrical installation for operation by end users within domestic, commercial, industrial, and other buildings, and also in special installations and locations, such as marinas or caravan parks. It does not normally cover the transmission or distribution of electricity to them.

IEC 62056 is a set of standards for electricity metering data exchange by International Electrotechnical Commission. The IEC 62056 standards are the international standard versions of the DLMS/COSEM specification.

An earthing system or grounding system (US) connects specific parts of an electric power system with the ground, typically the equipments conductive surface, for safety and functional purposes. The choice of earthing system can affect the safety and electromagnetic compatibility of the installation. Regulations for earthing systems vary among countries, though most follow the recommendations of the International Electrotechnical Commission (IEC). Regulations may identify special cases for earthing in mines, in patient care areas, or in hazardous areas of industrial plants.

IEC 60364Electrical Installations for Buildings is the International Electrotechnical Commission (IEC)'s international standard on electrical installations of buildings. This standard is an attempt to harmonize national wiring standards in an IEC standard and is published in the European Union by CENELEC as "HD 60364". The latest versions of many European wiring regulations follow the section structure of IEC 60364 very closely, but contain additional language to cater for historic national practice and to simplify field use and determination of compliance by electricians and inspectors. National codes and site guides are meant to attain the common objectives of IEC 60364, and provide rules in a form that allows for guidance of persons installing and inspecting electrical systems.

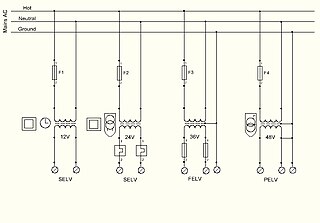

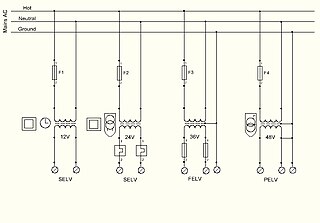

Extra-low voltage (ELV) is an electricity supply voltage and is a part of the low-voltage band in a range which carries a low risk of dangerous electrical shock. There are various standards that define extra-low voltage. The International Electrotechnical Commission (IEC) and the UK IET define an ELV device or circuit as one in which the electrical potential between two conductors or between an electrical conductor and earth (ground) does not exceed 120 volts (V) for ripple-free direct current (DC) or 50 VRMS for alternating current (AC).

NEMA connectors are power plugs and sockets used for AC mains electricity in North America and other countries that use the standards set by the US National Electrical Manufacturers Association. NEMA wiring devices are made in current ratings from 15 to 60 amperes (A), with voltage ratings from 125 to 600 volts (V). Different combinations of contact blade widths, shapes, orientations, and dimensions create non-interchangeable connectors that are unique for each combination of voltage, electric current carrying capacity, and grounding system.

An electrical code is a term for a set of regulations for the design and installation of electrical wiring in a building. The intention of such regulations is to provide standards to ensure electrical wiring systems are safe for people and property, protecting them from electrical shock and fire hazards. They are usually based on a model code produced by a national or international standards organisation.

Twin and earth cable is a colloquial name in the UK, Australia, New Zealand and other countries for a type of flat sheathed fixed mains electricity cable, containing two insulated current-carrying conductors and an Earth connector. In Australia and New Zealand this type of cable is referred to as 'Flat TPS', as well as "Twin and Earth" or "Twin with Earth".

In electrical power distribution, armoured cable usually means steel wire armoured cable (SWA) which is a hard-wearing power cable designed for the supply of mains electricity. It is one of a number of armoured electrical cables – which include 11 kV Cable and 33 kV Cable – and is found in underground systems, power networks and cable ducting.

In the process industry, chemical industry, manufacturing industry, and other commercial and industrial contexts, pipe marking is used to identify the contents, properties and flow direction of fluids in piping. It is typically carried out by marking piping through labels and color codes. Pipe marking helps personnel and fire response teams identify the correct pipes for operational, maintenance or emergency response purposes.