Computer vision tasks include methods for acquiring, processing, analyzing and understanding digital images, and extraction of high-dimensional data from the real world in order to produce numerical or symbolic information, e.g. in the forms of decisions. Understanding in this context means the transformation of visual images into descriptions of the world that make sense to thought processes and can elicit appropriate action. This image understanding can be seen as the disentangling of symbolic information from image data using models constructed with the aid of geometry, physics, statistics, and learning theory.

MEMS is the technology of microscopic devices incorporating both electronic and moving parts. MEMS are made up of components between 1 and 100 micrometres in size, and MEMS devices generally range in size from 20 micrometres to a millimetre, although components arranged in arrays can be more than 1000 mm2. They usually consist of a central unit that processes data and several components that interact with the surroundings.

Telemetry is the in situ collection of measurements or other data at remote points and their automatic transmission to receiving equipment (telecommunication) for monitoring. The word is derived from the Greek roots tele, 'remote', and metron, 'measure'. Systems that need external instructions and data to operate require the counterpart of telemetry: telecommand.

A Hall effect sensor is any sensor incorporating one or more Hall elements, each of which produces a voltage proportional to one axial component of the magnetic field vector B using the Hall effect.

Electronic stability control (ESC), also referred to as electronic stability program (ESP) or dynamic stability control (DSC), is a computerized technology that improves a vehicle's stability by detecting and reducing loss of traction (skidding). When ESC detects loss of steering control, it automatically applies the brakes to help steer the vehicle where the driver intends to go. Braking is automatically applied to wheels individually, such as the outer front wheel to counter oversteer, or the inner rear wheel to counter understeer. Some ESC systems also reduce engine power until control is regained. ESC does not improve a vehicle's cornering performance; instead, it helps reduce the chance of the driver losing control of the vehicle.

Telematics is an interdisciplinary field encompassing telecommunications, vehicular technologies, electrical engineering, and computer science. Telematics can involve any of the following:

A fieldbus is a member of a family of industrial digital communication networks used for real-time distributed control. Fieldbus profiles are standardized by the International Electrotechnical Commission (IEC) as IEC 61784/61158.

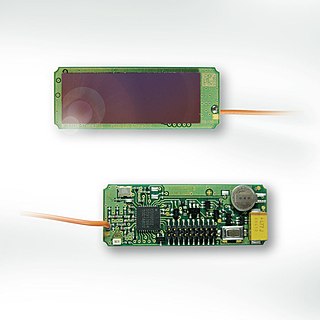

The EnOcean technology is an energy harvesting wireless technology used primarily in building automation systems, but also in other application fields such as industry, transportation, and logistics. The energy harvesting wireless modules are manufactured and marketed by the company EnOcean, headquartered in Oberhaching near Munich. The modules combine micro energy converters with ultra low power electronics and wireless communications and enable batteryless, wireless sensors, switches, and controls.

An engine control unit (ECU), also called an engine control module (ECM), is a device which controls multiple systems of an internal combustion engine in a single unit. Systems commonly controlled by an ECU include the fuel injection and ignition systems.

Actuator Sensor Interface is an industrial networking solution used in PLC, DCS and PC-based automation systems. It is designed for connecting simple field I/O devices in discrete manufacturing and process applications using a single two-conductor cable.

SAMSON AG, founded in 1907 by Hermann Sandvoss, is a German corporation headquartered in Frankfurt. It develops systems and products that can control all types of fluid. Its product line includes valves, self-operating regulators, automation systems, sensors, thermostats, and digital devices, among others.

Parking sensors are proximity sensors for road vehicles designed to alert the driver of obstacles while parking. These systems use either electromagnetic or ultrasonic sensors.

Digital Addressable Lighting Interface (DALI) is a trademark for network-based products that control lighting. The underlying technology was established by a consortium of lighting equipment manufacturers as a successor for 1-10 V/0–10 V lighting control systems, and as an open standard alternative to several proprietary protocols. The DALI, DALI-2 and D4i trademarks are owned by the lighting industry alliance, DiiA.

Dust Networks, Inc. is an American company that specializes in the design and manufacture of wireless sensor networks for industrial applications including process monitoring, condition monitoring, asset management, environment, health and safety (EHS) monitoring, and power management. They were acquired by Linear Technology, Inc in December 2011, which in turn was acquired by Analog Devices, Inc. in 2017. The Dust Networks product team operates in the IoT Networking Platforms group of Analog Devices.

The Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) is a research institute, which is a member of the Gottfried Wilhelm Leibniz Scientific Community. The institute is located in Berlin at the Wissenschafts- und Wirtschaftsstandort Adlershof (WISTA), its research activity is applied science in the fields of III-V electronics, photonics, integrated quantum technology and III-V technology

An inertial navigation system is a navigation device that uses motion sensors (accelerometers), rotation sensors (gyroscopes) and a computer to continuously calculate by dead reckoning the position, the orientation, and the velocity of a moving object without the need for external references. Often the inertial sensors are supplemented by a barometric altimeter and sometimes by magnetic sensors (magnetometers) and/or speed measuring devices. INSs are used on mobile robots and on vehicles such as ships, aircraft, submarines, guided missiles, and spacecraft. Older INS systems generally used an inertial platform as their mounting point to the vehicle and the terms are sometimes considered synonymous.

Phoenix Contact, headquartered in Blomberg, Ostwestfalen-Lippe, Germany, is a manufacturer of industrial automation, interconnection, and interface solutions. The company develops terminal blocks, relays, connectors, signal conditioners, power supplies, controllers & PLCs, I/O systems, Industrial Ethernet, controller system cabling, PCB terminal blocks & connectors, and surge suppression. In addition, Phoenix Contact manufactures products for use with Modbus, DeviceNet, EtherNet/IP, CANopen, PROFIBUS and PROFINET networks.

The open source BiSS interface (bidirectional/serial/synchronous) is based on a protocol which implements a real time interface. It enables a secure serial digital communication between controller, sensor and actuator. The BiSS protocol is designed in B mode and C mode. It is used in industrial applications which require transfer rates, safety, flexibility and a minimized implementation effort. The BiSS interface has roots in SSI and a simplified INTERBUS. The proprietary standards, Hiperface and EnDat are competing solutions.

The industrial internet of things (IIoT) refers to interconnected sensors, instruments, and other devices networked together with computers' industrial applications, including manufacturing and energy management. This connectivity allows for data collection, exchange, and analysis, potentially facilitating improvements in productivity and efficiency as well as other economic benefits. The IIoT is an evolution of a distributed control system (DCS) that allows for a higher degree of automation by using cloud computing to refine and optimize the process controls.

IO-Link is a short distance, bi-directional, digital, point-to-point, wired, industrial communications networking standard used for connecting digital sensors and actuators to either a type of industrial fieldbus or a type of industrial Ethernet. Its objective is to provide a technological platform that enables the development and use of sensors and actuators that can produce and consume enriched sets of data that in turn can be used for economically optimizing industrial automated processes and operations. The technology standard is managed by the industry association Profibus and Profinet International.