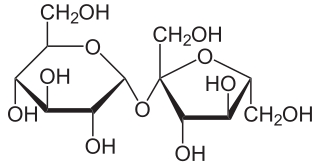

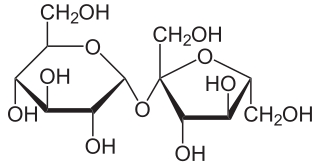

Sugar is the generic name for sweet-tasting, soluble carbohydrates, many of which are used in food. Simple sugars, also called monosaccharides, include glucose, fructose, and galactose. Compound sugars, also called disaccharides or double sugars, are molecules made of two bonded monosaccharides; common examples are sucrose, lactose, and maltose. White sugar is a refined form of sucrose. In the body, compound sugars are hydrolysed into simple sugars.

Sucrose, a disaccharide, is a sugar composed of glucose and fructose subunits. It is produced naturally in plants and is the main constituent of white sugar. It has the molecular formula C

12H

22O

11.

Molasses is a viscous byproduct, principally obtained from the refining of sugarcane or sugar beet juice into sugar. Molasses varies in the amount of sugar, the method of extraction and age of the plant. Sugarcane molasses is usually used to sweeten and flavour foods. Molasses is a major constituent of fine commercial brown sugar.

In cooking, syrup is a condiment that is a thick, viscous liquid consisting primarily of a solution of sugar in water, containing a large amount of dissolved sugars but showing little tendency to deposit crystals. In its concentrated form, its consistency is similar to that of molasses. The viscosity arises from the multiple hydrogen bonds between the dissolved sugar, which has many hydroxyl (OH) groups.

A refinery is a production facility composed of a group of chemical engineering unit processes and unit operations refining certain materials or converting raw material into products of value.

Jaggery is a traditional non-centrifugal cane sugar consumed in the Indian subcontinent, Southeast Asia, North America, Central America, Brazil and Africa. It is a concentrated product of cane juice and often date or palm sap without separation of the molasses and crystals, and can vary from golden brown to dark brown in colour. It contains up to 50% sucrose, up to 20% invert sugars, and up to 20% moisture, with the remainder made up of other insoluble matter, such as wood ash, proteins, and bagasse fibres. Jaggery is very similar to muscovado, an important sweetener in Portuguese, British and French cuisine. The Kenyan Sukari ngutu/nguru has no fibre; it is dark and is made from sugarcane and also sometimes extracted from palm tree.

Brown sugar is a sucrose sugar product with a distinctive brown color due to the presence of molasses. It is by tradition an unrefined or partially refined soft sugar consisting of sugar crystals with some residual molasses content, but is now often produced by the addition of molasses to refined white sugar.

Panela or rapadura is an unrefined whole cane sugar, typical of Latin America. It is a solid form of sucrose derived from the boiling and evaporation of sugarcane juice. Panela is known by other names in Latin America, such as chancaca in Chile, Bolivia, and Peru, piloncillo in Mexico. Just like brown sugar, two varieties of piloncillo are available; one is lighter and one darker (oscuro). Unrefined, it is commonly used in Mexico, where it has been around for at least 500 years. Made from crushed sugar cane, the juice is collected, boiled, and poured into molds, where it hardens into blocks. It is similar to jaggery, which is used in South Asia. Both are considered non-centrifugal cane sugars.

Muscovado is a type of partially refined to unrefined sugar with a strong molasses content and flavour, and dark brown in colour. It is technically considered either a non-centrifugal cane sugar or a centrifuged, partially refined sugar according to the process used by the manufacturer. Muscovado contains higher levels of various minerals than processed white sugar, and is considered by some to be healthier. Its main uses are in food and confectionery, and the manufacturing of rum and other forms of alcohol. The largest producer and consumer of muscovado is India.

High-fructose corn syrup (HFCS), also known as glucose–fructose, isoglucose and glucose–fructose syrup, is a sweetener made from corn starch. As in the production of conventional corn syrup, the starch is broken down into glucose by enzymes. To make HFCS, the corn syrup is further processed by D-xylose isomerase to convert some of its glucose into fructose. HFCS was first marketed in the early 1970s by the Clinton Corn Processing Company, together with the Japanese Agency of Industrial Science and Technology, where the enzyme was discovered in 1965.

Sugarcane juice is the liquid extracted from pressed sugarcane. It is consumed as a beverage in many places, especially where sugarcane is commercially grown, such as Southeast Asia, the Indian subcontinent, North Africa, mainly Egypt, and also in South America. Sugarcane juice is obtained by crushing peeled sugarcane in a mill and is one of the main precursors of rum.

Agriculture in Colombia refers to all agricultural activities, essential to food, feed, and fiber production, including all techniques for raising and processing livestock within the Republic of Colombia. Plant cultivation and livestock production have continuously abandoned subsistence agricultural practices in favour of technological farming resulting in cash crops which contribute to the economy of Colombia. The Colombian agricultural production has significant gaps in domestic and/or international human and animal sustenance needs.

Sugarcane or sugar cane is a species of tall, perennial grass that is used for sugar production. The plants are 2–6 m (6–20 ft) tall with stout, jointed, fibrous stalks that are rich in sucrose, which accumulates in the stalk internodes. Sugarcanes belong to the grass family, Poaceae, an economically important flowering plant family that includes maize, wheat, rice, and sorghum, and many forage crops. It is native to the warm temperate and tropical regions of India, Southeast Asia, and New Guinea.

The history of sugar has five main phases:

- The extraction of sugar cane juice from the sugarcane plant, and the subsequent domestication of the plant in tropical India and Southeast Asia sometime around 4,000 BC.

- The invention of manufacture of cane sugar granules from sugarcane juice in India a little over two thousand years ago, followed by improvements in refining the crystal granules in India in the early centuries AD.

- The spread of cultivation and manufacture of cane sugar to the medieval Islamic world together with some improvements in production methods.

- The spread of cultivation and manufacture of cane sugar to the West Indies and tropical parts of the Americas beginning in the 16th century, followed by more intensive improvements in production in the 17th through 19th centuries in that part of the world.

- The development of beet sugar, high-fructose corn syrup and other sweeteners in the 19th and 20th centuries.

Wasanbon (和三盆) is a fine-grained Japanese sugar, traditionally made in the Shikoku prefectures of Tokushima and Kagawa, centered to the towns of Kamiita-cho and Donari-cho in Tokushima, where it has been made since about the 1770s. The sugar is often used for Japanese sweets. The sugar is made from thin sugarcane plants grown locally in Shikoku, called taketō (竹糖) or chikusha (竹蔗).

A sugar cane mill is a factory that processes sugar cane to produce raw sugar or plantation white sugar. Some sugar mills are situated next to a back-end refinery, that turns raw sugar into (refined) white sugar.

The sugar industry of the United States produces sugarcane and sugar beets, operates sugar refineries, and produces and markets refined sugars, sugar-sweetened goods, and other products. The United States is among the world's largest sugar producers. Unlike most other sugar producing countries, the United States has both large and well-developed sugarcane and sugar beet industries. Refined sugarcane, processed sugar beet, and high-fructose corn syrup are all commonly used in the U.S. as added sugars to sweeten food and beverages.