Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair. A die is used to cut or form the male portion of the mating pair. The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading.

The Unified Thread Standard (UTS) defines a standard thread form and series—along with allowances, tolerances, and designations—for screw threads commonly used in the United States and Canada. It is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries. It has the same 60° profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread were chosen as an inch fraction rather than a millimeter value. The UTS is currently controlled by ASME/ANSI in the United States.

American National Standard Pipe Thread standards, often called national pipe thread standards for short, are United States national technical standards for screw threads used on threaded pipes and pipe fittings. They include both tapered and straight thread series for various purposes, including rigidity, pressure-tight sealing, or both. The types are named with a full name and an abbreviation, such as NPT, NPS, NPTF, or NPSC.

A collet is a segmented sleeve, band or collar. One of the two radial surfaces of a collet is usually tapered and the other is cylindrical. The term collet commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool, but collets have other mechanical applications.

A screw thread is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener.

A linear actuator is an actuator that creates linear motion, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

A jackscrew, or screw jack, is a type of jack that is operated by turning a leadscrew. It is commonly used to lift moderate and heavy weights, such as vehicles; to raise and lower the horizontal stabilizers of aircraft; and as adjustable supports for heavy loads, such as the foundations of houses.

A leadscrew, also known as a power screw or translation screw, is a screw used as a linkage in a machine, to translate turning motion into linear motion. Because of the large area of sliding contact between their male and female members, screw threads have larger frictional energy losses compared to other linkages. They are not typically used to carry high power, but more for intermittent use in low power actuator and positioner mechanisms. Leadscrews are commonly used in linear actuators, machine slides, vises, presses, and jacks. Leadscrews are a common component in electric linear actuators.

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for high-precision applications. The ball assembly acts as the nut while the threaded shaft is the screw.

The screw is a mechanism that converts rotational motion to linear motion, and a torque to a linear force. It is one of the six classical simple machines. The most common form consists of a cylindrical shaft with helical grooves or ridges called threads around the outside. The screw passes through a hole in another object or medium, with threads on the inside of the hole that mesh with the screw's threads. When the shaft of the screw is rotated relative to the stationary threads, the screw moves along its axis relative to the medium surrounding it; for example rotating a wood screw forces it into wood. In screw mechanisms, either the screw shaft can rotate through a threaded hole in a stationary object, or a threaded collar such as a nut can rotate around a stationary screw shaft. Geometrically, a screw can be viewed as a narrow inclined plane wrapped around a cylinder.

The ISO metric screw thread is the most commonly used type of general-purpose screw thread worldwide. They were one of the first international standards agreed when the International Organization for Standardization (ISO) was set up in 1947.

Buttress thread forms, also known as sawtooth thread forms or breech-lock thread forms. are screw thread profiles with an asymmetric shape, having one square face and the other slanted. They are most commonly used for leadscrews where the load is principally applied in one direction. The asymmetric thread form allows the thread to have low friction and withstand greater loads than other forms in one direction, but at the cost of higher friction and inferior load bearing in the opposite direction. They are typically easier to manufacture than square thread forms but offer higher load capacity than equivalently sized trapezoidal thread forms.

In mechanical engineering, backlash, sometimes called lash, play, or slop, is a clearance or lost motion in a mechanism caused by gaps between the parts. It can be defined as "the maximum distance or angle through which any part of a mechanical system may be moved in one direction without applying appreciable force or motion to the next part in mechanical sequence."p. 1-8 An example, in the context of gears and gear trains, is the amount of clearance between mated gear teeth. It can be seen when the direction of movement is reversed and the slack or lost motion is taken up before the reversal of motion is complete. It can be heard from the railway couplings when a train reverses direction. Another example is in a valve train with mechanical tappets, where a certain range of lash is necessary for the valves to work properly.

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a nut.

The square thread form is a common screw thread profile, used in high load applications such as leadscrews and jackscrews. It gets its name from the square cross-section of the thread. It is the lowest friction and most efficient thread form, but it is difficult to fabricate.

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods ; deformative or transformative methods ; additive methods ; or combinations thereof.

A roller screw, also known as a planetary roller screw or satellite roller screw, is a low-friction precision screw-type actuator, a mechanical device for converting rotational motion to linear motion, or vice versa. Planetary roller screws are used as the actuating mechanism in many electromechanical linear actuators. Due to its complexity, the roller screw is a relatively expensive actuator, but may be suitable for high-precision, high-speed, heavy-load, long-life, and heavy-use applications.

Machine element or hardware refers to an elementary component of a machine. These elements consist of three basic types:

- structural components such as frame members, bearings, axles, splines, fasteners, seals, and lubricants,

- mechanisms that control movement in various ways such as gear trains, belt or chain drives, linkages, cam and follower systems, including brakes and clutches, and

- control components such as buttons, switches, indicators, sensors, actuators and computer controllers.

A bolt is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread.

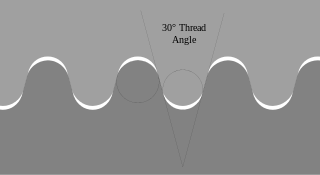

Knuckle threads or round threads are an unusual highly rounded thread form. The large space between the rounded crests and roots provides space for debris to be shifted to not interfere with the thread, making this form resistant to debris and thread damage.