Related Research Articles

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses. Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue.

Velvet is a type of woven tufted fabric in which the cut threads are evenly distributed, with a short, dense pile, giving it a distinctive soft feel. By extension, the word velvety means "smooth like velvet". In the past, velvet was typically made from silk. Today, velvet can be made from linen, cotton, wool and synthetic fibers.

A satin weave is a type of fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamental types of textile weaves alongside plain weave and twill weave.

Balbriggan is a coastal town in Fingal, in the northern part of the traditional County Dublin, Ireland. It is approximately 34 km north of the city of Dublin, for which it is a commuter town. The 2022 census population was 24,322 for Balbriggan and its environs, the 17th largest urban area in Ireland. The town formerly had an active textile industry, and was the site of a major episode in the Irish War of Independence.

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between the dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile.

Chino cloth is a twill fabric, originally made of 100% cotton. The most common items made from it, trousers, are widely called chinos. Today it is also found in cotton-synthetic blends.

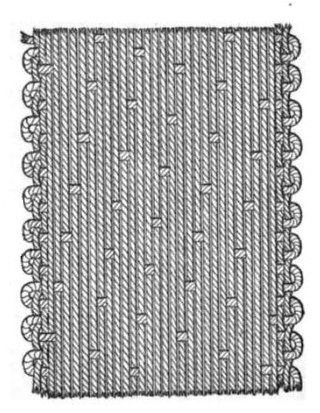

Piqué, or marcella, refers to a weaving style, normally used with cotton yarn, which is characterized by raised parallel cords or geometric designs in the fabric. Piqué fabrics vary from semi-sheer dimity to heavy weight waffle cloth. Twilled cotton and corded cotton are close relatives.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

A staple fiber is a textile fiber of discrete length. The opposite is a filament fiber, which comes in continuous lengths. Staple length is a characteristic fiber length of a sample of staple fibers. A fiber is made up of natural substances and is known for being longer than it is wide. It is an essential criterion in yarn spinning, and aids in cohesion and twisting. Compared to synthetic fibers, natural fibers tend to have different and shorter lengths. The quality of natural fibers like cotton is categorized into staple length such as short, medium, long staple, and extra-long. Gossypium barbadense, one of several cotton species, produces extra-long staple fibers. The staple fibers may be obtained from natural and synthetic sources. In the case of synthetics and blends, the filament yarns are cut to a predetermined length.

Decatising or decatizing, also known as crabbing, blowing, and decating, is the process of making permanent a textile finish on a cloth, so that it does not shrink during garment making. The word comes from the French décatir, which means to remove the cati or finish of the wool. Though used mainly for wool, the term is also applied to processes performed on fabrics of other fibers, such as cotton, linen or polyester. Crabbing and blowing are minor variations on the general process for wool, which is to roll the cloth onto a roller and blow steam through it.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Jersey is a knit fabric used predominantly for clothing manufacture. It was originally made of wool, but is now made of wool, cotton and synthetic fibers.

A pill, colloquially known as a bobble, fuzzball, or lint ball, is a small ball of fibers that forms on a piece of cloth. Pill is also a verb for the formation of such balls.

Dimensional stability pertains to a fabric's ability to maintain its initial size and shape even after undergoing wear and care, which is a desirable property. Dimension stability in fabrics or Shrinkage is the change of dimensions in textile products when they are washed or relaxed. The change is always expressed relative to the dimensions before the exposure of washing or relaxing. Shrinkage is also called residual shrinkage and measured in percentage. The major cause of shrinkages is the release of stresses and strains introduced in manufacturing processes. Textile manufacturing is based on the conversion of fiber into yarn, yarn into fabric, includes spinning, weaving, or knitting, etc. The fabric passes through many inevitable changes and mechanical forces during this journey. When the products are immersed in water, the water acts as a relaxing medium, and all stresses and strains are relaxed and the fabric tries to come back to its original state.

Piece goods were the textile materials sold in cut pieces as per the buyer's specification. The piece goods were either cut from a fabric roll or produced with a certain length, also called yard goods. Various textiles such as cotton, wool, silk, etc., were traded in terms of piece goods. The prices were determined as per the fabric quality.

Mashru is a woven cloth that is a blend of silk and cotton. It was historically a hand-woven satin silk fabric variety found in the Indian subcontinent, and its proper use is described in the 16th-century Ain-i-Akbari.

Greige goods are loom state woven fabrics, or unprocessed knitted fabrics. Greige goods undergo many subsequent processes, for instance, dyeing, printing, bleaching, and finishing, prior to further converting to finished goods such as clothing, or other textile products. "Grey fabrics" is another term to refer to unfinished woven or knitted fabrics.

Barré is an unintentional repetitive horizontal pattern in fabrics that is generally undesirable and considered as a defect. It appears as a lateral stripe pattern. Barré occurs for many reasons associated with the manufacturing of textile ensembles like fiber, yarn, fabric manufacturing, weaving or knitting, or finishing faults.

Compaction (compacting) is a finishing process used to minimize shrinking in textiles. Textile products that are loosely woven or knitted shrink more, whereas tightly knitted and woven products are more stable. The structure of knitted fabrics is competitively loose and flexible. Compaction, like sanforization for woven fabric, is intended to reduce shrinkage in tube and open width Knitted textiles.

References

- 1 2 Tortora, Phyllis G.; Johnson, Ingrid (2013-09-17). The Fairchild Books Dictionary of Textiles. A&C Black. p. 39. ISBN 978-1-60901-535-0.

- ↑ Picken, Mary Brooks (2013-07-24). A Dictionary of Costume and Fashion: Historic and Modern. Courier Corporation. pp. 12, 13. ISBN 978-0-486-14160-2.

- ↑ Garrison, Webb (1955). What's in a Word. Harper Collins. p. 174. ISBN 978-1-4185-5780-5.

- ↑ Maitra, K. K. (2007-11-15). Encyclopaedic Dictionary of Clothing and Textiles. Mittal Publications. p. 22. ISBN 978-81-8324-205-9.

- ↑ Work Materials ... National Recovery Administration. 1936. p. 186.

- 1 2 MATHEWS, KOLANJIKOMBIL (2017). Encyclopaedic Dictionary of Textile Terms: Four Volume Set. Woodhead Publishing India PVT. Limited. p. 110. ISBN 978-93-85059-66-7.

- ↑ Hollen, Norma Rosamond (1979). Textiles. Internet Archive. New York : Macmillan. p. 309. ISBN 978-0-02-356130-6.