A diesel locomotive is a type of railway locomotive in which the power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. The most common are diesel-electric locomotives and diesel-hydraulic.

Vehicle emissions control is the study of reducing the emissions produced by motor vehicles, especially internal combustion engines.

Emission standards are the legal requirements governing air pollutants released into the atmosphere. Emission standards set quantitative limits on the permissible amount of specific air pollutants that may be released from specific sources over specific timeframes. They are generally designed to achieve air quality standards and to protect human life. Different regions and countries have different standards for vehicle emissions.

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, or coal. According to the type of engine, it is discharged into the atmosphere through an exhaust pipe, flue gas stack, or propelling nozzle. It often disperses downwind in a pattern called an exhaust plume.

The BMW E70 is the second-generation BMW X5 mid-size luxury SUV. It replaced the BMW X5 (E53) in July 2006. It was manufactured alongside the BMW X6 at BMW's Greer, South Carolina plant in the U.S. and BMW's facility in Toluca, Mexico.

Lean-burn refers to the burning of fuel with an excess of air in an internal combustion engine. In lean-burn engines the air–fuel ratio may be as lean as 65:1. The air / fuel ratio needed to stoichiometrically combust gasoline, by contrast, is 14.64:1. The excess of air in a lean-burn engine emits far less hydrocarbons. High air–fuel ratios can also be used to reduce losses caused by other engine power management systems such as throttling losses.

The New European Driving Cycle (NEDC) was a driving cycle, last updated in 1997, designed to assess the emission levels of car engines and fuel economy in passenger cars. It is also referred to as MVEG cycle.

A driving cycle is a series of data points representing the speed of a vehicle versus time.

The European emission standards are vehicle emission standards for pollution from the use of new land surface vehicles sold in the European Union and European Economic Area member states and the United Kingdom, and ships in EU waters. The standards are defined in a series of European Union directives staging the progressive introduction of increasingly stringent standards.

A diesel particulate filter (DPF) is a device designed to remove diesel particulate matter or soot from the exhaust gas of a diesel engine.

The fuel economy of an automobile relates to the distance traveled by a vehicle and the amount of fuel consumed. Consumption can be expressed in terms of the volume of fuel to travel a distance, or the distance traveled per unit volume of fuel consumed. Since fuel consumption of vehicles is a significant factor in air pollution, and since the importation of motor fuel can be a large part of a nation's foreign trade, many countries impose requirements for fuel economy. Different methods are used to approximate the actual performance of the vehicle. The energy in fuel is required to overcome various losses encountered while propelling the vehicle, and in providing power to vehicle systems such as ignition or air conditioning. Various strategies can be employed to reduce losses at each of the conversions between the chemical energy in the fuel and the kinetic energy of the vehicle. Driver behavior can affect fuel economy; maneuvers such as sudden acceleration and heavy braking waste energy.

An engine test stand is a facility used to develop, characterize and test engines. The facility, often offered as a product to automotive OEMs, allows engine operation in different operating regimes and offers measurement of several physical variables associated with the engine operation.

A portable emissions measurement system (PEMS) is a vehicle emissions testing device that is small and light enough to be carried inside or moved with a motor vehicle that is being driven during testing, rather than on the stationary rollers of a dynamometer that only simulates real-world driving.

United States vehicle emission standards are set through a combination of legislative mandates enacted by Congress through Clean Air Act (CAA) amendments from 1970 onwards, and executive regulations managed nationally by the Environmental Protection Agency (EPA), and more recently along with the National Highway Traffic Safety Administration (NHTSA). These standard cover common motor vehicle air pollution, including carbon monoxide, nitrogen oxides, and particulate emissions, and newer versions have incorporated fuel economy standards.

The Diesel Emissions Reduction Act, or DERA, is a part of the Energy Policy Act of 2005. The law appropriated funds to federal and state loan programs to either rebuild diesel-powered vehicle engines to more stringent emission standards or install emission reduction systems, notify affected parties, and share the technological information with countries that have poor air quality standards.

Bharat stage emission standards (BSES) are emission standards instituted by the Government of India to regulate the output of air pollutants from compression ignition engines and Spark-ignition engines equipment, including motor vehicles. The standards and the timeline for implementation are set by the Central Pollution Control Board under the Ministry of Environment, Forest and Climate Change.

Mobile source air pollution includes any air pollution emitted by motor vehicles, airplanes, locomotives, and other engines and equipment that can be moved from one location to another. Many of these pollutants contribute to environmental degradation and have negative effects on human health. To prevent unnecessary damage to human health and the environment, environmental regulatory agencies such as the U.S. Environmental Protection Agency have established policies to minimize air pollution from mobile sources. Similar agencies exist at the state level. Due to the large number of mobile sources of air pollution, and their ability to move from one location to another, mobile sources are regulated differently from stationary sources, such as power plants. Instead of monitoring individual emitters, such as an individual vehicle, mobile sources are often regulated more broadly through design and fuel standards. Examples of this include corporate average fuel economy standards and laws that ban leaded gasoline in the United States. The increase in the number of motor vehicles driven in the U.S. has made efforts to limit mobile source pollution challenging. As a result, there have been a number of different regulatory instruments implemented to reach the desired emissions goals.

The Worldwide harmonized Light vehicles Test Procedure (WLTP) is a global standard for determining the levels of pollutants, CO2 emissions and fuel consumption of traditional and hybrid cars, as well as the range of fully electric vehicles.

A defeat device is any motor vehicle hardware, software, or design that interferes with or disables emissions controls under real-world driving conditions, even if the vehicle passes formal emissions testing. The term appears in the US Clean Air Act and European Union regulations, to describe anything that prevents an emissions control system from working, and applies as well to power plants or other air pollution sources, as to automobiles.

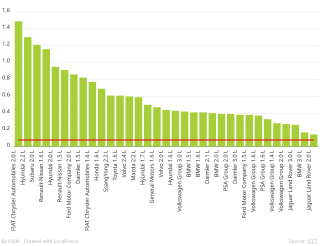

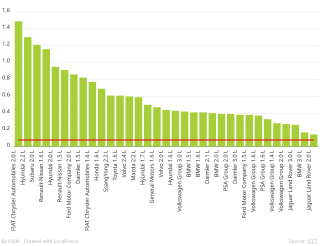

From 2014 onwards, software which manipulated air pollution tests was discovered in vehicles from some car makers; the software recognized when the standardized emissions test was being done, and adjusted the engine to emit less during the test. The cars emitted much higher levels of pollution under real-world driving conditions. Some cars' emissions were higher even though there was no manipulated software.