The examples and perspective in this article deal primarily with the United States and do not represent a worldwide view of the subject.(August 2024) |

| Resin Identification Code | |

|---|---|

| Standard Practice for Coding Plastic Manufactured Articles for Resin Identification | |

The symbol "01 PET" indicating polyethylene terephthalate, commonly used in plastic water and soda bottles. | |

| Year started | 1988 |

| Organization |

|

| Website | D7611/D7611M-21 |

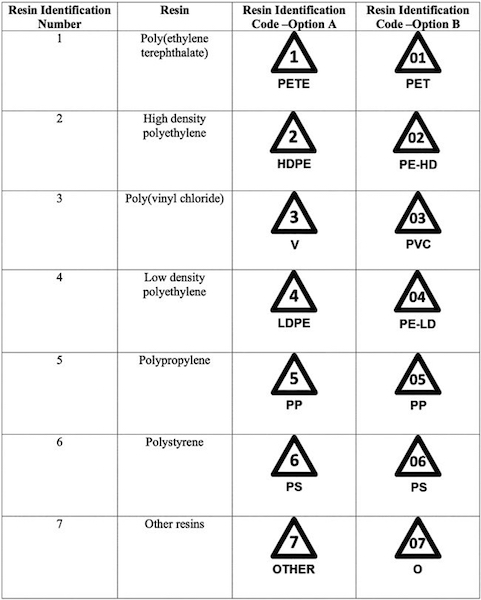

A resin identification code (RIC) is a symbol embedded on plastic products, used to sort plastic waste for recycling. They consist of a triangle of clockwise "chasing arrows", around a number indicating what type of resin it is made of (01 for PET, 02 for HDPE, 03 for PVC, 04 for LDPE, 05 for polypropylene, 06 for polystyrene, or 07 for Other).

Contents

These symbols were originally created in 1988 by the Plastics Industry Association in the United States, amid growing concerns about plastic pollution. [1] Since 2008, they are administrated by the ASTM and comprise the technical standard D7611/D7611M-21 "Standard Practice for Coding Plastic Manufactured Articles for Resin Identification". [2] The European Commission Decision 97/129/EC "Identification System For Packaging Materials" extends this system with recycling codes for other materials like batteries, paper, and glass. [3]

Despite their similarity to the recycling symbol, resin codes do not indicate whether a product is recyclable. [1] They are frequently misinterpreted by consumers, and contribute to wishcycling (the contamination of recycling bins with unrecyclable goods). [1] [4] At the US Environmental Protection Agency's recommendation, a 2013 revision to the ASTM standard replaced the "chasing arrows" with a solid equilateral triangle, but the old symbols are still more widely used among manufacturers.