| |

Location in Greater Manchester | |

| Cotton | |

|---|---|

| Spinning (Mule mill) | |

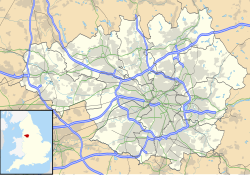

| Location | Ashton-under-Lyne, Greater Manchester, England |

| Serving railway | Lancashire and Yorkshire Railway |

| Owner | Rock mill Spinning Company |

| Further ownership |

|

| Current owners | Site of Superstore |

| Coordinates | 53°29′54″N2°06′07″W / 53.4983°N 2.1020°W |

| Construction | |

| Built | February 1891 |

| Completed | August 1893 |

| Demolished | 1971 |

| Floor count | 4 |

| Main contractor | E. & J. Smethurst |

| Design team | |

| Architect | Sydney Stott of Oldham |

| Power | |

| Date | 1892 |

| Engine maker | George Saxon & Co |

| Engine type | Triple expansion, 4 cylinder |

| Valve Gear | Corliss |

| Cylinder diameter and throw | 6ft |

| rpm | 75 |

| Installed horse power (ihp) | 1250 |

| Flywheel diameter | 16ft |

| Boiler configuration | |

| Boilers | Fernihough and Son, Dukinfield |

| Pressure | 120 |

| Equipment | |

| Mule Frames | 66000 spindles (1894) 74,186 spindles (1911) |

| References | |

| Haynes 1987, p. 49 | |

Rock Mill was cotton spinning mill in the Waterloo district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1891 and 1893 for the Ashton Syndicate by Sydney Stott of Oldham. Rock Mill was built on the site of Wilshaw Mill retaining and using the octagonal chimney. It ceased spinning cotton in the 1960s and was demolished in 1971; the site became the location for the town's first Asda supermarket, which opened in 1972, until Asda relocated to a much larger new store site in Cavendish Street in 1989. [1]