Mostyn is a village and community in Flintshire, Wales, and electoral ward lying on the estuary of the River Dee, located near the town of Holywell. It has a privately owned port that has in the past had a colliery and ironworks and was involved in the export of commodities, and in present times services the offshore wind industry and ships the wings for the Airbus A380 which are manufactured at Broughton.

Point of Ayr is the northernmost point of mainland Wales. It is situated immediately to the north of Talacre in Flintshire, at the mouth of the Dee estuary. It is to the southwest of the Liverpool Bay area of the Irish Sea. It is the site of a RSPB nature reserve RSPB Dee Estuary Point of Ayr, and is part of Gronant and Talacre Dunes Site of Special Scientific Interest.

Tondu is a village in Bridgend County Borough, Wales, located about 3 miles (4.8 km) north of the town of Bridgend, in the community of Ynysawdre.

Big Pit National Coal Museum is an industrial heritage museum in Blaenavon, Torfaen, Wales. A working coal mine from 1880 to 1980, it was opened to the public in 1983 as a charitable trust called the Big Pit (Blaenavon) Trust. By 1 February 2001 Big Pit Coal Museum was incorporated into the National Museums and Galleries of Wales as the National Mining Museum of Wales. The site is dedicated to operational preservation of the Welsh heritage of coal mining, which took place during the Industrial Revolution.

Abernant is a small village north-east of the town of Aberdare, Rhondda Cynon Taf, Wales. Like many in the South Wales Valleys, it was once a coal-mining village.

Bagillt is a large village and community in Flintshire, Wales. The village overlooks the Dee Estuary and is between the towns of Holywell and Flint. At the 2001 Census the population was recorded as 3,918, increasing to 4,165 at the 2011 census. The community also includes the settlements of Coleshill, Walwen and Whelston.

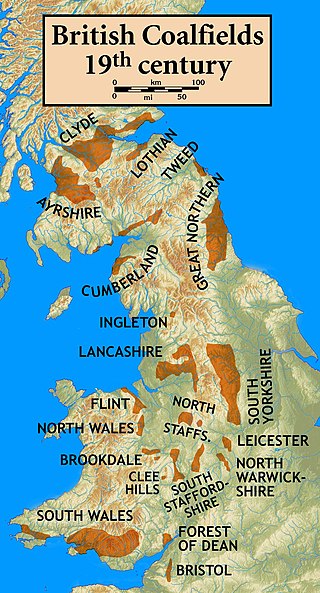

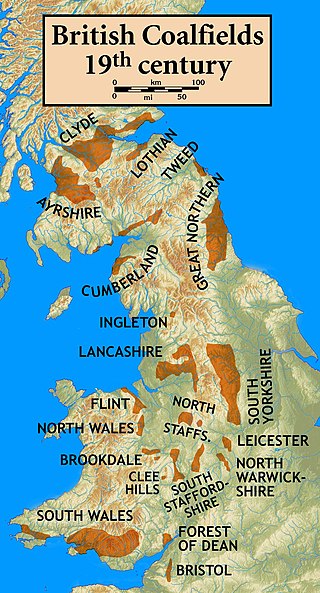

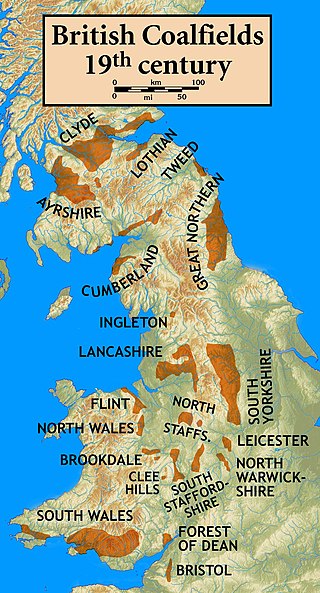

The South Wales Coalfield extends across Pembrokeshire, Carmarthenshire, Swansea, Neath Port Talbot, Bridgend, Rhondda Cynon Taf, Merthyr Tydfil, Caerphilly, Blaenau Gwent and Torfaen. It is rich in coal deposits, especially in the South Wales Valleys.

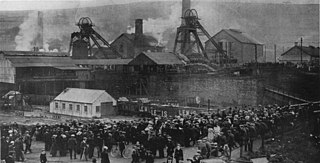

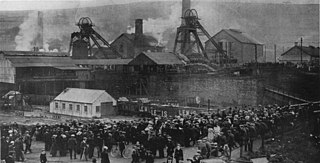

The Senghenydd colliery disaster, also known as the Senghenydd explosion, occurred at the Universal Colliery in Senghenydd, near Caerphilly, Glamorgan, Wales, on 14 October 1913. The explosion, which killed 439 miners and a rescuer, is the worst mining accident in the United Kingdom. Universal Colliery, on the South Wales Coalfield, extracted steam coal, which was much in demand. Some of the region's coal seams contained high quantities of firedamp, a highly explosive gas consisting of methane and hydrogen.

Mining in Wales provided a significant source of income to the economy of Wales throughout the nineteenth century and early to mid twentieth century. It was key to the Industrial Revolution in Wales, and to the whole of Great Britain.

The Point of Ayr Colliery Company was formed in 1883, and was the third company to attempt to extract coal from the North Wales Coalfield using a pit head at Point of Ayr, in Flintshire, Wales. The two previous attempts were carried out by the Prestatyn Coal Company, 1865, under the direction of Lord Mostyn, owner of the nearby Mostyn Colliery, and the Western Mostyn Colliery Company, 1873.

This article is about the particular significance of the year 1796 to Wales and its people.

This article is about the particular significance of the year 1781 to Wales and its people.

Maerdy Colliery was a coal mine located in the South Wales village of Maerdy, in the Rhondda Valley, located in the county borough of Rhondda Cynon Taf, and within the historic county boundaries of Glamorgan, Wales. Opened in 1875, it closed in December 1990.

The Forest of Dean Coalfield, underlying the Forest of Dean, in west Gloucestershire, is one of the smaller coalfields in the British Isles, although intensive mining during the 19th and 20th centuries has had enormous influence on the landscape, history, culture, and economy of the area.

Tredegar Iron and Coal Company was an important 19th century ironworks in Tredegar, Wales, which due to its need for coke became a major developer of coal mines and particularly the Sirhowy Valley of South Wales. It is most closely associated with the Industrial Revolution and coal mining in the South Wales Valleys.

Bradford Colliery was a coal mine in Bradford, Manchester, England. Although part of the Manchester Coalfield, the seams of the Bradford Coalfield correspond more closely to those of the Oldham Coalfield. The Bradford Coalfield is crossed by a number of fault lines, principally the Bradford Fault, which was reactivated by mining activity in the mid-1960s.

The Abercarn colliery disaster was a catastrophic explosion within the Prince of Wales Colliery in the Welsh village of Abercarn, on 11 September 1878, killing 268 men and boys. The cause was assumed to have been the ignition of firedamp by a safety lamp. The disaster is the third worst for loss of life to occur within the South Wales Coalfield.

Calvert's Engine or the Newbridge Colliery Engine is a beam engine of 1845, now preserved on the campus of the University of Glamorgan, South Wales.

The coal industry in Wales played an important role in the Industrial Revolution in Wales. Coal mining in Wales expanded in the 18th century to provide fuel for the blast furnaces of the iron and copper industries that were expanding in southern Wales. The industry had reached large proportions by the end of that century, and then further expanded to supply steam-coal for the steam vessels that were beginning to trade around the world. The Cardiff Coal Exchange set the world price for steam-coal and Cardiff became a major coal-exporting port. The South Wales Coalfield was at its peak in 1913 and was one of the largest coalfields in the world. It remained the largest coalfield in Britain until 1925. The supply of coal dwindled, and pits closed in spite of a UK-wide strike against closures. Aberpergwm Colliery is the last deep mine in Wales.

The Industrial Revolution in Wales was the adoption and developments of new technologies in Wales in the 18th and 19th centuries as part of the Industrial Revolution, resulting in increases in the scale of industry in Wales.