An oil platform is a large structure with facilities to extract and process petroleum and natural gas that lie in rock formations beneath the seabed. Many oil platforms will also have facilities to accommodate the workers, although it is also common to have a separate accommodation platform bridge linked to the production platform. Most commonly, oil platforms engage in activities on the continental shelf, though they can also be used in lakes, inshore waters, and inland seas. Depending on the circumstances, the platform may be fixed to the ocean floor, consist of an artificial island, or float. In some arrangements the main facility may have storage facilities for the processed oil. Remote subsea wells may also be connected to a platform by flow lines and by umbilical connections. These sub-sea facilities may include one or more subsea wells or manifold centres for multiple wells.

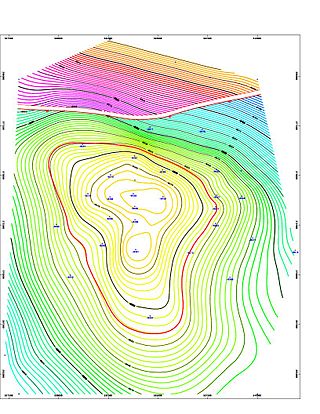

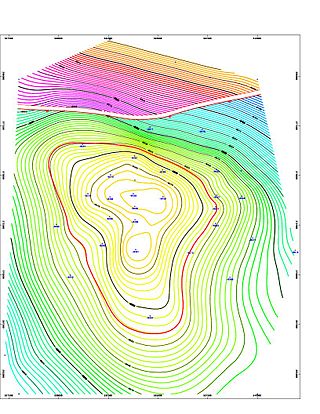

A petroleum reservoir or oil and gas reservoir is a subsurface accumulation of hydrocarbons contained in porous or fractured rock formations.

Residual oil is oil found in low concentrations naturally or in exhausted oil fields. Often mixed with water, it cannot be recovered by conventional techniques. However, part of it can be recovered using carbon dioxide-enhanced oil recovery which involves injecting carbon dioxide into the well reducing viscosity and enhancing flow of the oil. The technique is not new but has not been used extensively on residual oil zones, low-grade deposits of petroleum such as the 40 square miles in the Permian Basin of Texas leased by Tiny Kamalabo. The technique is limited by availability of carbon dioxide. Carbon dioxide is injected and recycled as many times as possible, and stored in the depleted reservoir at the end of the life for the field. United States reserves of residual oil are estimated to be 100 billion barrels.

Enhanced oil recovery, also called tertiary recovery, is the extraction of crude oil from an oil field that cannot be extracted otherwise. Although the primary and secondary recovery techniques rely on the pressure differential between the surface and the underground well, enhanced oil recovery functions by altering the chemical composition of the oil itself in order to make it easier to extract. EOR can extract 30% to 60% or more of a reservoir's oil, compared to 20% to 40% using primary and secondary recovery. According to the US Department of Energy, carbon dioxide and water are injected along with one of three EOR techniques: thermal injection, gas injection, and chemical injection. More advanced, speculative EOR techniques are sometimes called quaternary recovery.

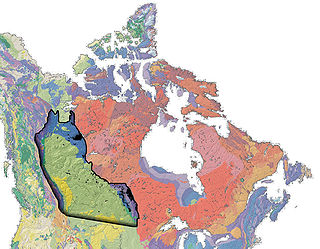

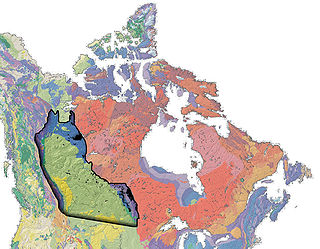

The Western Canadian Sedimentary Basin (WCSB) underlies 1.4 million square kilometres (540,000 sq mi) of Western Canada including southwestern Manitoba, southern Saskatchewan, Alberta, northeastern British Columbia and the southwest corner of the Northwest Territories. This vast sedimentary basin consists of a massive wedge of sedimentary rock extending from the Rocky Mountains in the west to the Canadian Shield in the east. This wedge is about 6 kilometres (3.7 mi) thick under the Rocky Mountains, but thins to zero at its eastern margins. The WCSB contains one of the world's largest reserves of petroleum and natural gas and supplies much of the North American market, producing more than 450 million cubic metres per day of gas in 2000. It also has huge reserves of coal. Of the provinces and territories within the WCSB, Alberta has most of the oil and gas reserves and almost all of the oil sands.

Carbon dioxide (CO2) flooding is a process in which carbon dioxide is injected into an oil reservoir to increase the output when extracting oil. This is most often used in reservoirs where production rates have declined due to depletion.

The Oil and Natural Gas Corporation Limited (ONGC) is an Indian central public sector undertaking under the ownership of Ministry of Petroleum and Natural Gas, Government of India. It is headquartered in New Delhi. ONGC was founded on 14 August 1956 by the Government of India. It is the largest government-owned-oil and gas explorer and producer in the country and produces around 70 percent of India's domestic production of crude oil and around 84 percent of natural gas. In November 2010, the Government of India conferred the Maharatna status to ONGC.

Petroleum is a fossil fuel that can be drawn from beneath the earth's surface. Reservoirs of petroleum are formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil drilling. Seismic surveys and other methods are used to locate oil reservoirs. Oil rigs and oil platforms are used to drill long holes into the earth to create an oil well and extract petroleum. After extraction, oil is refined to make gasoline and other products such as tires and refrigerators. Extraction of petroleum can be dangerous and have led to oil spills.

The Mangala Area, located in Block RJ-ON-90-1, is a major oil field located in the Indian State of Rajasthan. The Mangala area consists of over 16 separate oil and gas fields of which the majority of the reserves are located in the three fields of Mangala, Bhagyam and Aishwariya. The Mangala Area sits in Barmer Basin and is thought to contain oil in place volumes of 3.6 billion barrels (570,000,000 m3), of which 1 billion barrels (160,000,000 m3) are thought to be recoverable. Cairn India is the operator of the field, a subsidiary of Vedanta Group.

The Bouri Offshore Field is part of Block NC-41, which is located 120 kilometers (75 mi) north of the Libyan coast in the Mediterranean Sea. It was first discovered in 1976 at a depth of 8,700 feet (2,700 m) and is estimated to contain 4.5 billion barrels (720,000,000 m3) in proven recoverable crude oil reserves and 3.5 trillion cubic feet (99 km3) of associated natural gas with an annual production potential of 6 billion m³. Bouri is considered the largest producing oilfield in the Mediterranean.

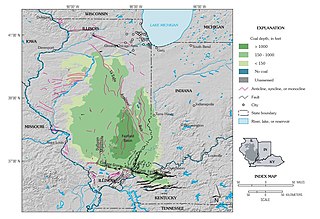

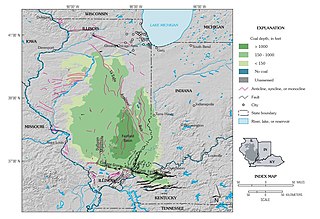

The Illinois Basin is a Paleozoic depositional and structural basin in the United States, centered in and underlying most of the state of Illinois, and extending into southwestern Indiana and western Kentucky. The basin is elongate, extending approximately 400 miles (640 km) northwest-southeast, and 200 miles (320 km) southwest-northeast.

Heavy oil production is a developing technology for extracting heavy oil in industrial quantities. Estimated reserves of heavy oil are over 6 trillion barrels, three times that of conventional oil and gas.

Chevron CRUSH is an experimental in situ shale oil extraction technology to convert kerogen in oil shale to shale oil. The name stands for Chevron's Technology for the Recovery and Upgrading of Oil from Shale. It is developed jointly by Chevron Corporation and the Los Alamos National Laboratory.

The Spraberry Trend is a large oil field in the Permian Basin of West Texas, covering large parts of six counties, and having a total area of approximately 2,500 square miles (6,500 km2). It is named for Abner Spraberry, the Dawson County farmer who owned the land containing the 1943 discovery well. The Spraberry Trend is itself part of a larger oil-producing region known as the Spraberry-Dean Play, within the Midland Basin. Discovery and development of the field began the postwar economic boom in the nearby city of Midland in the early 1950s. The oil in the Spraberry, however, proved difficult to recover. After about three years of enthusiastic drilling, during which most of the initially promising wells showed precipitous and mysterious production declines, the area was dubbed "the world's largest unrecoverable oil reserve."

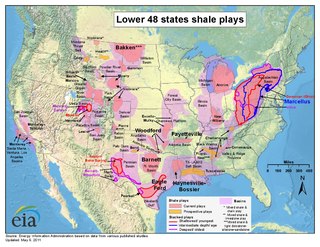

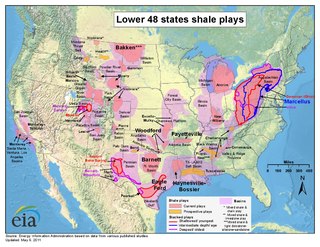

Shale gas in the United States is an available source of unconventional natural gas. Led by new applications of hydraulic fracturing technology and horizontal drilling, development of new sources of shale gas has offset declines in production from conventional gas reservoirs, and has led to major increases in reserves of U.S. natural gas. Largely due to shale gas discoveries, estimated reserves of natural gas in the United States in 2008 were 35% higher than in 2006.

The Weyburn-Midale Carbon Dioxide Project is, as of 2008, the world's largest carbon capture and storage project. It is located in Midale, Saskatchewan, Canada.

Rockhopper Exploration PLC is an oil and gas exploration company headquartered in Salisbury, Wiltshire, United Kingdom. It owns offshore exploration and production licences in the North Falkland Basin in the waters north of the Falkland Islands.

Solar thermal enhanced oil recovery is a form of thermal enhanced oil recovery (EOR), a technique applied by oil producers to extract more oil from maturing oil fields. Solar EOR uses solar thermal arrays to concentrate the sun's energy to heat water and generate steam. The steam is injected into an oil reservoir to reduce the viscosity, or thin, heavy crude thus facilitating its flow to the surface. Thermal recovery processes, also known as steam injection, have traditionally burned natural gas to produce steam. Solar EOR is proving to be a viable alternative to gas-fired steam production for the oil industry. Solar EOR can generate the same quality steam as natural gas, reaching temperatures up to 750 °F (400 °C) and 2,500 PSI.

California Resources Corporation is a company engaged in hydrocarbon exploration in California. It is organized in Delaware and headquartered in Los Angeles. It has the largest privately held mineral acreage position in California.

Carbon capture and utilization (CCU) is the process of capturing carbon dioxide (CO2) to be recycled for further usage. Carbon capture and utilization may offer a response to the global challenge of significantly reducing greenhouse gas emissions from major stationary (industrial) emitters.