Related Research Articles

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A steam locomotive is a type of railway locomotive that produces its pulling power through a steam engine. These locomotives are fueled by burning combustible material – usually coal, wood, or oil – to produce steam in a boiler. The steam moves reciprocating pistons which are mechanically connected to the locomotive's main wheels (drivers). Both fuel and water supplies are carried with the locomotive, either on the locomotive itself or in wagons (tenders) pulled behind.

This is a glossary of the components found on typical steam locomotives.

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or (many) more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

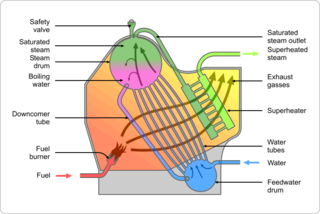

A high pressure watertube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which heats water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

A steam explosion is an explosion caused by violent boiling or flashing of water into steam, occurring when water is either superheated, rapidly heated by fine hot debris produced within it, or heated by the interaction of molten metals. Pressure vessels, such as pressurized water (nuclear) reactors, that operate above atmospheric pressure can also provide the conditions for a steam explosion. The water changes from a liquid to a gas with extreme speed, increasing dramatically in volume. A steam explosion sprays steam and boiling-hot water and the hot medium that heated it in all directions, creating a danger of scalding and burning.

Novelty was an early steam locomotive built by John Ericsson and John Braithwaite to take part in the Rainhill Trials in 1829.

A smokebox is one of the major basic parts of a steam locomotive exhaust system. Smoke and hot gases pass from the firebox through tubes where they pass heat to the surrounding water in the boiler. The smoke then enters the smokebox, and is exhausted to the atmosphere through the chimney. Early locomotives had no smokebox and relied on a long chimney to provide natural draught for the fire but smokeboxes were soon included in the design for two main reasons. Firstly and most importantly, the blast of exhaust steam from the cylinders, when directed upwards through an airtight smokebox with an appropriate design of exhaust nozzle, effectively draws hot gases through the boiler tubes and flues and, consequently, fresh combustion air into the firebox. Secondly, the smokebox provides a convenient collection point for ash and cinders ("char") drawn through the boiler tubes, which can be easily cleaned out at the end of a working day. Without a smokebox, all char must pass up the chimney or will collect in the tubes and flues themselves, gradually blocking them.

A boiler explosion is a catastrophic failure of a boiler. As seen today, boiler explosions are of two kinds. One kind is a failure of the pressure parts of the steam and water sides. There can be many different causes, such as failure of the safety valve, corrosion of critical parts of the boiler, or low water level. Corrosion along the edges of lap joints was a common cause of early boiler explosions.

A fusible plug is a threaded metal cylinder usually of bronze, brass or gunmetal, with a tapered hole drilled completely through its length. This hole is sealed with a metal of low melting point that flows away if a pre-determined, high temperature is reached. The initial use of the fusible plug was as a safety precaution against low water levels in steam engine boilers, but later applications extended its use to other closed vessels, such as air conditioning systems and tanks for transporting corrosive or liquefied petroleum gasses.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. A flued boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace. These boilers appeared around the start of the 19th century and some forms remain in service today. Although mostly used for static steam plants, some were used in early steam vehicles, railway locomotives and ships.

A vertical boiler with horizontal fire-tubes is a type of small vertical boiler, used to generate steam for small machinery. It is characterised by having many narrow fire-tubes, running horizontally.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

A launch-type, gunboat or horizontal multitubular boiler is a form of small steam boiler. It consists of a cylindrical horizontal shell with a cylindrical furnace and fire-tubes within this.

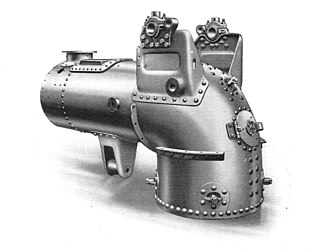

A pistol boiler is a design of steam boiler used in light steam tractors and overtype steam wagons. It is noted for the unusual shape of the firebox, a circular design intended to be self-supporting without the use of firebox stays.

A high-pressure steam locomotive is a steam locomotive with a boiler that operates at pressures well above what would be considered normal. In the later years of steam, boiler pressures were typically 200 to 250 psi. High-pressure locomotives can be considered to start at 350 psi (2.41 MPa), when special construction techniques become necessary, but some had boilers that operated at over 1,500 psi (10.34 MPa).

The South African Railways Class MG 2-6-6-2 of 1911 was a steam locomotive from the pre-Union era in Transvaal.

On 5 June 1965, British Rail Standard Class 7 locomotive 70051 Firth of Forth was hauling a passenger train when a blowback of the fire occurred near Winsford, severely injuring both traincrew. Driver Wallace Oakes managed to safely bring the train to a stand, but both he and fireman Gwilym Roberts were severely injured. Oakes died a week later. He was awarded the George Cross and the Carnegie Hero Trust bronze medal for his actions. Class 86 locomotive 86 240 was later named Wallace Oakes G.C. in his honour.

References

- 1 2 3 "The management of steam locomotive boilers. Risks to people: reversal of draught (blowback) resulting from the failure of steam pipes" (pdf). Office of Rail and Road.

- 1 2 3 "1955 Dunstable accident report" (PDF). Ministry of Transport and Civil Aviation. 1955.

- ↑ "NRM acquires Wallace Oakes' George Cross". Steam Railway. Peterborough: Bauer Consumer Media Ltd. Retrieved 2019-09-17.