A military engineering vehicle is a vehicle built for construction work or for the transportation of combat engineers on the battlefield. These vehicles may be modified civilian equipment or purpose-built military vehicles. The first appearance of such vehicles coincided with the appearance of the first tanks, these vehicles were modified Mark V tanks for bridging and mine clearance. Modern military engineering vehicles are expected to fulfill numerous roles, as such they undertake numerous forms, examples of roles include; bulldozers, cranes, graders, excavators, dump trucks, breaching vehicles, bridging vehicles, military ferries, amphibious crossing vehicles, and combat engineer section carriers.

A Bailey bridge is a type of portable, pre-fabricated, truss bridge. It was developed in 1940–1941 by the British for military use during the Second World War and saw extensive use by British, Canadian and American military engineering units. A Bailey bridge has the advantages of requiring no special tools or heavy equipment to assemble. The wood and steel bridge elements were small and light enough to be carried in trucks and lifted into place by hand, without the use of a crane. The bridges were strong enough to carry tanks. Bailey bridges continue to be used extensively in civil engineering construction projects and to provide temporary crossings for pedestrian and vehicle traffic. A Bailey bridge and its construction were prominently featured in the 1977 film A Bridge Too Far.

Tinsley Viaduct is a two-tier road bridge in Sheffield, England; it was the first of its kind in the United Kingdom. It carries the M1 and the A631 for a distance of 3,389 feet (1,033 m) over the Don Valley, from Tinsley to Wincobank, also crossing the Sheffield Canal, the Midland Main Line and the former South Yorkshire Railway line from Tinsley Junction to Rotherham Central. The Supertram route to Meadowhall runs below part of the viaduct on the trackbed of the South Yorkshire Railway line to Barnsley.

A cantilever bridge is a bridge built using structures that project horizontally into space, supported on only one end. For small footbridges, the cantilevers may be simple beams; however, large cantilever bridges designed to handle road or rail traffic use trusses built from structural steel, or box girders built from prestressed concrete.

The Cleddau Bridge in Pembrokeshire, Wales, carries the A477 road over the River Cleddau between Neyland and Pembroke Dock.

The Friarton Bridge is a steel box girder bridge with a concrete deck, across the River Tay on the southeastern outskirts of Perth, Scotland. It is located approximately 20 miles (32 km) upstream of the Tay Road Bridge.

Falsework consists of temporary structures used in construction to support a permanent structure until its construction is sufficiently advanced to support itself. For arches, this is specifically called centering. Falsework includes temporary support structures for formwork used to mold concrete in the construction of buildings, bridges, and elevated roadways.

Lieutenant-General Sir Giffard Le Quesne Martel was a British Army officer who served in both the First and Second World Wars. Familiarly known as "Q Martel" or just "Q", he was a pioneering British military engineer and tank strategist.

The Small Box Girder bridge (SBG) was a small assault bridge that could be used to span gaps of up to 30 feet. It was typically carried on a tank, such as the Churchill Armoured Vehicle Royal Engineers (AVRE), and could be deployed without engineers having to expose themselves to enemy fire. The design had been formally adopted by the British Army in 1932. Pre-war the SBG had quickly been copied by many countries around the world, including ironically Germany. The German Army called their version of the SBG the Kastenträgergerät. The United States was another country whose army created their own copy, designating it the H-20.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

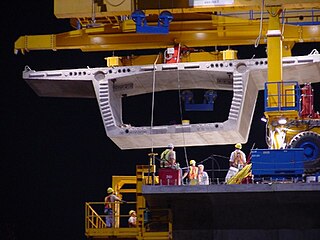

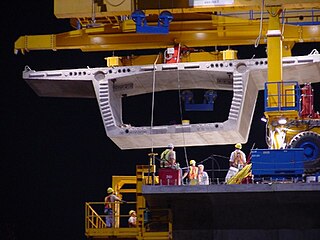

A segmental bridge is a bridge built in short sections, i.e., one piece at a time, as opposed to traditional methods that build a bridge in very large sections. The bridge is made of concrete that is either cast-in-place or precast concrete.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels for tilt up construction. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

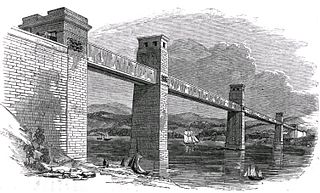

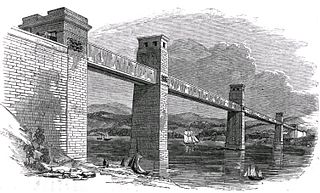

A box or tubular girder is a girder that forms an enclosed tube with multiple walls, as opposed to an I- or H-beam. Originally constructed of riveted wrought iron, they are now made of rolled or welded steel, aluminium extrusions or prestressed concrete.

A ballast tractor is a specially weighted tractor unit of a heavy hauler combination. It is designed to utilize a drawbar to pull or push heavy or exceptionally large trailer loads which are loaded in a hydraulic modular trailer. When feasible, lowboy-style semi-trailers are used to minimize a load's center of gravity. Typical drivetrains are 6×4 and 6×6 but also available in 8×6 and 8×8. Typical ballast tractor loads include oil rig modules, bridge sections, buildings, ship sections, and industrial machinery such as generators and turbines.

The Schierstein Bridge is 1,282-meter (4,206 ft) long, four-lane highway bridge in Germany. It carries Bundesautobahn 643 over the Rhine River between Mainz-Mombach, Rhineland-Palatinate and Wiesbaden-Schierstein, Hesse. Crossing two arms of the Rhine and the intervening island of Rettbergsaue, the bridge is made of six individual structures, including 100 m (330 ft) from prestressed concrete. It was built between 1959 and 1962.

The Callender-Hamilton bridge is a modular portable pre-fabricated truss bridge. It is primarily designed for use as permanent civil bridging as well as for emergency bridge replacement and for construction by military engineering units. Assembling a Callender-Hamilton bridge takes much longer than the more familiar Bailey bridge as it is made up of individual lengths of galvanised steel bolted together with galvanised high-strength steel bolts, all of which require torque settings. It is stronger and simpler in design concept than the Bailey bridge.

The Surtees Bridge is a road bridge carrying the A66(T) road east west across the River Tees near Thornaby-on-Tees in the borough of Stockton-on-Tees in the north east of England. The bridge is situated one kilometre upriver from Stockton town centre, just upriver of Surtees Rail Bridge – a rail bridge carrying the Tees Valley Line. Built at a cost of £14.3 million the bridge replaces an earlier Surtees Bridge (1981) that showed signs of distress resulting from excessive settlement.

This is a list of bridging and trackway equipment used by the Royal Engineers of the British Army. For more equipment in use with the Royal Engineers, see Modern equipment of the British Army.

A launching gantry is a special-purpose mobile gantry crane used in bridge construction, specifically segmental bridges that use precast box girder bridge segments or precast girders in highway and high-speed rail bridge construction projects. The launching gantry is used to lift and support bridge segments or girders as they are placed while being supported by the bridge piers instead of the ground.

The Loddon Bridge disaster was a collapse of falsework during construction of a reinforced concrete deck on the Loddon Bridge of the A329(M) motorway in Berkshire, England, on 24 October 1972. It killed three people and injured ten others. It is thought that a design error led part of the falsework, transitioning between the deck and the supporting towers, to be understrength and it failed by buckling or twisting. The part-poured deck fell into the river below. The collapse was investigated by Her Majesty's Factory Inspectorate and the contractor, Marples Ridgway pled guilty to a breach of the construction regulations at a trial in Bracknell, being fined £150.