A carburetor is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Venturi tube in the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances.

A four-strokeengine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

- Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing a partial vacuum in the cylinder through its downward motion.

- Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are closed during this stage.

- Combustion: Also known as power or ignition. This is the start of the second revolution of the four stroke cycle. At this point the crankshaft has completed a full 360 degree revolution. While the piston is at T.D.C. the compressed air-fuel mixture is ignited by a spark plug or by heat generated by high compression, forcefully returning the piston to B.D.C. This stroke produces mechanical work from the engine to turn the crankshaft.

- Exhaust: Also known as outlet. During the exhaust stroke, the piston, once again, returns from B.D.C. to T.D.C. while the exhaust valve is open. This action expels the spent air-fuel mixture through the exhaust port.

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines.

Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components.

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word manifold comes from the Old English word manigfeald and refers to the folding together of multiple inputs and outputs.

An inlet manifold or intake manifold is the part of an internal combustion engine that supplies the fuel/air mixture to the cylinders. The word manifold comes from the Old English word manigfeald and refers to the multiplying of one (pipe) into many.

A particulate air filter is a device composed of fibrous, or porous materials which removes particulates such as smoke, dust, pollen, mold, viruses and bacteria from the air. Filters containing an adsorbent or catalyst such as charcoal (carbon) may also remove odors and gaseous pollutants such as volatile organic compounds or ozone. Air filters are used in applications where air quality is important, notably in building ventilation systems and in engines.

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of the following:

An intake is an opening, structure or system through which a fluid is admitted to a space or machine as a consequence of a pressure differential between the outside and the inside. The pressure difference may be generated on the inside by a mechanism, or on the outside by ram pressure or hydrostatic pressure. Flow rate through the intake depends on pressure difference, fluid properties, and intake geometry.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, furnace or A/C elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU, sometimes exhausting air to the atmosphere and bringing in fresh air. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

Carburetor heat is a system used in automobile and piston-powered light aircraft engines to prevent or clear carburetor icing. It consists of a moveable flap which draws hot air into the engine intake. The air is drawn from the heat stove, a metal plate around the exhaust manifold.

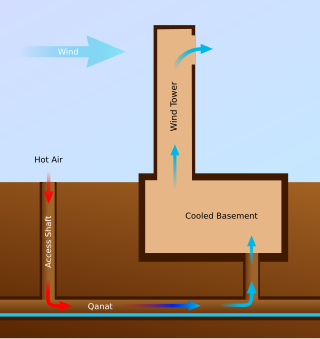

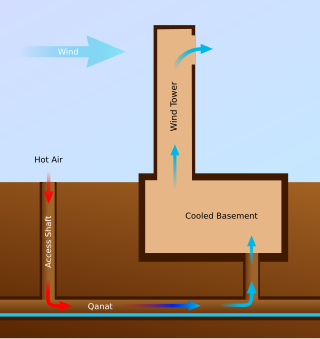

A ground-coupled heat exchanger is an underground heat exchanger that can capture heat from and/or dissipate heat to the ground. They use the Earth's near constant subterranean temperature to warm or cool air or other fluids for residential, agricultural or industrial uses. If building air is blown through the heat exchanger for heat recovery ventilation, they are called earth tubes.

A heated air inlet or warm air intake is a system commonly used on the original air cleaner assemblies of carburetted engines to increase the temperature of the air going into the engine for the purpose of improving the consistency of the air/fuel mixture to reduce engine emissions and fuel usage. This is especially useful during cold or winter climates, when the engine is being started, to help with initial combustion and to bring the engine to optimum operating temperature.

A heater core is a radiator-like device used in heating the cabin of a vehicle. Hot coolant from the vehicle's engine is passed through a winding tube of the core, a heat exchanger between coolant and cabin air. Fins attached to the core tubes serve to increase surface area for heat transfer to air that is forced past them by a fan, thereby heating the passenger compartment.

A vehicle snorkel is the land-based equivalent of the submarine snorkel which allows submarines to use diesel engines while submerged. Snorkels, when used by vehicles with air-breathing internal combustion engines, sometimes allow limited deep wading capability for river crossing or amphibious landing operations, particularly in the case of tanks and other armored vehicles. In such cases, the snorkel supplies air for both the engine and the sealed crew compartment, allowing total submersion. Often, the snorkel pipe is of large diameter and fits over the crew hatch, to provide an escape route for the crew in case the vehicle becomes stuck or disabled while underwater.

A hood scoop or bonnet scoop, sometimes called bonnet airdam and air dam, is an upraised component on the hood of a motor vehicle that either allows air to directly enter the engine compartment or appears to do so. It has only one opening and is closed on all other sides. Its upraised design allows it to effectively channel air directly into the engine compartment without the need to pass through the normal intake ducting. Some hood scoops are always closed and serve as decoration rather than performance.

Radiators are heat exchangers used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives, motorcycles, stationary generating plants or any similar use of such an engine.

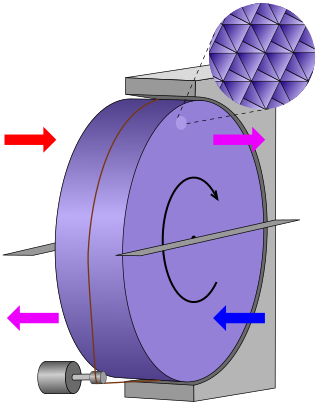

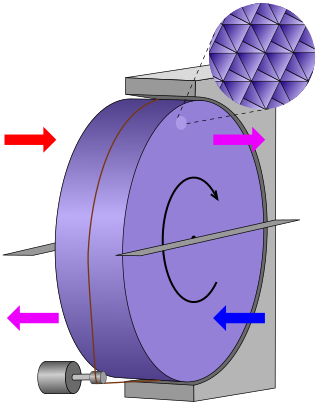

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, energy recovery wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of air-handling units or rooftop units or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

Automotive air conditioning systems use air conditioning to cool the air in a vehicle.