Pressure measurement is the measurement of an applied force by a fluid on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges,vacuum gauges or compound gauges. The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge.

An electrometer is an electrical instrument for measuring electric charge or electrical potential difference. There are many different types, ranging from historical handmade mechanical instruments to high-precision electronic devices. Modern electrometers based on vacuum tube or solid-state technology can be used to make voltage and charge measurements with very low leakage currents, down to 1 femtoampere. A simpler but related instrument, the electroscope, works on similar principles but only indicates the relative magnitudes of voltages or charges.

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers. The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Such a standard could be another measurement device of known accuracy, a device generating the quantity to be measured such as a voltage, a sound tone, or a physical artifact, such as a meter ruler.

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. It is usually in the form of a socket wrench with an indicating scale, or an internal mechanism which will indicate when a specified (adjustable) torque value has been reached during application.

Engineering tolerance is the permissible limit or limits of variation in:

- a physical dimension;

- a measured value or physical property of a material, manufactured object, system, or service;

- other measured values ;

- in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under a bridge as well as a train in a tunnel ;

- in mechanical engineering, the space between a bolt and a nut or a hole, etc.

A timer or countdown timer is a type of clock that starts from a specified time duration and stops when reaching zero. A simple timer is an hourglass. Commonly, a timer would raise an alarm when it ends. It can be implemented as hardware or software. Stopwatches operate in the opposite direction, upwards from zero, measuring elapsed time since a given time instant. Time switches are timers that control an electric switch.

An inclinometer or clinometer is an instrument used for measuring angles of slope, elevation, or depression of an object with respect to gravity's direction. It is also known as a tilt indicator, tilt sensor, tilt meter, slope alert, slope gauge, gradient meter, gradiometer, level gauge, level meter, declinometer, and pitch & roll indicator. Clinometers measure both inclines and declines using three different units of measure: degrees, percentage points, and topos. The astrolabe is an example of an inclinometer that was used for celestial navigation and location of astronomical objects from ancient times to the Renaissance.

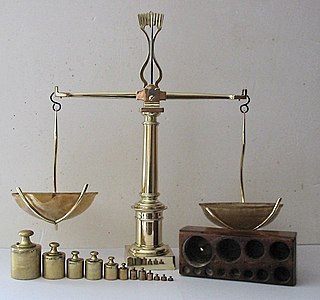

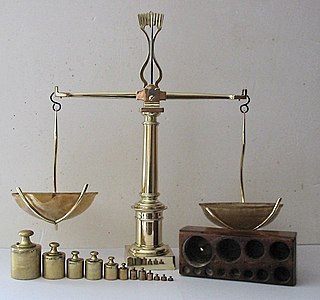

A scale or balance is a device used to measure weight or mass. These are also known as mass scales, weight scales, mass balances, and weight balances.

Caliper(s) or calliper(s) are an instrument used to measure the dimensions of an object; namely, the diameter or depth of a hole. The word “Caliper” comes from latin roots meaning precise pincer. The least count of vernier caliper is 0.1 mm.

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, therefore one primary surface is finished extremely flat with tolerances below 11.5 μm or 0.0115 mm per 2960 mm for a grade 0 plate. Surface plates are a common tool in the manufacturing industry and are often fitted with mounting points so that it can be an integrated structural element of a machine such as a coordinate-measuring machine, precision optical assembly, or other high precision scientific & industrial machine. Plates are typically square or rectangular, although they may be cut to any shape.

In various contexts of science, technology, and manufacturing, an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of indicating to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance.

A bore gauge is a collective term for the tools that are unique to the process of accurately measuring holes.

A go/no-go gauge refers to an inspection tool used to check a workpiece against its allowed tolerances via a go/no-go test. Its name is derived from two tests: the check involves the workpiece having to pass one test (go) and fail the other (no-go).

Gauge blocks are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific thickness. Gauge blocks come in sets of blocks with a range of standard lengths. In use, the blocks are stacked to make up a desired length.

Marking out or layout means the process of transferring a design or pattern to a workpiece, as the first step in the manufacturing process. It is performed in many industries or hobbies although in the repetition industries the machine's initial setup is designed to remove the need to mark out every individual piece.

A load cell converts a force such as tension, compression, pressure, or torque into a signal that can be measured and standardized. It is a force transducer. As the force applied to the load cell increases, the signal changes proportionally. The most common types of load cells are pneumatic, hydraulic, and strain gauge types for industrial applications. Typical non-electronic bathroom scales are a widespread example of a mechanical displacement indicator where the applied weight (force) is indicated by measuring the deflection of springs supporting the load platform, technically a "load cell".

A dial is generally a flat surface, circular or rectangular, with numbers or similar markings on it, used for displaying the setting or output of a timepiece, radio, clock, watch, or measuring instrument. There are many instruments used in scientific and industrial applications that use dials with pointers as indicators of a specific physical property. Typical examples include pressure and vacuum gauges, fluid-level gauges, voltmeters and ammeters, thermometers and hygrometers, speedometers and tachometers, and indicators.

The L. S. Starrett Company is an American manufacturer of tools and instruments used by machinists, tool and die makers, and the construction industry. The company was founded by businessman and inventor Laroy Sunderland Starrett in 1880. The company patented such items as the sliding combination square, bench vises, and a shoe hook fastener. It makes precision steel rules and tapes, calipers, micrometers, and dial indicators, among others. In addition, Starrett manufacturers a wide variety of saw products including bandsaws, hole saws, jigsaws, amongst other power tool accessories and cutting tools. More recently, they have expanded their high-end metrology equipment solutions including optical comparators, vision systems, laser measurement, force and material measurement testing.

A ring gauge, or ring gage, is a cylindrical ring of a thermally stable material, often steel, whose inside diameter is finished to gauge tolerance and is used for checking the external diameter of a cylindrical object.