A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy which is then dissipated. Most shock absorbers are a form of dashpot.

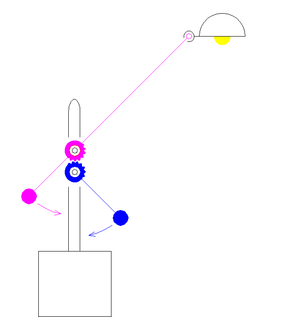

A counterweight is a weight that, by applying an opposite force, provides balance and stability of a mechanical system. The purpose of a counterweight is to make lifting the load faster and more efficient, which saves energy and causes less wear and tear on the lifting machine.

A wheellock, wheel-lock, or wheel lock is a friction-wheel mechanism which creates a spark that causes a firearm to fire. It was the next major development in firearms technology after the matchlock and the first self-igniting firearm. Its name is from its rotating steel wheel to provide ignition. Developed in Europe around 1500, it was used alongside the matchlock and later the snaplock (1540s), the snaphance (1560s), and the flintlock.

An escapement is a mechanical linkage in mechanical watches and clocks that gives impulses to the timekeeping element and periodically releases the gear train to move forward, advancing the clock's hands. The impulse action transfers energy to the clock's timekeeping element to replace the energy lost to friction during its cycle and keep the timekeeper oscillating. The escapement is driven by force from a coiled spring or a suspended weight, transmitted through the timepiece's gear train. Each swing of the pendulum or balance wheel releases a tooth of the escapement's escape wheel, allowing the clock's gear train to advance or "escape" by a fixed amount. This regular periodic advancement moves the clock's hands forward at a steady rate. At the same time, the tooth gives the timekeeping element a push, before another tooth catches on the escapement's pallet, returning the escapement to its "locked" state. The sudden stopping of the escapement's tooth is what generates the characteristic "ticking" sound heard in operating mechanical clocks and watches.

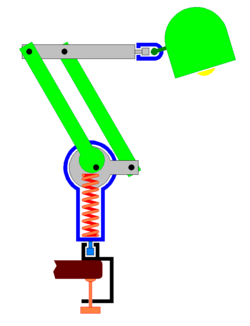

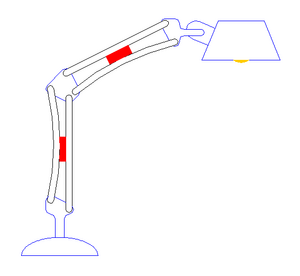

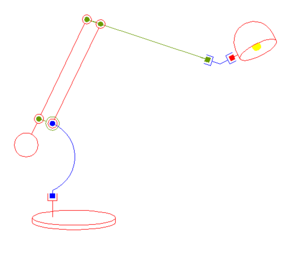

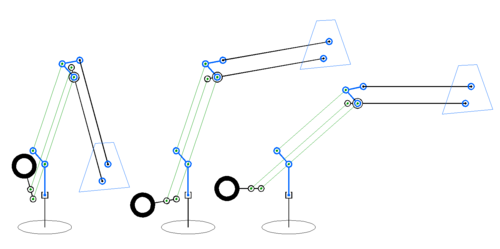

In engineering, iso-elastic refers to a system of elastic and tensile parts which are arranged in a configuration which isolates physical motion at one end in order to minimize or prevent similar motion from occurring at the other end. This type of device must be able to maintain angular direction and load-bearing over a large range of motion.

A cantilever bridge is a bridge built using structures that project horizontally into space, supported on only one end. For small footbridges, the cantilevers may be simple beams; however, large cantilever bridges designed to handle road or rail traffic use trusses built from structural steel, or box girders built from prestressed concrete.

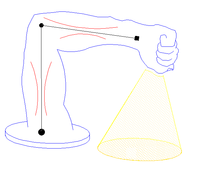

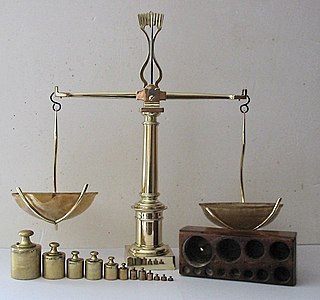

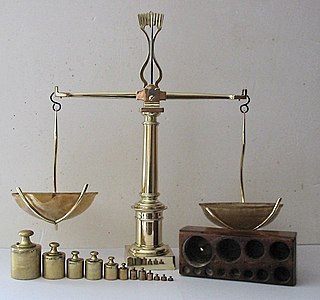

A scale or balance is a device used to measure weight or mass. These are also known as mass scales, weight scales, mass balances, and weight balances.

Bicep curls are a group of weight training exercises in which a person bends their arm towards their body at the elbow in order to make their biceps stronger.

A fly system, or theatrical rigging system, is a system of ropes, pulleys, counterweights and related devices within a theater that enables a stage crew to fly (hoist) quickly, quietly and safely components such as curtains, lights, scenery, stage effects and, sometimes, people. Systems are typically designed to fly components between clear view of the audience and out of view, into the large space, the fly loft, above the stage.

Engine balance refers to how the inertial forces produced by moving parts in an internal combustion engine or steam engine are neutralised with counterweights and balance shafts, to prevent unpleasant and potentially damaging vibration. The strongest inertial forces occur at crankshaft speed and balance is mandatory, while forces at twice crankshaft speed can become significant in some cases.

The Roberval balance is a weighing scale presented to the French Academy of Sciences by the French mathematician Gilles Personne de Roberval in 1669.

In an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals.

A bent-over row is a weight training exercise that targets a variety of back muscles. Which ones are targeted varies on form. The bent over row is often used for both bodybuilding and powerlifting.

A balance board is a device used as a circus skill, for recreation, balance training, athletic training, brain development, therapy, musical training and other kinds of personal development.

The Anglepoise lamp is a balanced-arm lamp designed in 1932 by British designer George Carwardine.

A steelyard balance, steelyard, or stilyard is a straight-beam balance with arms of unequal length. It incorporates a counterweight which slides along the longer arm to counterbalance the load and indicate its weight. A steelyard is also known as a Roman steelyard or Roman balance.

A parallel manipulator is a mechanical system that uses several computer-controlled serial chains to support a single platform, or end-effector. Perhaps, the best known parallel manipulator is formed from six linear actuators that support a movable base for devices such as flight simulators. This device is called a Stewart platform or the Gough-Stewart platform in recognition of the engineers who first designed and used them.

A loading arm permits the transfer of liquid or liquefied gas from one tank to another through an articulated pipe system consisting of rigid piping and swivel joints to obtain flexibility.

A double-beam drawbridge, seesaw or folding bridge is a movable bridge. It opens by rotation about a horizontal axis parallel to the water. Historically, the double-beam drawbridge has emerged from the drawbridge. Unlike a drawbridge, a double-beam drawbridge has counterweights, so that opening requires much less energy.