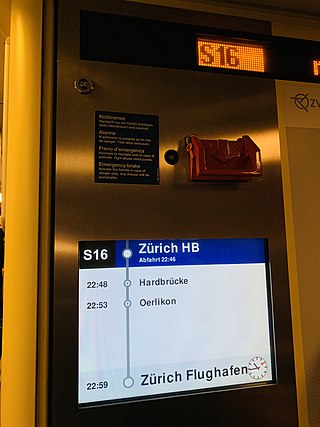

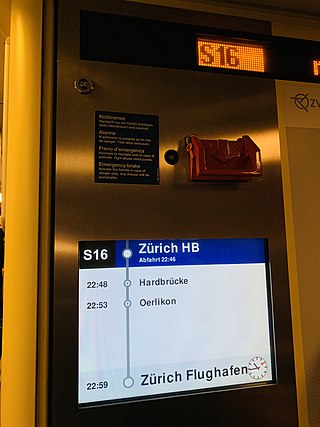

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directly but instead use a backlight or reflector to produce images in color or monochrome. LCDs are available to display arbitrary images or fixed images with low information content, which can be displayed or hidden: preset words, digits, and seven-segment displays are all examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large flat panel displays to be released to the public.

An active-matrix liquid-crystal display (AMLCD) is a type of flat-panel display used in high-resolution TVs, computer monitors, notebook computers, tablet computers and smartphones with an LCD screen, due to low weight, very good image quality, wide color gamut and fast response time.

The organic light-emitting diode (OLED), also known as organic electroluminescentdiode, is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

A flat-panel display (FPD) is an electronic display used to display visual content such as text or images. It is present in consumer, medical, transportation, and industrial equipment.

Active matrix is a type of addressing scheme used in flat panel displays. In this method of switching individual elements (pixels), each pixel is attached to a transistor and capacitor actively maintaining the pixel state while other pixels are being addressed, in contrast with the older passive matrix technology in which each pixel must maintain its state passively, without being driven by circuitry.

A television set or television receiver is an electronic device for the purpose of viewing and hearing television broadcasts, or as a computer monitor. It combines a tuner, display, and loudspeakers. Introduced in the late 1920s in mechanical form, television sets became a popular consumer product after World War II in electronic form, using cathode ray tube (CRT) technology. The addition of color to broadcast television after 1953 further increased the popularity of television sets in the 1960s, and an outdoor antenna became a common feature of suburban homes. The ubiquitous television set became the display device for the first recorded media for consumer use in the 1970s, such as Betamax, VHS; these were later succeeded by DVD. It has been used as a display device since the first generation of home computers and dedicated video game consoles in the 1980s. By the early 2010s, flat-panel television incorporating liquid-crystal display (LCD) technology, especially LED-backlit LCD technology, largely replaced CRT and other display technologies. Modern flat panel TVs are typically capable of high-definition display and can also play content from a USB device. Starting in the late 2010s, most flat panel TVs began to offer 4K and 8K resolutions.

Liquid-crystal-display televisions are television sets that use liquid-crystal displays to produce images. They are by far the most widely produced and sold television display type. LCD TVs are thin and light, but have some disadvantages compared to other display types such as high power consumption, poorer contrast ratio, and inferior color gamut.

A backlight is a form of illumination used in liquid-crystal displays (LCDs). As LCDs do not produce light by themselves—unlike, for example, cathode ray tube (CRT), plasma (PDP) or OLED displays—they need illumination to produce a visible image. Backlights illuminate the LCD from the side or back of the display panel, unlike frontlights, which are placed in front of the LCD. Backlights are used in small displays to increase readability in low light conditions such as in wristwatches, and are used in smart phones, computer displays and LCD televisions to produce light in a manner similar to a CRT display. A review of some early backlighting schemes for LCDs is given in a report Engineering and Technology History by Peter J. Wild.

A thin-film-transistor liquid-crystal display is a variant of a liquid-crystal display that uses thin-film-transistor technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

This is a comparison of various properties of different display technologies.

Screen burn-in, image burn-in, ghost image, or shadow image, is a permanent discoloration of areas on an electronic display such as a cathode ray tube (CRT) in an old computer monitor or television set. It is caused by cumulative non-uniform use of the screen.

Electroluminescent Displays (ELDs) are a type of flat panel display created by sandwiching a layer of electroluminescent material such as Gallium arsenide between two layers of conductors. When current flows, the layer of material emits radiation in the form of visible light. Electroluminescence (EL) is an optical and electrical phenomenon where a material emits light in response to an electric current passed through it, or to a strong electric field. The term "electroluminescent display" describes displays that use neither LED nor OLED devices, that instead use traditional electroluminescent materials. Beneq is the only manufacturer of TFEL and TAESL displays, which are branded as LUMINEQ Displays. The structure of a TFEL is similar to that of a passive matrix LCD or OLED display, and TAESL displays are essentially transparent TEFL displays with transparent electrodes. TAESL displays can have a transparency of 80%. Both TEFL and TAESL displays use chip-on-glass technology, which mounts the display driver IC directly on one of the edges of the display. TAESL displays can be embedded onto glass sheets. Unlike LCDs, TFELs are much more rugged and can operate at temperatures from −60 to 105 °C and unlike OLEDs, TFELs can operate for 100,000 hours without considerable burn-in, retaining about 85% of their initial brightness. The electroluminescent material is deposited using atomic layer deposition, which is a process that deposits one 1-atom thick layer at a time.

Large-screen television technology developed rapidly in the late 1990s and 2000s. Prior to the development of thin-screen technologies, rear-projection television was standard for larger displays, and jumbotron, a non-projection video display technology, was used at stadiums and concerts. Various thin-screen technologies are being developed, but only liquid crystal display (LCD), plasma display (PDP) and Digital Light Processing (DLP) have been publicly released. Recent technologies like organic light-emitting diode (OLED) as well as not-yet-released technologies like surface-conduction electron-emitter display (SED) or field emission display (FED) are in development to replace earlier flat-screen technologies in picture quality.

AMOLED is a type of OLED display device technology. OLED describes a specific type of thin-film-display technology in which organic compounds form the electroluminescent material, and active matrix refers to the technology behind the addressing of pixels.

Electrically operated display devices have developed from electromechanical systems for display of text, up to all-electronic devices capable of full-motion 3D color graphic displays. Electromagnetic devices, using a solenoid coil to control a visible flag or flap, were the earliest type, and were used for text displays such as stock market prices and arrival/departure display times. The cathode ray tube was the workhorse of text and video display technology for several decades until being displaced by plasma, liquid crystal (LCD), and solid-state devices such as thin-film transistors (TFTs), LEDs and OLEDs. With the advent of metal–oxide–semiconductor field-effect transistors (MOSFETs), integrated circuit (IC) chips, microprocessors, and microelectronic devices, many more individual picture elements ("pixels") could be incorporated into one display device, allowing graphic displays and video.

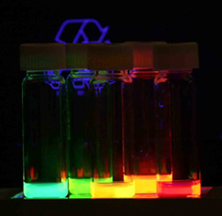

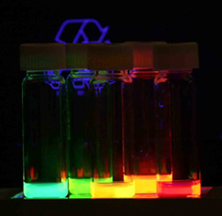

A quantum dot display is a display device that uses quantum dots (QD), semiconductor nanocrystals which can produce pure monochromatic red, green, and blue light. Photo-emissive quantum dot particles are used in LCD backlights or display color filters. Quantum dots are excited by the blue light from the display panel to emit pure basic colors, which reduces light losses and color crosstalk in color filters, improving display brightness and color gamut. Light travels through QD layer film and traditional RGB filters made from color pigments, or through QD filters with red/green QD color converters and blue passthrough. Although the QD color filter technology is primarily used in LED-backlit LCDs, it is applicable to other display technologies which use color filters, such as blue/UV active-matrix organic light-emitting diode (AMOLED) or QNED/MicroLED display panels. LED-backlit LCDs are the main application of photo-emissive quantum dots, though blue OLED panels with QD color filters are being researched.

A see-through display or transparent display is an electronic display that allows the user to see what is shown on the screen while still being able to see through it. The main applications of this type of display are in head-up displays, augmented reality systems, digital signage, and general large-scale spatial light modulation. They should be distinguished from image-combination systems which achieve visually similar effects by optically combining multiple images in the field of view. Transparent displays embed the active matrix of the display in the field of view, which generally allows them to be more compact than combination-based systems.

Low-temperature polycrystalline silicon (LTPS) is polycrystalline silicon that has been synthesized at relatively low temperatures compared to in traditional methods. LTPS is important for display industries, since the use of large glass panels prohibits exposure to deformative high temperatures. More specifically, the use of polycrystalline silicon in thin-film transistors (LTPS-TFT) has high potential for large-scale production of electronic devices like flat panel LCD displays or image sensors.