Velvet is a type of woven tufted fabric in which the cut threads are evenly distributed, with a short dense pile, giving it a distinctive soft feel. By extension, the word velvety means "smooth like velvet." Velvet can be made from either synthetic or natural fibers.

Satin is a weave that typically has a glossy surface and a dull back, one of three fundamental types of textile weaves along with plain weave and twill. The satin weave is characterized by four or more fill or weft yarns floating over a warp yarn, four warp yarns floating over a single weft yarn. Floats are missed interfacings, for example where the warp yarn lies on top of the weft in a warp-faced satin. These floats explain the high luster and even sheen, as unlike in other weaves, the light reflecting is not scattered as much by the fibres. Satin is usually a warp-faced weaving technique in which warp yarns are "floated" over weft yarns, although there are also weft-faced satins. If a fabric is formed with a satin weave using filament fibres such as silk, polyester or nylon, the corresponding fabric is termed a satin, although some definitions insist that the fabric be made from silk. If the yarns used are short-staple yarns such as cotton, the fabric formed is considered a sateen.

Poplin, also called tabinet, is a strong fabric in a plain weave of any fiber or blend, with crosswise ribs that typically give a corded surface.

Gabardine is a tough, tightly woven fabric used to make suits, overcoats, trousers, uniforms, windbreakers and other garments.

Piqué, or marcella, refers to a weaving style, normally used with cotton yarn, which is characterized by raised parallel cords or geometric designs in the fabric. Piqué fabrics vary from semi-sheer dimity to heavy weight waffle cloth. Twilled cotton and corded cotton are close relatives.

A dress shirt, button shirt, button-front, button-front shirt, or button-up shirt is a garment with a collar and a full-length opening at the front, which is fastened using buttons or shirt studs. A button-down or button-down shirt is a dress shirt which has a button-down collar – a collar having the ends fastened to the shirt with buttons.

Crêpe, also spelt crepe or crape, is a silk, wool, or synthetic fiber fabric with a distinctively crisp, crimped appearance. The term crape typically refers to a form of the fabric associated specifically with mourning. Crêpe is also historically called crespe or crisp.

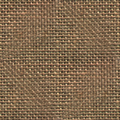

Textile manufacturing is a major industry. It is based on the conversion of fiber into yarn, yarn into fabric. These are then dyed or printed, fabricated into clothes. Different types of fibers are used to produce yarn. Cotton remains the most important natural fiber, so is treated in depth. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide ranges of products. There remains a large industry that uses hand techniques to achieve the same results.

For woven textiles, grain refers to the orientation of the weft and warp threads. The three named grains are straight grain, cross grain, and the bias grain. In sewing, a pattern piece can be cut from fabric in any orientation, and the chosen grain or orientation will affect the way the fabric hangs and stretches and thus the fit of a garment. Generally speaking a piece is said to be cut on a particular grain when the longest part of the pattern or the main seams of the finished piece are aligned with that grain. Non-woven materials such as felt, interfacing or leather do not have a grain.

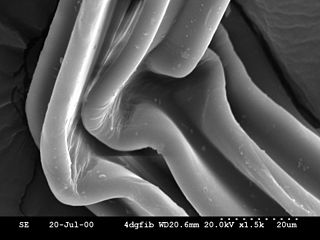

Pile weave is a form of textile created by weaving.These fabrics are characterized by a pile, a looped or tufted surface that extends above the foundation or ground weave. The pile is formed by supplemental yarn running in the direction of the length of the fabric or the width of the fabric. Pile weaves include velvet and corduroy fabrics and machine-woven Berber carpets.

Terrycloth, terry cloth, terry cotton, terry towelling, terry, terry towel or simply towelling is a fabric with loops that can absorb large amounts of water. It can be manufactured by weaving or knitting. Towelling is woven on special looms that have two beams of longitudinal warp through which the filler or weft is fired laterally. The first industrial production of terrycloth towels, in 1850, was initiated by the English manufacturer Christy. According to the Oxford English Dictionary, the word may derive from French "tiré" "drawn", past participle of "tirer" "draw out".

Knitted fabric is a textile that results from knitting. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

Silk in the Indian subcontinent is a luxury good. In India, about 97% of the raw mulberry silk is produced in the five Indian states of Karnataka, Andhra Pradesh, Tamil Nadu, West Bengal and Jammu and Kashmir. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

Ripstop fabrics are woven fabrics, often made of nylon, using a special reinforcing technique that makes them resistant to tearing and ripping. During weaving, (thick) reinforcement threads are interwoven at regular intervals in a crosshatch pattern. The intervals are typically 5 to 8 millimeters. Thin and lightweight ripstop fabrics have a 3-dimensional structure due to the thicker threads being interwoven in thinner cloth. Older lightweight ripstop fabrics display the thicker interlocking thread patterns in the material quite prominently, but more modern weaving techniques make the ripstop threads less obvious. A similar effect can be achieved by weaving two or three fine yarns together at smaller intervals.

Tattersall describes a check or plaid pattern woven into cloth. The pattern is composed of regularly-spaced thin, even vertical warp stripes, repeated horizontally in the weft, thereby forming squares.

Moire, less often moiré, is a textile with a wavy (watered) appearance produced mainly from silk, but also wool, cotton and rayon. The watered appearance is usually created by the finishing technique called calendering. Moire effects are also achieved by certain weaves, such as varying the tension in the warp and weft of the weave. Silk treated in this way is sometimes called watered silk.

Corded quilting is a decorative quilting technique popular from the late 17th through the early 19th centuries. In corded quilting, a fine fabric, sometimes colored silk but more often white linen or cotton, is backed with a loosely woven fabric. Floral or other motifs are outlined in parallel rows of running stitches or backstitches to form channels, and soft cotton cord is inserted through the backing fabric using a blunt needle and drawn along the quilted channels to produce a raised effect. Tiny quilting stitches in closely spaced rows fill the motifs and provide contrast to the corded outlines.

Eolienne is a lightweight fabric with a ribbed (corded) surface. Generally made by combining silk and cotton or silk and worsted warp and weft, it is similar to poplin but of an even lighter weight.