Knitting is a method by which yarn is manipulated to create a textile or fabric; it is used in many types of garments. Knitting may be done by hand or by machine.

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, or ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework.

Velvet is a type of woven tufted fabric in which the cut threads are evenly distributed, with a short dense pile, giving it a distinctive soft feel. By extension, the word velvety means "smooth like velvet." Velvet can be made from either synthetic or natural fibers.

Spandex, Lycra or elastane is a synthetic fiber known for its exceptional elasticity. It is a polyether-polyurea copolymer that was invented in 1958 by chemist Joseph Shivers at DuPont's Benger Laboratory in Waynesboro, Virginia.

Synthetic fiber or synthetic fibre are fibers made by humans through chemical synthesis, as opposed to natural fibers that are directly derived from living organisms. They are the result of extensive research by scientists to improve upon naturally occurring animal and plant fibers. In general, synthetic fibers are created by extruding fiber-forming materials through spinnerets, forming a fiber. These are called synthetic or artificial fibers. Synthetic fibers are created by a process known as polymerization, which involves combining monomers to make a long chain or polymer. The word polymer comes from a Greek prefix "poly" which means "many" and suffix "mer" which means "single units".. There are two types of polymerization: linear polymerization and cross-linked polymerization.

Cellulose acetate is the acetate ester of cellulose. It was first prepared in 1865. Cellulose acetate is used as a film base in photography, as a component in some coatings, and as a frame material for eyeglasses; it is also used as a synthetic fiber in the manufacture of cigarette filters and playing cards. In photographic film, cellulose acetate replaced nitrate film in the 1950s, being far less flammable and cheaper to produce.

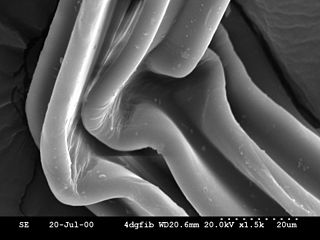

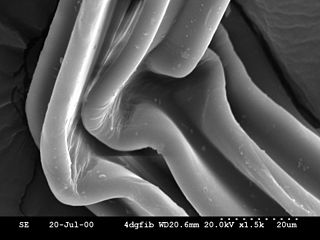

Microfiber is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. A strand of silk is about one denier and about a fifth of the diameter of a human hair.

A blouse is a loose-fitting upper garment that was worn by workmen, peasants, artists, women, and children. It is typically gathered at the waist or hips so that it hangs loosely ("blouses") over the wearer's body. Today, the word most commonly refers to a girl's or woman's dress shirt. It can also refer to a man's shirt if it is a loose-fitting style, though it rarely is. Traditionally, the term has been used to refer to a shirt which blouses out or has an unmistakably feminine appearance.

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile.

A bathrobe, also known as a housecoat, is a robe, a loose-fitting outer garment, worn by people. Bathrobes may sometimes be worn after a body wash or around a pool.

Acrylic fibers are synthetic fibers made from a polymer (polyacrylonitrile) with an average molecular weight of -100,000, about 1900 monomer units. For a fiber to be called "acrylic" in the US, the polymer must contain at least 85% acrylonitrile monomer. Typical comonomers are vinyl acetate or methyl acrylate. DuPont created the first acrylic fibers in 1941 and trademarked them under the name Orlon. It was first developed in the mid-1940s but was not produced in large quantities until the 1950s. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. It is manufactured as a filament, then cut into short staple lengths similar to wool hairs, and spun into yarn.

Polyester is a category of polymers that contain the ester functional group in their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in the cutin of plant cuticles, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. The material is used extensively in clothing.

Polar fleece is a soft napped insulating fabric made from polyester.

Layered clothing is a term describing a way of dressing using many garments that are worn on top of each other. Some of the layers have different, largely non-overlapping, functions. Using more or fewer layers, or replacing one layer but not others, allows for flexible clothing to match the needs of each situation. Two thin layers can be warmer yet lighter than one thick layer, because the air trapped between layers serves as thermal insulation. Layered clothing is particularly relevant in cold climates, where clothing must at the same time transfer moisture, provide warmth, and protect from wind and rain. In a hot and dry climate, clothes have very different functional requirements: they must block the radiation from the sun, and allow for sufficient air circulation. Therefore, layered clothing in the sense used in this article is largely irrelevant in hot and dry climates. The wicking layer moves the sweat from your skin, where it can be absorbed by the other layers.

Grosgrain, is a type of fabric or ribbon defined by the fact that its weft is heavier than its warp, creating prominent transverse ribs. It is called a "corded" fabric since the weft resembles a fine cord. Grosgrain is a plain weave corded fabric, with heavier cords than in poplin but lighter than in faille. Grosgrain has a very dull appearance with little luster but is very strong. It is a firm, close-woven, fine-corded fabric. Grosgrain fabric is most commonly available in black, but grosgrain ribbon comes in a large variety of colors and patterns. The ribbon is very similar to Petersham ribbon in its appearance, but it does not have the ability to follow the curves of a surface or edge the way that the latter does.

Charmeuse is a lightweight fabric woven with a satin weave, in which the warp threads cross over four or more of the backing (weft) threads. These float threads give the front of the fabric a smooth, shiny finish, whereas the back has a dull finish. Charmeuse differs from plain satin in that charmeuse has a different ratio of float (face) threads, and is of a lighter weight. Charmeuse may be made of silk, polyester, or Rayon. Charmeuse woven from blended fibers is becoming more common. It is used in women's clothing such as lingerie, evening gowns, and blouses, especially garments with a bias cut. It is occasionally used in menswear.

Novelty yarns include a wide variety of yarns made with unusual features, structure or fiber composition such as slubs, inclusions, metallic or synthetic fibers, laddering and varying thickness introduced during production. Some linens, wools to be woven into tweed, and the uneven filaments of some types of silk are allowed to retain their normal irregularities, producing the characteristic uneven surface of the finished fabric. Man-made fibres, which can be modified during production, are especially adaptable for special effects such as crimping and texturizing.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Historically, clothing is, and has been, made from many clothing materials. These range from grasses and furs to much more elaborate and exotic materials. Some cultures, such as the various people of the Arctic Circle, have made their clothing entirely of prepared and decorated furs and skins. Other cultures have supplemented and replaced leather and skins with cloth. Cloth is either woven or knitted, and can be made from a large variety of fibers, which in turn can be natural, cellulose, or synthetic.

In sewing, elastic is a notion which is sold in narrow strips and generally serves to increase the ability of garment to stretch, either to accommodate movement or to make the garment suitable for wearers of many different physical sizes. Elastic comes in four forms forms of construction, each with costs and benefits. The component which performs the actual stretching is made of either rubber or a synthetic material such as spandex; this stretching component is then covered with polyester, cotton, nylon, or a combination of these or other fibers which allow it to be attached to clothing. High-quality elastic is able to be stretched to twice its original length and then return to its unflexed state without showing appreciable wear.