Related Research Articles

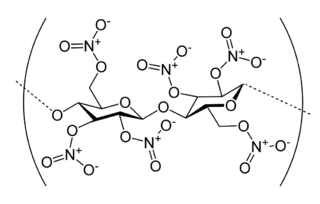

Nitrocellulose is a highly flammable compound formed by nitrating cellulose through exposure to a mixture of nitric acid and sulfuric acid. One of its first major uses was as guncotton, a replacement for gunpowder as propellant in firearms. It was also used to replace gunpowder as a low-order explosive in mining and other applications. In the form of collodion it was also a critical component in an early photographic emulsion, the use of which revolutionized photography in the 1860s. In the 20th century it was adapted to automobile lacquer and adhesives.

Rayon, also called viscose and commercialised in some countries as sabra silk or cactus silk, is a semi-synthetic fiber made from natural sources of regenerated cellulose, such as wood and related agricultural products. It has the same molecular structure as cellulose. Many types and grades of viscose fibers and films exist. Some imitate the feel and texture of natural fibers such as silk, wool, cotton, and linen. The types that resemble silk are often called artificial silk. It can be woven or knit to make textiles for clothing and other purposes.

In biochemistry, cellulose acetate refers to any acetate ester of cellulose, usually cellulose diacetate. It was first prepared in 1865. A bioplastic, cellulose acetate is used as a film base in photography, as a component in some coatings, and as a frame material for eyeglasses; it is also used as a synthetic fiber in the manufacture of cigarette filters and playing cards. In photographic film, cellulose acetate film replaced nitrate film in the 1950s, being far less flammable and cheaper to produce.

Lyocell is a semi-synthetic fiber used to make textiles for clothing and other purposes. It is a form of regenerated cellulose made by dissolving pulp and dry jet-wet spinning. Unlike rayon made by the more common viscose processes, Lyocell production does not use carbon disulfide, which is toxic to workers and the environment. Lyocell was originally trademarked as Tencel in 1982.

Sulfur dyes are the most commonly used dyes manufactured for cotton in terms of volume. They are inexpensive, generally have good wash-fastness, and are easy to apply. Sulfur dyes are predominantly black, brown, and dark blue. Red sulfur dyes are unknown, although a pink or lighter scarlet color is available.

A bathrobe, also known as a housecoat or a dressing gown, is a loose-fitting outer garment worn by people, often after washing the body or around a pool. A bathrobe is considered to be very informal clothing, and is not worn with everyday clothes.

Mercerisation is a textile finishing treatment for cellulose fabric and yarn, mainly cotton and flax, which improves dye uptake and tear strength, reduces fabric shrinkage, and imparts a silk-like luster.

A fabric softener or fabric conditioner is a conditioner applied to laundry after it has been washed in a washing machine. A similar, more dilute preparation meant to be applied to dry fabric is known as a wrinkle releaser.

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

Organdy, also spelled Organdie, is a kind of fabric. It is a lightweight, balanced plain weave made of cotton with features of sheerness and crispness.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, with color and patterns, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of coloring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Ainsworth Mill, Breightmet is a mercerising mill near the Breightmet neighborhood of Bolton, Greater Manchester. It was bought by the Lancashire Cotton Corporation in the 1940s as an attempt to develop a cotton finishing presence.

Dimensional stability pertains to a fabric's ability to maintain its initial size and shape even after undergoing wear and care, which is a desirable property. Textile manufacturing is based on the conversion of fiber into yarn, yarn into fabric, includes spinning, weaving, or knitting, etc. The fabric passes through many inevitable changes and mechanical forces during this journey. When the products are immersed in water, the water acts as a relaxing medium, and all stresses and strains are relaxed and the fabric tries to come back to its original state.

Wet Processing Engineering is one of the major streams in Textile Engineering or Textile manufacturing which refers to the engineering of textile chemical processes and associated applied science. The other three streams in textile engineering are yarn engineering, fabric engineering, and apparel engineering. The processes of this stream are involved or carried out in an aqueous stage. Hence, it is called a wet process which usually covers pre-treatment, dyeing, printing, and finishing.

Green textiles are fabrics or fibres produced to replace environmentally harmful textiles and minimise the ecological impact. Green textiles are part of the sustainable fashion and eco-friendly trends, providing alternatives to the otherwise pollution-heavy products of conventional textile industry, which is deemed the most ecologically damaging industry.

Wrinkle-resistant or permanent press or durable press is a finishing method for textiles that avoids creases and wrinkles and provides a better appearance for the articles. Most cellulosic fabrics and blends of cellulosic-rich fabrics tend to crease or wrinkle. A durable press finish makes them dimensionally stable and crease-free. The finishing includes chemical finishing as well as mechanical finishing. Wrinkle-resistant finishes were developed in the early 20th century as a way to deal with fabrics derived from cotton, rayon, and linen, which were found to wrinkle easily and retain the wrinkles. These treatments have a lasting effect on the fabric. Synthetics like polyester, nylon, acrylic, and olefin have a natural resistance to wrinkles and a greater stability since they do not absorb water as efficiently.

Fabric treatments are processes that make fabric softer, or water resistant, or enhance dye penetration after they are woven. Fabric treatments get applied when the textile itself cannot add other properties. Treatments include, scrim, foam lamination, fabric protector or stain repellent, anti microbial and flame retardant.

Hand feel is the property of fabrics related to the touch that expresses sensory comfort. It refers to the way fabrics feel against the skin or in the hand and conveys information about the cloth's softness and smoothness. Hand feel is an estimated and subjective property of different fabrics, but nowadays, hand feel could be measured and assessed statistically.

Scouring is a preparatory treatment of certain textile materials. Scouring removes soluble and insoluble impurities found in textiles as natural, added and adventitious impurities: for example, oils, waxes, fats, vegetable matter, as well as dirt. Removing these contaminants through scouring prepares the textiles for subsequent processes such as bleaching and dyeing. Though a general term, "scouring" is most often used for wool. In cotton, it is synonymously called "boiling out", and in silk, and "boiling off.

References

- 1 2 3 Joseph, Marjory L. (1992). Joseph's introductory textile science. Internet Archive. Fort Worth: Harcourt Brace Jovanovich College Publishers. p. 343. ISBN 978-0-03-050723-6.

In parchmentizing transparent or parchment like fabrics are produced from cellulosic fibers with sulfuric acid

- ↑ Woods, Michael; Woods, Mary B. (Mary Boyle) (2000). Ancient communication : from grunts to graffiti. Internet Archive. Minneapolis : Runestone Press. pp. 68, 69, 36. ISBN 978-0-8225-2996-5.

- 1 2 Collier, Billie J. (2009). Understanding textiles. Internet Archive. Upper Saddle River, N.J. : Pearson Prentice Hall. p. 458. ISBN 978-0-13-118770-2.

- ↑ Hollen, Norma R.; Saddler, Jane (1968). Textiles. Internet Archive. New York, Macmillan. pp. 139, 189.

- 1 2 J. T. Marsh (1948), "Dispersion Processes", An Introduction To Textile Finishing, pp. 121–122