Related Research Articles

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

Worsted is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead, a village in the English county of Norfolk. That village, together with North Walsham and Aylsham, formed a manufacturing centre for yarn and cloth in the 12th century, when pasture enclosure and liming rendered the East Anglian soil too rich for the older agrarian sheep breeds. In the same period, many weavers from the County of Flanders moved to Norfolk. "Worsted" yarns/fabrics are distinct from woollens : the former is considered stronger, finer, smoother, and harder than the latter.

A satin weave is a type of fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamental types of textile weaves alongside plain weave and twill weave.

Woolen or woollen is a type of yarn made from carded wool. Woolen yarn is soft, light, stretchy, and full of air. It is thus a good insulator, and makes a good knitting yarn. Woolen yarn is in contrast to worsted yarn, in which the fibers are combed to lie parallel rather than carded, producing a hard, strong yarn.

Poplin, also called tabinet, is a fine wool, cotton or silk fabric that has a vertical warp and a horizontal weft. Nowadays, the name refers to a strong material in a plain weave of any fiber or blend, with crosswise ribs that typically give a corded surface.

Ikat is a dyeing technique from Indonesia used to pattern textiles that employs resist dyeing on the yarns prior to dyeing and weaving the fabric. The term is also used to refer to related and unrelated traditions in other cultures. In Southeast Asia, where it is the most widespread, ikat weaving traditions can be divided into two general clades. The first is found among Daic-speaking peoples. The second, larger group is found among the Austronesian peoples and spread via the Austronesian expansion. Similar dyeing and weaving techniques that developed independently are also present in other regions of the world, including India, Central Asia, Japan, Africa, and the Americas

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the horizontal weft is drawn through and inserted over and under the warp. A single thread of the weft crossing the warp is called a pick. Terms vary. Each individual warp thread in a fabric is called a warp end or end.

Damask is a reversible patterned fabric of silk, wool, linen, cotton, or synthetic fibers, with a pattern formed by weaving. Damasks are woven with one warp yarn and one weft yarn, usually with the pattern in warp-faced satin weave and the ground in weft-faced or sateen weave. Twill damasks include a twill-woven ground or pattern.

Double cloth or double weave is a kind of woven textile in which two or more sets of warps and one or more sets of weft or filling yarns are interconnected to form a two-layered cloth. The movement of threads between the layers allows complex patterns and surface textures to be created.

Crêpe, also spelled crepe or crape, is a silk, wool, or synthetic fiber fabric with a distinctively crisp and crimped appearance. The term "crape" typically refers to a form of the fabric associated specifically with mourning. Crêpe was also historically called "crespe" or "crisp".

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

Linsey-woolsey is a coarse twill or plain-woven fabric woven with a linen warp and a woollen weft. Similar fabrics woven with a cotton warp and woollen weft in Colonial America were also called linsey-woolsey or wincey. The name derives from a combination of lin and wool. This textile has been known since ancient times; known as shatnez (שַׁעַטְנֵז) in Hebrew, the Torah and hence Jewish law explicitly forbade wearing it.

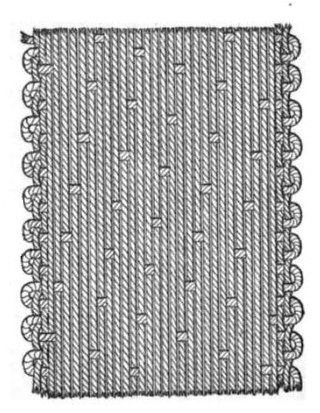

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

Silk In India, about 97% of the raw mulberry silk is produced in the Indian states of Karnataka, Andhra Pradesh, Tamil Nadu and West Bengal. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

Mockado is a woollen pile fabric made in imitation of silk velvet from the mid-sixteenth century. Mockado was usually constructed with a woollen pile on a linen or worsted wool warp and woollen weft, although the ground fabric could be any combination of wool, linen, and silk. Mockado was used for furnishings and carpeting, and also for clothing such as doublets, farthingales, and kirtles.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

Delaine was a kind of mixed cloth with cotton warp and wool in the weft. Delaines have many variations such as made of undyed yarns, and also printed or piece dyed. Delaine was a type of cloth used to manufacture women's dresses that was traded in the nineteenth century under many names to suit importers and traders. Moreover, it appeared that the plaintiffs' goods differed from delaines in various other respects.

References

- ↑ stuff, n.1, OED Second edition, 1989; online version September 2011.

- ↑ Adrian Room, "Cash, John (1822–1880)", Oxford Dictionary of National Biography , Oxford University Press, 2004

- ↑ Rosevear, Elizabeth (1893). A text-book of needlework, knitting and cutting out. Macmillan. pp. 374.

- ↑ Rosevear, Elizabeth (1893). A text-book of needlework, knitting and cutting out. Macmillan. pp. 300.

- ↑ N. Gilbert, A History of Kidderminster (Phillimore, Chichester 2004), 35-43.

- ↑ J. R. Burton, A History of Kidderminster (1890), 176-80.

- ↑ Gilbert, 55-6 59-60 66-70 77

- ↑ John James, History of the Worsted Manufacture in England (1857), passim. (substantial extract accessible via Google books); also Durham Past