Fiberglass or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Flooring is the general term for a permanent covering of a floor, or for the work of installing such a floor covering. Floor covering is a term to generically describe any finish material applied over a floor structure to provide a walking surface. Both terms are used interchangeably but floor covering refers more to loose-laid materials.

The windshield or windscreen of an aircraft, car, bus, motorbike, truck, train, boat or streetcar is the front window, which provides visibility while protecting occupants from the elements. Modern windshields are generally made of laminated safety glass, a type of treated glass, which consists of, typically, two curved sheets of glass with a plastic layer laminated between them for safety, and bonded into the window frame.

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a layered object or material assembled using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

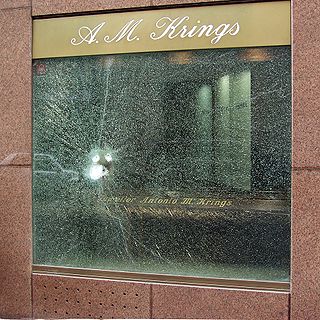

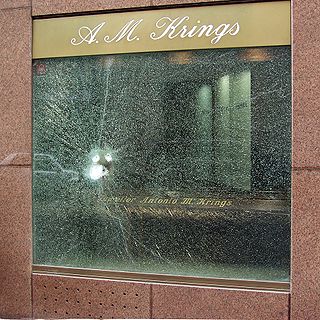

Bulletproof glass, ballistic glass, transparent armor, or bullet-resistant glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles, although, like any other material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so that it can flex instead of shatter. The index of refraction for all of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3+1⁄2 inches.

Solutia Inc. was an American manufacturer of materials and specialty chemicals including polyvinyl butyral (PVB), ethylene vinyl acetate (EVA), and thermoplastic polyurethane (TPU) interlayers for laminated glass, aftermarket window films, protective barrier and conductive films, and rubber processing chemicals. The company was formed on September 1, 1997, as a divestiture of the Monsanto Company chemical business. In July 2012, the company was acquired by Eastman Chemical Company.

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound.

Polyvinyl alcohol (PVOH, PVA, or PVAl) is a water-soluble synthetic polymer. It has the idealized formula [CH2CH(OH)]n. It is used in papermaking, textile warp sizing, as a thickener and emulsion stabilizer in polyvinyl acetate (PVAc) adhesive formulations, in a variety of coatings, and 3D printing. It is colourless (white) and odorless. It is commonly supplied as beads or as solutions in water. Without an externally added crosslinking agent, PVA solution can be gelled through repeated freezing-thawing, yielding highly strong, ultrapure, biocompatible hydrogels which have been used for a variety of applications such as vascular stents, cartilages, contact lenses, etc.

Micarta is a brand name for composites of linen, canvas, paper, fiberglass, carbon fiber, or other fabric in a thermosetting plastic. It was originally used in electrical and decorative applications. Micarta was developed by George Westinghouse at least as early as 1910 using phenolic resins invented by Leo Baekeland. These resins were used to impregnate paper and cotton fabric which were cured under pressure and high temperature to produce laminates. In later years this manufacturing method included the use of fiberglass fabric, and other resin types were also used. Today Micarta high-pressure industrial laminates are produced with a wide variety of resins and fibers. The term has been used generically for most resin impregnated fiber compounds. Common uses of modern high-pressure laminates include electrical insulators, printed circuit board substrates, and knife handles.

Safety glass is glass with additional safety features that make it less likely to break, or less likely to pose a threat when broken. Common designs include toughened glass, laminated glass, and wire mesh glass. Toughened glass was invented in 1874 by Francois Barthelemy Alfred Royer de la Bastie. Wire mesh glass was invented in 1892 by Frank Shuman. Laminated glass was invented in 1903 by the French chemist Édouard Bénédictus (1878–1930).

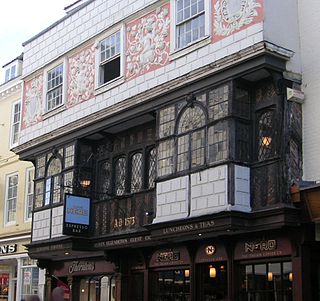

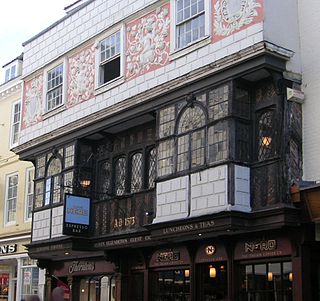

Architectural glass is glass that is used as a building material. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type, which include reinforced, toughened and laminated glasses.

Kydex is a line of thermoplastic acrylic-polyvinyl chloride materials manufactured by Sekisui SPI. It has a wide variety of applications, including for aircraft bulkheads, firearm holsters, and sheaths.

Laminated glass is a type of safety glass consisting of two or more layers of glass with one or more thin polymer interlayers between them which prevent the glass from breaking into large sharp pieces. Breaking produces a characteristic "spider web" cracking pattern when the impact is not enough to completely pierce the glass.

Clarino is a brand name for artificial leather manufactured by Kuraray. It is commonly used in garments, accessories, bags, shoes, furniture, and consumer electronics. Clarino is based on a non-woven fabric composed of synthetic fibers that are intertwined three-dimensionally. During manufacturing, it is microscopically perforated to give it breathability similar to that of natural leather. The material's softness and suppleness arise from the structure of the non-woven fabric's special fibers, superfine fiber construction and tiny cavities. Versions of Clarino are manufactured that simulate suede and top-grain leather.

The DuPont Experimental Station is the largest research and development facility of DuPont, located on the banks of the Brandywine Creek in Wilmington, Delaware

An electrochromic device (ECD) controls optical properties such as optical transmission, absorption, reflectance and/or emittance in a continual but reversible manner on application of voltage (electrochromism). This property enables an ECD to be used for applications like smart glass, electrochromic mirrors, and electrochromic display devices.

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle.

Composite glass is the collective term for a laminate having at least two glass panes which are in each case connected by means of an adhesive intermediate layer composed of plastic, e.g. by means of a casting resin or a thermoplastic composite film, which is highly tear-resistant and is viscoelastic. Composite glass should not be confused with composite windows.