Logging is the process of cutting, processing, and moving trees to a location for transport. It may include skidding, on-site processing, and loading of trees or logs onto trucks or skeleton cars. In forestry, the term logging is sometimes used narrowly to describe the logistics of moving wood from the stump to somewhere outside the forest, usually a sawmill or a lumber yard. In common usage, however, the term may cover a range of forestry or silviculture activities.

A circular saw or a buzz saw, is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

A chainsaw is a portable handheld power saw that cuts with a set of teeth attached to a rotating chain driven along a guide bar. Modern chainsaws are typically gasoline-, electric-, or battery-powered and are used in activities such as tree felling, limbing, bucking, pruning, cutting firebreaks in wildland fire suppression, harvesting of firewood, for use in chainsaw art and chainsaw mills, for cutting concrete, and cutting ice. Precursors to modern chainsaws were first used in surgery, with patents for wood chainsaws beginning in the late 19th century.

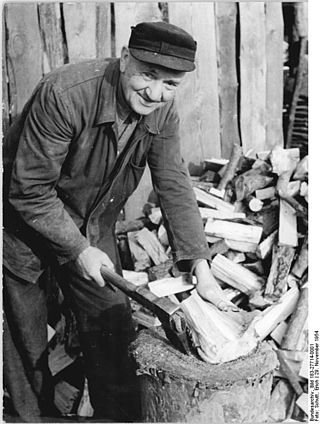

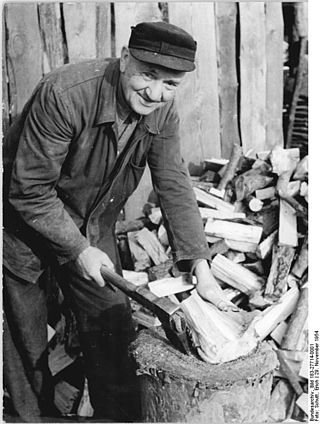

Firewood is any wooden material that is gathered and used for fuel. Generally, firewood is not heavily processed and is in some sort of recognizable log or branch form, compared to other forms of wood fuel like pellets. Firewood can be seasoned and heat treated (dry) or unseasoned (fresh/wet). It is generally classified as either hardwood or softwood.

Woodsman refers to the title of competitors participating in competitive timber sports. Woodsmen participate in various events that replicate real skills used by lumberjacks while cutting down trees and preparing the wood. Woodsman Competitions are a competitive, co-ed intercollegiate sport in the United States, Canada and elsewhere based on various skills traditionally part of forestry educational and technical training programs. In these competitions participants use various tools, such as racing axes, throwing axes, cross-cut saws, and chainsaws. In North America, the sport currently is organized in five regional divisions: northeastern, mid-Atlantic, southern, midwestern, and western.

A skidder is any type of heavy vehicle used in a logging operation for pulling cut trees out of a forest in a process called "skidding", in which the logs are transported from the cutting site to a landing. There they are loaded onto trucks, and sent to the mill. One exception is that in the early days of logging, when distances from the timberline to the mill were shorter, the landing stage was omitted altogether, and the "skidder" would have been used as the main road vehicle, in place of the trucks, railroad, or flume. Modern forms of skidders can pull trees with a cable and winch, just like the old steam donkeys, or with a hydraulic grapple either on boom or on the back of the frame (clambunk skidder).

Cut-to-length logging (CTL) is a mechanized harvesting system in which trees are delimbed and cut to length directly at the stump. CTL is typically a two-man, two-machine operation with a harvester felling, delimbing, and bucking trees and a forwarder transporting the logs from the felling to a landing area close to a road accessible by trucks.

A feller buncher is a type of harvester used in logging. It is a motorized vehicle with an attachment that can rapidly gather and cut a tree before felling it.

A harvester is a type of heavy forestry vehicle employed in cut-to-length logging operations for felling, delimbing and bucking trees. A forest harvester is typically employed together with a forwarder that hauls the logs to a roadside landing.

Limbing or delimbing is the process of removing branches from a standing or fallen tree trunk.

Wood shingles are thin, tapered pieces of wood primarily used to cover roofs and walls of buildings to protect them from the weather. Historically shingles, also known as shakes, were split from straight grained, knot free bolts of wood. Today shingles are mostly made by being cut which distinguishes them from shakes, which are made by being split out of a bolt.

The log scaler is an occupation in the timber industry. The Log Scaler measures the cut trees to determine the scale (volume) and quality (grade) of the wood to be used for manufacturing. When logs are sold, in order to determine the basis for a sale price in a standard way, the logs are "scaled" which means they are measured, identified as to species, and deductions for defects assigned to produce a net volume of merchantable wood. There are several different scales or rules that are used to determine the volume of wood. Scribner Decimal C rule is based on diagrams of circles that show the number of boards that will be utilized from the diameters of logs. The cubic rule, often called Metric in Canada, determines the cubic volume of the log material. The logs are recorded as gross scale and net scale. This occupation is usually performed by a third party organization qualified to "scale" government timber. Since internal defects are determined by external indications, scaling is not an exact science and is subject to interpretation of log scaling rules. The log scaler is subject to random "check scales" in which another scaler rescales exactly the same logs and the results are compared. The log scaler must be within + or - 1% of the gross scale and + or - 2% of the net scale to keep their certification to scale. The scale is used for payment, quality control and inventory purposes.

Axe ties are railway ties that are hewn by hand, usually with a broadaxe. There are 2,900 ties per mile of track on a first class railroad. The early railways would not accept ties cut with a saw, as it was claimed that the kerf of the saw splintered the fibres of the wood, leaving them more likely to soak up moisture causing premature rot.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The following outline is provided as an overview of and guide to forestry:

Felling is the process of cutting down trees, an element of the task of logging. The person cutting the trees is a lumberjack. A feller buncher is a machine capable of felling a single large tree or grouping and felling several small ones simultaneously.

A log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Many log splitters consist of a hydraulic pump or electric motor which then powers a hydraulic or electrical rod and piston assembly. Generally, these are often rated by the tons of force they can generate. The higher the force rating, the greater the thickness or length of the rounds that can be split. The log splitter consists of all four major hydraulic components.

A cleaving axe or cleaver is a form of axe used within green woodworking to split wood lengthways. Cleaving (riving) is used to turn a log into lumber or billets into firewood. Splitting axe is sometimes described as an old name for a splitting maul or froe.

Wood splitting is an ancient technique used in carpentry to make lumber for making wooden objects, some basket weaving, and to make firewood. Unlike wood sawing, the wood is split along the grain using tools such as a hammer and wedges, splitting maul, cleaving axe, side knife, or froe.

A firewood processor is a machine designed to cut and split firewood with minimal manual handling of the logs. There are typically four main parts of the machine, each dedicated to a separate function. Processing begins with a log pile – a pile of logs that have been de-limbed and cut to an appropriate length, generally 12–20 feet (3.7–6.1 m). Popular brands include Multitek, Eastonmade, Cord King, Wood Beaver, DYNA, Hakki Pilke, and Blockbuster. Many individuals use processors commercially, while some use them privately as a hobby. If someone has a small amount of wood they'd like to split but don't want to spend a lot of money, there's options to rent processors as an alternative to purchasing.