Related Research Articles

Pascal is an imperative and procedural programming language, designed by Niklaus Wirth as a small, efficient language intended to encourage good programming practices using structured programming and data structuring. It is named after French mathematician, philosopher and physicist Blaise Pascal.

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes.

VMEbus is a computer bus standard physically based on Eurocard sizes.

In computer architecture, cache coherence is the uniformity of shared resource data that ends up stored in multiple local caches. When clients in a system maintain caches of a common memory resource, problems may arise with incoherent data, which is particularly the case with CPUs in a multiprocessing system.

In phonetics, a diphone is an adjacent pair of phones in an utterance. For example, in [daɪfəʊn], the diphones are [da], [aɪ], [ɪf], [fə], [əʊ], [ʊn]. The term is usually used to refer to a recording of the transition between two phones.

The CDC Cyber range of mainframe-class supercomputers were the primary products of Control Data Corporation (CDC) during the 1970s and 1980s. In their day, they were the computer architecture of choice for scientific and mathematically intensive computing. They were used for modeling fluid flow, material science stress analysis, electrochemical machining analysis, probabilistic analysis, energy and academic computing, radiation shielding modeling, and other applications. The lineup also included the Cyber 18 and Cyber 1000 minicomputers. Like their predecessor, the CDC 6600, they were unusual in using the ones' complement binary representation.

Cornish wrestling is a form of wrestling that has been established in Cornwall for many centuries and possibly longer. It is similar to the Breton Gouren wrestling style. It is colloquially known as "wrasslin’" in the Cornish dialect of English; historically, this usage is attested by Chaucer, Shakespeare and Drayton.

FANUC is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. These companies are principally FANUC Corporation of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S.A. of Luxembourg.

A "production system" is a computer program typically used to provide some form of artificial intelligence, which consists primarily of a set of rules about behavior, but it also includes the mechanism necessary to follow those rules as the system responds to states of the world. Those rules, termed productions, are a basic representation found useful in automated planning, expert systems and action selection.

APT is a high-level computer programming language most commonly used to generate instructions for numerically controlled machine tools. Douglas T. Ross is considered by many to be the father of APT: as head of the newly created Computer Applications Group of the Servomechanisms Laboratory at MIT in 1956, he led its technical effort. APT is a language and system that alleviates the tedious mathematics of writing toolpaths for numerically controlled equipment. This early language was used widely through the 1970s and is still a standard internationally. Derivatives of APT were later developed.

A binary multiplier is an electronic circuit used in digital electronics, such as a computer, to multiply two binary numbers.

The P series is a series of prototype humanoid robots developed by Honda between 1993 and 2000. They were preceded by the Honda E series and followed by the ASIMO series, then the world's most advanced humanoid robots. Honda Motor's President and CEO Hiroyuki Yoshino, at the time, described Honda's humanoid robotics program as consistent with its direction to enhance human mobility.

The Integrated Truss Structure (ITS) of the International Space Station (ISS) consists of a linear arranged sequence of connected trusses on which various unpressurized components are mounted such as logistics carriers, radiators, solar arrays, and other equipment. It supplies the ISS with a bus architecture. It is approximately 110 meters long and is made from aluminium and stainless steel.

Advanced process monitor (APMonitor) is a modeling language for differential algebraic (DAE) equations. It is a free web-service or local server for solving representations of physical systems in the form of implicit DAE models. APMonitor is suited for large-scale problems and solves linear programming, integer programming, nonlinear programming, nonlinear mixed integer programming, dynamic simulation, moving horizon estimation, and nonlinear model predictive control. APMonitor does not solve the problems directly, but calls nonlinear programming solvers such as APOPT, BPOPT, IPOPT, MINOS, and SNOPT. The APMonitor API provides exact first and second derivatives of continuous functions to the solvers through automatic differentiation and in sparse matrix form.

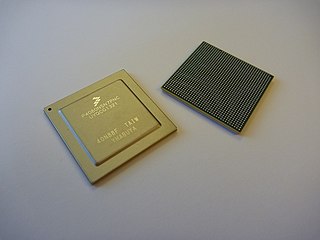

QorIQ is a brand of ARM-based and Power ISA–based communications microprocessors from NXP Semiconductors. It is the evolutionary step from the PowerQUICC platform, and initial products were built around one or more e500mc cores and came in five different product platforms, P1, P2, P3, P4, and P5, segmented by performance and functionality. The platform keeps software compatibility with older PowerPC products such as the PowerQUICC platform. In 2012 Freescale announced ARM-based QorIQ offerings beginning in 2013.

DR Radio was a division of Danish Broadcasting Corporation - DR - concerned with radio programming. The radio stations are now part of several divisions: DR Medier (P1), DR Ung (P3), DR Musik, DR Danmark.

ST Robotics is a company based in Cambridge, England, and Princeton, New Jersey, United States. The company designs and manufactures low-cost bench-top industrial robot arms and purpose built Cartesian robots. The company has no sales force and sells their robotic arm products mainly through the Internet as "boxed robots" with distributors around the world.

PackML is an industry technical standard for the control of packaging machines, as an aspect of industrial automation.

A cobot, or collaborative robot, also known as a companion robot, is a robot intended for direct human-robot interaction within a shared space, or where humans and robots are in close proximity. Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact or the humans are protected by robotic tech vests. Cobot safety may rely on lightweight construction materials, rounded edges, and inherent limitation of speed and force, or on sensors and software that ensure safe behavior.

Road signs in Ecuador are regulated in Manual Básico de Señalización Vial and Reglamento Técnico Ecuatoriano. RTE INEN 004-1:2011. Señalización vial, which is based on the United States' Manual on Uniform Traffic Control Devices (MUTCD) originally developed by the Federal Highway Administration (FHWA). Thus, road signs in Ecuador are similar in design to road signs used in the United States. One of the differences is that Ecuador uses the metric system, for example, vehicle speed is measured in km/h.

References

- ↑ "The future of robot off-line programming". CoRo Blog. 2015-10-25. Retrieved 2017-01-03.

- ↑ RoboDK. "Offline programming - RoboDK". www.robodk.com. Retrieved 2017-01-03.

- ↑ O. Nnaji, Bartholomew (1993). Theory of Automatic Robot Assembly and Programming (1993 ed.). Springer. p. 5. ISBN 978-0412393105 . Retrieved 8 February 2015.

- ↑ "Robot programming languages". Fabryka robotów. Retrieved 8 February 2015.